Outline for “Linear Bearing Slide Rail”

| Section | Subtopics |

|---|---|

| Introduction | The importance of linear bearing slide rails in precision machinery |

| What Is a Linear Bearing Slide Rail? | Definition and basic concept |

| How Linear Bearing Slide Rails Work | Motion principle and bearing mechanism |

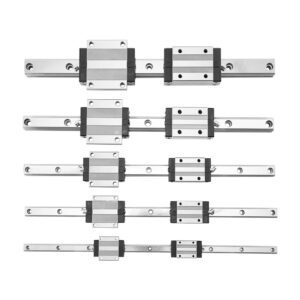

| Components of a Linear Bearing Slide Rail System | Rail, bearing block, rolling elements, seals |

| Features of YH Linear Bearing Slide Rails | Rigidity, low friction, precision, and long life |

| Types of Linear Bearing Slide Rails | Ball-type, roller-type, wide-type, miniature |

| Engineering Design and Structure | How design ensures stability and smoothness |

| Material Composition and Surface Treatment | Steel grades, coatings, and durability |

| Advantages of Linear Bearing Slide Rails | Efficiency, accuracy, and easy integration |

| Applications in Modern Industries | CNC, automation, robotics, and manufacturing |

| Comparing Linear Bearings vs. Linear Bushings | Differences in load and movement type |

| Installation Tips for Optimal Performance | Alignment, torque, and lubrication |

| Lubrication and Maintenance | Best practices for long-lasting motion systems |

| Common Issues and Solutions | Noise, vibration, or misalignment troubleshooting |

| YH Linear Bearing Slide Rail Product Line | Available models and performance highlights |

| Why Engineers Trust YH Linear | Certifications, customization, and reliability |

| Innovations in Linear Bearing Technology | Smart rails and self-lubricating systems |

| Sustainability and Manufacturing Excellence | Eco-friendly coatings and quality assurance |

| FAQs | Common user questions with detailed answers |

| Conclusion | Summary and call to action for YH Linear |

| Suggested Inbound and Outbound Links | SEO-optimized link recommendations |

Linear Bearing Slide Rail

Precision motion is the backbone of industrial automation. Among the essential components enabling such precision, the linear bearing slide rail plays a central role. It ensures smooth, accurate, and stable motion, allowing machinery to operate with maximum efficiency and minimal friction.

At YH Linear Motion Systems (https://yhlinear.com/), our linear bearing slide rails are engineered with unmatched precision, reliability, and durability — providing motion excellence across CNC machines, robotics, and high-speed automation equipment.

What Is a Linear Bearing Slide Rail?

A linear bearing slide rail is a mechanical guide system that enables linear (straight-line) motion with minimal resistance. It consists of a hardened steel rail and a bearing block (or carriage) that slides along it through internal rolling elements, such as balls or rollers.

This design drastically reduces friction compared to traditional sliding surfaces, allowing for smooth, accurate, and efficient movement even under heavy loads or high-speed operations.

How Linear Bearing Slide Rails Work

The principle behind these rails is simple yet powerful: rolling instead of sliding. Inside the bearing block, multiple steel balls or rollers circulate in raceways, carrying loads in multiple directions.

The contact angle of these rolling elements distributes forces uniformly — enabling the rail to resist moment loads, torsional forces, and vibration while maintaining accuracy. This makes linear bearing slide rails ideal for precision machining, positioning systems, and automation.

Components of a Linear Bearing Slide Rail System

| Component | Function |

|---|---|

| Guide Rail | Provides a hardened track for linear motion |

| Bearing Block (Carriage) | Moves along the rail, housing rolling elements |

| Rolling Elements (Balls/Rollers) | Minimize friction and enhance smooth motion |

| End Caps & Return Tubes | Allow circulation of rolling elements |

| Seals/Wipers | Keep dust and debris out |

| Lubrication Ports | Ensure proper lubrication and low friction |

Every component in YH Linear systems is CNC-machined and tested to ensure high repeatability, smooth operation, and low noise in industrial environments.

Features of YH Linear Bearing Slide Rails

High Rigidity and Load Capacity – Handles heavy loads while maintaining accuracy.

Smooth and Silent Operation – Optimized ball paths minimize vibration and noise.

Superior Accuracy – Micron-level positioning for CNC and robotics.

Low Friction Design – Reduces energy consumption and heat generation.

Long Lifespan – Precision-ground materials resist wear over millions of cycles.

Easy Maintenance – Built-in grease fittings simplify lubrication.

These features make YH Linear systems the preferred choice of global engineers seeking high precision and reliability.

Types of Linear Bearing Slide Rails

Ball-Type Slide Rails – Best for high-speed, low-noise applications.

Roller-Type Slide Rails – Offer enhanced rigidity and load capacity.

Wide Block Designs – Improve stability against torque and lateral force.

Miniature Linear Rails – Perfect for compact systems like 3D printers or medical devices.

YH Linear manufactures all these types to meet specific industrial demands — from lightweight automation to heavy-duty CNC systems.

