Outline for Long-Form Article on Linear Guide

| Section | Sub-Headings |

|---|---|

| Introduction | Importance of linear guides in modern engineering, How linear guides revolutionized precision motion |

| Linear Guide | What is a linear guide?, History and development of linear guide systems |

| Types of Linear Guides | Ball-type linear guides, Roller-type linear guides, Flat guides, Hybrid linear guides |

| Working Principle of Linear Guide | Load distribution, Rolling vs. sliding elements |

| Advantages of Linear Guide Systems | Precision, Durability, Reduced friction, Energy efficiency |

| Linear Guide vs. Linear Rail Bearings | Key similarities, Fundamental differences, When to choose each |

| Common Applications of Linear Guides | CNC machines, Automation, 3D printing, Robotics, Medical equipment |

| Linear Guides in CNC Machines | Precision and load stability, Importance in tool paths |

| Linear Guides in Robotics | Accuracy in robotic arms, Reliability in automation |

| Linear Guides in 3D Printing | Smoother movement, High-quality layer deposition |

| Linear Guides in Medical Technology | Role in surgical robots, Imaging systems |

| Materials Used in Linear Guides | Stainless steel, Hardened alloys, Advanced coatings |

| Factors to Consider When Selecting a Linear Guide | Load capacity, Speed, Environment, Cost considerations |

| Installation of Linear Guides | Alignment requirements, Best practices, Common mistakes |

| Lubrication and Maintenance | Lubricants used, Maintenance schedules, Self-lubricating designs |

| Signs of Wear in Linear Guides | Noise, Vibration, Misalignment, Accuracy loss |

| Troubleshooting Linear Guide Issues | Common problems, Practical solutions |

| Cost of Linear Guides | Price range, Factors influencing cost, Cost vs. performance |

| Top Manufacturers of Linear Guides | THK, Hiwin, NSK, Bosch Rexroth, SKF |

| Innovations in Linear Guide Systems | Smart guides, New materials, IoT integration |

| Challenges of Linear Guides | Environmental limitations, High installation accuracy needed |

| Future of Linear Guides | Sustainability, AI-driven predictive maintenance, Advanced coatings |

| Environmental Impact of Linear Guides | Energy efficiency, Sustainable materials, Recycling |

| FAQs on Linear Guide | Practical, in-depth answers |

| Conclusion | Final insights and long-term importance |

Introduction

Every high-precision machine, from a CNC milling center to a modern 3D printer, owes part of its success to the linear guide. These mechanical components ensure smooth, controlled movement along a straight path, allowing machines to perform with remarkable precision and reliability.

In today’s world of automation and robotics, linear guides are essential. They reduce friction, improve efficiency, and enable motion accuracy that would otherwise be impossible. Without them, the precision demanded by modern industries could not be achieved.

Linear Guide

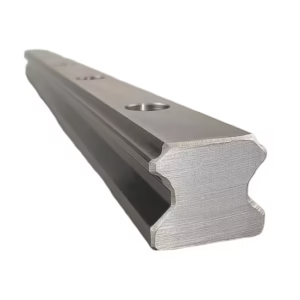

A linear guide is a mechanical system designed to provide free and precise linear movement. Unlike traditional sliding systems that generate significant friction, linear guides use rolling or advanced sliding mechanisms that ensure smooth and efficient motion.

The concept of guiding motion has existed for centuries—early craftsmen used wooden slides and grooves. Over time, as industries demanded higher accuracy, steel rails and recirculating ball systems replaced primitive methods. Today, linear guides are fundamental components in industries requiring repeatable accuracy and speed.

Types of Linear Guides

Ball-Type Linear Guides

These guides use steel balls that roll within grooves in the guide rail. The recirculating design allows continuous rolling, reducing resistance. They are commonly found in CNC machines and automation systems.

Roller-Type Linear Guides

Instead of balls, these guides employ cylindrical rollers. This increases contact area, enabling higher load-bearing capacity and stiffness. Roller guides are often used in heavy machinery.

Flat Guides

Also known as plain guides, they rely on direct sliding contact. While less precise than rolling guides, they are durable and cost-effective, particularly in dirty environments.

Hybrid Linear Guides

These combine ball and sliding systems, offering balance between high precision and durability. They are used in applications requiring special performance conditions.

Working Principle of Linear Guide

The working principle is based on reducing friction while distributing loads. The guide rail provides a track, while the carriage holds the rolling or sliding elements. As the carriage moves, rolling elements circulate continuously, ensuring smooth, consistent motion.

Compared to traditional sliding systems, this mechanism reduces wear and heat generation, making machines more efficient and reliable.

Advantages of Linear Guide Systems

Unmatched Precision: Enables accuracy in high-tech machining and robotics.

Durability: Hardened materials and recirculating systems extend life.

Low Friction: Improves energy efficiency and reduces wear.

Consistency: Reliable, repeatable performance over long cycles.

Adaptability: Works in diverse industries and environmental conditions.

Linear Guide vs. Linear Rail Bearings

While often confused, these terms have subtle differences:

Linear Rail Bearings: Typically refer to the bearing blocks that move along rails.

Linear Guides: Encompass the full guiding system, including rails and carriages.

When high precision and stiffness are required, linear guides are the preferred choice, while linear bearings may be better for lighter, simpler applications.

Common Applications of Linear Guides

Linear guides are integral to many industries:

CNC Machines: For exact tool paths and cutting precision.

Automation Systems: For conveyor systems and pick-and-place robots.

3D Printing: For smooth head movement.

Robotics: For precision in industrial automation.

Medical Devices: For surgical and imaging systems.

Linear Guides in CNC Machines

In CNC machining, accuracy is everything. Linear guides provide stable, precise movement that ensures tools cut exactly where programmed. They also withstand high-speed vibrations and heavy loads, making them critical in machining centers.

Linear Guides in Robotics

Robotics relies on accuracy and repeatability. Linear guides ensure robotic arms and automated systems can perform thousands of movements without deviation. They provide rigidity, stability, and smoothness required in automation-heavy industries.

Linear Guides in 3D Printing

3D printing requires precision at a micro-level. Linear guides improve print quality by ensuring controlled, vibration-free motion of print heads and beds. This allows consistent layer deposition and high-resolution results.

Linear Guides in Medical Technology

Medical technology demands reliability and accuracy. Linear guides are used in surgical robots, diagnostic imaging systems, and patient-handling equipment. Their smooth and precise motion helps ensure safety and accuracy in critical applications.

Materials Used in Linear Guides

Most linear guides are manufactured from:

Stainless Steel: Resistant to rust and suitable for clean environments.

Hardened Alloys: Provide strength for industrial applications.

Advanced Coatings: Reduce wear, corrosion, and improve lifespan.

Factors to Consider When Selecting a Linear Guide

Before selecting a linear guide, engineers must consider:

Load Capacity: Heavier loads require roller guides.

Speed Requirements: High-speed applications need low-friction systems.

Operating Environment: Dust, moisture, and temperature can affect performance.

Cost vs. Performance: Balancing budget with precision needs.

Installation of Linear Guides

Proper installation is vital for performance:

Ensure perfect rail alignment.

Use torque specifications recommended by manufacturers.

Avoid contamination during installation.

Even minor misalignment can cause accelerated wear and reduced accuracy.

Lubrication and Maintenance

Lubrication reduces wear and ensures smooth motion. Options include:

Oil-based lubricants: For high-speed systems.

Grease-based lubricants: For long-term, low-maintenance use.

Self-lubricating designs: Ideal for hard-to-maintain environments.

Regular maintenance includes cleaning, relubrication, and inspection for wear.

Signs of Wear in Linear Guides

Common symptoms of wear include:

Increased noise during motion.

Vibration or jerky movement.

Misalignment or track deviation.

Reduction in precision or repeatability.

Troubleshooting Linear Guide Issues

Noise: Often caused by contamination or lack of lubrication.

Vibration: Usually indicates misalignment.

Loss of accuracy: Could mean worn-out rolling elements.

Quick corrective measures can extend guide life significantly.

Cost of Linear Guides

Linear guide costs vary based on quality, brand, and application:

Small-scale guides: $50–$200.

Industrial-grade guides: $500–$2000.

Specialized medical/robotics guides: $2000+.

Investing in higher-quality guides saves long-term costs through reduced downtime and better precision.

Top Manufacturers of Linear Guides

Trusted global manufacturers include:

THK (Japan) – Pioneer in precision linear guides.

Hiwin (Taiwan) – Affordable yet reliable guides.

NSK (Japan) – Renowned for high-quality bearings and guides.

Bosch Rexroth (Germany) – Premium automation solutions.

SKF (Sweden) – Global leader in motion systems.

Innovations in Linear Guide Systems

Modern innovations include:

Smart Guides: Equipped with sensors for monitoring wear.

Lightweight Designs: Using composites and aluminum alloys.

IoT Integration: For predictive maintenance and performance tracking.

Challenges of Linear Guides

Despite their advantages, linear guides face challenges:

High installation precision required.

Cost can be prohibitive for smaller applications.

Contamination risk in dirty environments.

Future of Linear Guides

The future of linear guides is shaped by:

AI-driven predictive maintenance.

Eco-friendly materials and coatings.

Integration with robotics and automation systems.

Their role in Industry 4.0 will only grow stronger.

Environmental Impact of Linear Guides

Linear guides help reduce energy consumption by lowering friction. Manufacturers are now using recyclable materials and eco-friendly lubricants, reducing their environmental footprint.

FAQs on Linear Guide

What is the purpose of a linear guide?

To ensure smooth, precise movement along a straight path.

What’s the difference between a linear guide and linear rail bearing?

A linear guide includes the entire guiding system, while a linear rail bearing is the block that moves along the rail.

Do linear guides need lubrication?

Yes, lubrication is essential for reducing wear and ensuring smooth performance.

Can linear guides handle heavy loads?

Yes, roller-type linear guides are built for heavy-duty industrial use.

Are linear guides expensive?

They range from affordable entry-level systems to high-cost industrial solutions.

What industries use linear guides?

CNC machining, robotics, 3D printing, automation, and medical equipment.

Conclusion

The linear guide is one of the most important components in modern precision engineering. It ensures efficiency, accuracy, and durability in countless industries, from robotics to healthcare. As technology advances, linear guides will become smarter, more durable, and more eco-friendly, further enhancing their importance in Industry 4.0 and beyond.

For engineers, manufacturers, and innovators, investing in high-quality linear guides is not just a choice—it is a necessity for achieving long-term precision and reliability.

Suggested Inbound Links

CNC machining processes explained

Benefits of industrial robotics

3D printing advancements