Introduction

In CNC machining, precision and repeatability are non-negotiable. Whether it is milling, turning, drilling, or engraving, every movement must follow a controlled and accurate path. This is where the CNC linear guide plays a critical role.

A CNC linear guide provides smooth, precise, and stable linear motion for machine axes, ensuring high positioning accuracy, minimal friction, and long-term reliability. These guides are fundamental components in CNC machining centers, lathes, routers, and automation equipment, enabling consistent performance even under heavy loads and high-speed operation.

This article offers a comprehensive overview of CNC linear guides, including their structure, working principles, types, advantages, applications, selection criteria, and maintenance considerations.

What Is a CNC Linear Guide?

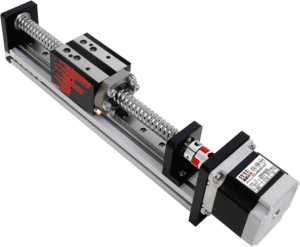

A CNC linear guide is a precision-engineered linear motion component designed to guide machine parts along a straight path with minimal resistance. It typically consists of a hardened guide rail and a bearing carriage containing rolling elements such as balls or rollers.

In CNC machines, linear guides are installed on machine axes (X, Y, and Z) to support moving components like the table, spindle head, or gantry. Their purpose is to maintain high accuracy, rigidity, and smooth motion under varying loads and speeds.

Main Components of a CNC Linear Guide System

1. Guide Rail

Precision-ground and hardened steel rail

Provides a straight, rigid reference for motion

Mounted to the machine base or frame

2. Bearing Carriage (Slider)

Moves along the rail while carrying the load

Houses rolling elements for low-friction motion

3. Rolling Elements

Recirculating steel balls or cylindrical rollers

Distribute loads evenly and reduce friction

4. End Caps, Seals, and Wipers

Prevent dust, chips, coolant, and debris from entering the guide

Extend service life and maintain accuracy

5. Lubrication System

Grease or oil ports ensure smooth and consistent operation

Critical for long-term performance in CNC environments

How CNC Linear Guides Work

CNC linear guides operate based on rolling contact motion:

The guide rail is fixed to a precisely machined mounting surface.

The bearing carriage moves along the rail.

Rolling elements circulate inside the carriage, rolling between the rail and carriage raceways.

Friction is minimized, enabling smooth and precise movement.

Loads are supported in multiple directions, including radial, axial, and moment loads.

This design allows CNC linear guides to maintain high accuracy, rigidity, and stability, even during rapid acceleration and deceleration.

Types of CNC Linear Guides

1. Ball-Type CNC Linear Guides

Use recirculating steel balls

Provide smooth motion and high precision

Suitable for most CNC machines and light-to-medium loads

2. Roller-Type CNC Linear Guides

Use cylindrical rollers instead of balls

Higher load capacity and rigidity

Ideal for heavy-duty CNC machining centers

3. Profile Rail CNC Linear Guides

Rectangular rail profile with integrated raceways

Excellent stiffness and multi-directional load support

Widely used in modern CNC equipment

4. Miniature CNC Linear Guides

Compact design for limited space

Used in desktop CNC machines, engraving machines, and small automation systems

Materials Used in CNC Linear Guides

Hardened Carbon Steel – High strength and wear resistance

Stainless Steel – Corrosion resistance for coolant-heavy or humid environments

Surface-Treated Rails – Black oxide, chrome plating, or anti-corrosion coatings

Material selection depends on cutting forces, operating environment, and machine design.

Advantages of CNC Linear Guides

High Positioning Accuracy

Low Friction and Smooth Motion

Excellent Load Capacity

High Rigidity and Stability

Reduced Wear and Longer Service Life

Improved Machining Surface Quality

Consistent Performance at High Speeds

These advantages directly impact machining accuracy, productivity, and machine reliability.

Applications of CNC Linear Guides

CNC linear guides are used in a wide range of machining and automation equipment:

CNC Milling Machines

CNC Lathes

CNC Routers and Engraving Machines

Vertical and Horizontal Machining Centers

Gantry CNC Systems

Automated Tool Changers

Robotic CNC Loading Systems

How to Select the Right CNC Linear Guide

When choosing a CNC linear guide, consider:

Load Requirements – Cutting forces and machine weight

Accuracy Class – Standard, high-precision, or ultra-precision

Travel Length – Total axis stroke

Speed and Acceleration – Rapid traverse and feed rates

Operating Environment – Chips, coolant, dust, temperature

Mounting Conditions – Flatness and rigidity of mounting surfaces

Maintenance Needs – Lubrication intervals and accessibility

Correct selection ensures stable machining accuracy and long-term performance.

Installation Best Practices

Machine mounting surfaces to required flatness and parallelism

Align rails carefully to avoid binding or uneven wear

Use specified tightening torque for rail bolts

Apply recommended lubrication before initial operation

Perform run-in procedures after installation

Proper installation is essential for achieving maximum precision and service life.

Maintenance of CNC Linear Guides

Clean rails regularly to remove chips and coolant residue

Re-lubricate according to operating conditions

Inspect seals and wipers for damage

Check for abnormal noise, vibration, or increased resistance

Regular maintenance minimizes downtime and protects machining accuracy.

Future Trends in CNC Linear Guide Technology

Higher Load and Rigidity Designs for heavy cutting applications

Integrated Condition Monitoring Sensors

Maintenance-Free or Long-Life Lubrication Systems

Advanced Coatings for Wear and Corrosion Resistance

Energy-Efficient Low-Friction Designs

These advancements support the demand for high-speed, high-precision CNC machining.

Frequently Asked Questions (FAQs)

1. Why are linear guides important in CNC machines?

They ensure accurate, stable, and smooth movement of machine axes, directly affecting machining precision.

2. What is the difference between ball and roller CNC linear guides?

Ball guides offer smooth motion and versatility, while roller guides provide higher load capacity and rigidity.

3. How long do CNC linear guides last?

With proper installation and maintenance, they can operate reliably for many years.

4. Do CNC linear guides require lubrication?

Yes, lubrication is essential to reduce wear and maintain precision.

5. Can CNC linear guides handle high-speed motion?

Yes, they are designed to perform accurately under high speed and acceleration.

Conclusion

A CNC linear guide is a cornerstone component in modern CNC machines, enabling high precision, rigidity, and smooth motion. Its performance directly affects machining accuracy, surface quality, and machine reliability.

By selecting the appropriate guide type, installing it correctly, and maintaining it properly, manufacturers can achieve consistent, high-quality CNC machining results. As CNC technology continues to evolve, linear guide systems will remain central to advancements in speed, accuracy, and automation.