Engineering Design and Structure

YH Linear rails are built using 45° contact-angle architecture, providing uniform load support in both horizontal and vertical directions. The double-row raceways ensure high rigidity, while precision grinding keeps travel deviation minimal.

Additionally, the low-profile block design reduces space consumption while maintaining superior strength — a balance that defines true engineering excellence.

Material Composition and Surface Treatment

YH Linear uses premium-grade steel and surface finishing technologies for extended life:

Alloy Steel (SUJ2) – Offers hardness and load resistance.

Stainless Steel (SUS440C) – Ensures corrosion resistance for cleanroom or medical use.

Nickel or Chrome Plating – Prevents oxidation and rust.

Teflon or Black Oxide Coating – Reduces surface friction.

Each rail undergoes heat treatment, grinding, and polishing for absolute straightness and uniformity.

Advantages of Linear Bearing Slide Rails

Reduced energy loss and operational noise

High-speed movement with minimal vibration

Consistent accuracy across long travel distances

Easy installation and interchangeability

Low maintenance requirements

Excellent long-term reliability

By adopting YH Linear’s slide rails, manufacturers can boost equipment lifespan, reduce downtime, and maintain consistent quality in production.

Applications in Modern Industries

CNC Machines & Milling Equipment

Automation Lines

Robotic Arms & Gantry Systems

Laser Cutting Machines

3D Printers and Measuring Instruments

Semiconductor and Medical Devices

YH Linear’s linear bearing slide rails are engineered for both precision and endurance, supporting industries that rely on motion perfection.

Comparing Linear Bearings vs. Linear Bushings

| Feature | Linear Bearing Slide Rail | Linear Bushing |

|---|---|---|

| Load Capacity | High | Moderate |

| Friction | Very Low | Low |

| Precision | Micron-Level | Millimeter-Level |

| Rigidity | High | Medium |

| Installation | Fixed rail system | Shaft-based |

| Applications | CNC, Robotics, Automation | Light machinery |

Installation Tips for Optimal Performance

Ensure the mounting surface flatness ≤ 0.02mm.

Tighten bolts evenly to avoid distortion.

Apply preload according to load requirements.

Use high-quality lithium grease during installation.

Test rail alignment using feeler gauges or dial indicators.

Proper alignment guarantees long service life and precise movement.

Lubrication and Maintenance

To ensure continuous performance:

Lubricate every 500–1000 hours.

Use synthetic or lithium-based grease.

Avoid moisture or dust accumulation.

Replace end seals when necessary.

YH Linear provides pre-lubricated systems that reduce downtime and enhance performance stability.

Common Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Vibration or noise | Misalignment | Recheck parallelism |

| Uneven motion | Dust contamination | Clean and re-lubricate |

| Increased friction | Dried lubrication | Apply fresh grease |

| Wear marks | Overload | Adjust system design |

YH Linear Bearing Slide Rail Product Line

YH Linear’s series includes:

H-Series (Heavy Load Type) – Enhanced rigidity for CNC.

M-Series (Medium Precision) – Ideal for automation.

Mini-Series (Compact Type) – For lightweight or small-scale equipment.

Each product is customizable for preload, coating, and length.

Why Engineers Trust YH Linear

10+ years of motion control expertise

ISO-certified production and inspection

Advanced grinding, polishing, and testing equipment

Global distribution and after-sales support

Proven reliability in industrial automation and robotics

Learn more at https://yhlinear.com/ and explore how YH Linear can elevate your machinery performance.

Innovations in Linear Bearing Technology

The next era of linear bearing slide rails will focus on:

Smart Sensors for real-time condition monitoring

Self-lubricating Materials for zero-maintenance systems

Lightweight Composite Alloys for energy efficiency

AI-Integrated Motion Systems for predictive diagnostics

YH Linear continues to lead innovation with smart precision motion solutions tailored for Industry 4.0.

Frequently Asked Questions

What is the difference between a linear bearing and a slide rail?

A linear bearing provides motion; a slide rail includes both the bearing and the guiding track for stability.

Can YH Linear slide rails handle high-speed motion?

Yes. They’re optimized for high-speed and low-vibration applications like CNC and automation.

Do I need to lubricate them frequently?

Only periodically. YH Linear rails come with built-in grease ports for easy maintenance.

Can I order customized sizes?

Absolutely. YH Linear offers OEM customization for any industrial requirement.

Are these rails corrosion-resistant?

Yes, nickel-plated and stainless options are available for harsh environments.

Where can I buy YH Linear products?

Directly from https://yhlinear.com/ or authorized distributors worldwide.

Conclusion

The linear bearing slide rail is the foundation of modern motion systems — combining precision, strength, and reliability.

YH Linear redefines excellence with advanced materials, engineering precision, and global trust. Whether you are designing automation lines or CNC machinery, YH Linear’s rails guarantee stable, accurate, and efficient motion every time.

👉 Explore the full range at https://yhlinear.com/ and discover the future of industrial motion today.

Suggested Inbound and Outbound Links

Inbound Links (YH Linear site):

Outbound Links: