Outline for Long-Form Article on Linear Ball Bearing

| Section | Sub-Headings |

|---|---|

| Introduction | Importance of linear ball bearings, How they changed precision engineering |

| Linear Ball Bearing | What is a linear ball bearing?, Evolution of linear bearings |

| Design of Linear Ball Bearings | Structure and components, Working principle |

| Types of Linear Ball Bearings | Open linear ball bearings, Closed linear ball bearings, Adjustable bearings, Self-aligning linear ball bearings |

| How Linear Ball Bearings Work | Ball recirculation system, Load distribution, Reducing friction |

| Advantages of Linear Ball Bearings | High precision, Smooth motion, Cost efficiency, Durability |

| Limitations of Linear Ball Bearings | Load capacity, Contamination sensitivity, Noise at high speeds |

| Linear Ball Bearings vs. Linear Bushings | Key differences, When to choose each |

| Common Applications of Linear Ball Bearings | CNC machines, 3D printers, Automation, Robotics, Packaging systems |

| Linear Ball Bearings in CNC Machines | Precise tool movement, Load stability |

| Linear Ball Bearings in 3D Printing | Smooth print head motion, Improved accuracy |

| Linear Ball Bearings in Robotics | Accuracy in robotic arms, Motion reliability |

| Linear Ball Bearings in Medical Equipment | Use in diagnostic machines, Surgical robots |

| Materials Used in Linear Ball Bearings | Hardened steel, Stainless steel, Polymer cages |

| Factors to Consider When Choosing Linear Ball Bearings | Load, Speed, Environment, Maintenance |

| Installation of Linear Ball Bearings | Alignment considerations, Mounting techniques |

| Lubrication and Maintenance | Oils and greases, Self-lubricating options, Maintenance intervals |

| Signs of Wear in Linear Ball Bearings | Noise, Vibration, Reduced accuracy |

| Troubleshooting Linear Ball Bearings | Common issues, Easy fixes |

| Cost of Linear Ball Bearings | Price ranges, Factors influencing cost |

| Top Manufacturers of Linear Ball Bearings | THK, Hiwin, NSK, Bosch Rexroth, SKF |

| Innovations in Linear Ball Bearings | Smart bearings, Advanced coatings, Lightweight materials |

| Future of Linear Ball Bearings | Sustainability, IoT integration, AI-driven predictive maintenance |

| Environmental Impact of Linear Ball Bearings | Energy efficiency, Recyclable materials, Green lubrication |

| FAQs on Linear Ball Bearings | Practical and detailed answers |

| Conclusion | Final insights on their importance |

Introduction

In modern engineering, where precision and efficiency are non-negotiable, the linear ball bearing stands as a cornerstone of smooth linear motion. Found in CNC machines, 3D printers, robotics, and even medical devices, these bearings allow parts to glide seamlessly along shafts with minimal friction.

Without linear ball bearings, industries would face excessive wear, inefficiency, and imprecision. Their simplicity hides their sophistication—a recirculating system of steel balls inside a bearing housing ensures smooth, accurate, and durable movement along a straight axis.

Linear Ball Bearing

A linear ball bearing is a type of bearing that provides free linear motion by using a series of small steel balls. These balls roll between an outer race and a cylindrical shaft, minimizing friction while ensuring high precision.

The concept originated in the early 20th century when industries sought alternatives to sliding bushings. Over the decades, advancements in materials and design have made linear ball bearings indispensable across multiple sectors.

Design of Linear Ball Bearings

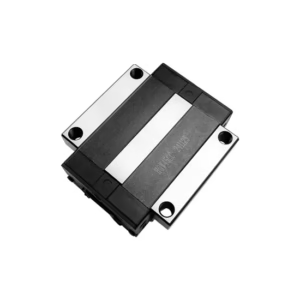

The typical structure includes:

Outer Shell: Cylindrical housing that holds the bearing assembly.

Ball Retainer/Cage: Keeps steel balls evenly distributed.

Recirculating Steel Balls: Provide smooth rolling action.

End Seals: Prevent dirt and dust from entering.

This design allows for continuous motion without excessive friction or wear.

Types of Linear Ball Bearings

Open Linear Ball Bearings

These do not cover the entire circumference, allowing them to be mounted on shafts with supported rails.

Closed Linear Ball Bearings

Fully enclosed designs suitable for use with unsupported shafts.

Adjustable Linear Bearings

Designed to allow clearance adjustments, useful for compensating for wear.

Self-Aligning Linear Ball Bearings

Can accommodate minor shaft misalignments, ensuring smoother operation.

How Linear Ball Bearings Work

The principle is simple yet effective. As the shaft moves, steel balls roll along its surface. Once they reach one end, the recirculation system returns them to the starting point.

This recirculating ball mechanism ensures constant rolling motion, preventing sticking and significantly reducing friction compared to plain bushings.

Advantages of Linear Ball Bearings

High Precision: Ideal for CNC machines and robotics.

Smooth Motion: Minimal friction ensures consistent performance.

Cost Efficiency: Affordable compared to more complex systems.

Durability: Hardened steel construction extends service life.

Low Maintenance: Requires only periodic lubrication.

Limitations of Linear Ball Bearings

Despite their advantages, they have limitations:

Lower Load Capacity: Compared to roller bearings.

Contamination Sensitivity: Dust and dirt can disrupt ball movement.

Noise at High Speeds: Recirculating balls can generate noise in fast-moving systems.

Linear Ball Bearings vs. Linear Bushings

Linear Ball Bearings: Use rolling balls, reduce friction, more precise.

Linear Bushings: Use sliding contact, cheaper but less precise.

If accuracy and smoothness are top priorities, linear ball bearings are the better option.

Common Applications of Linear Ball Bearings

CNC Machines: For tool positioning and precision cutting.

3D Printers: Ensuring stable and vibration-free head movement.

Automation Systems: Used in packaging, assembly, and conveyors.

Robotics: Precision movement in robotic arms.

Medical Equipment: Diagnostic scanners and surgical instruments.

Linear Ball Bearings in CNC Machines

CNC machines rely heavily on linear ball bearings for accurate tool paths. These bearings allow smooth sliding along shafts, ensuring repeatable precision in cutting, milling, and drilling.

Linear Ball Bearings in 3D Printing

In 3D printing, even the smallest vibration can affect print quality. Linear ball bearings help maintain stable, precise motion, leading to sharper and cleaner prints.

Linear Ball Bearings in Robotics

Robotic arms and automated equipment need smooth, repeatable movements. Linear ball bearings provide the accuracy and rigidity needed to maintain consistent performance over thousands of cycles.

Linear Ball Bearings in Medical Equipment

Medical devices require controlled, safe motion. Linear ball bearings enable smooth operation in MRI machines, diagnostic tools, and surgical robots, where precision is critical.

Materials Used in Linear Ball Bearings

Hardened Steel: High strength and wear resistance.

Stainless Steel: Corrosion resistance for clean environments.

Polymer Cages: Reduce noise and improve durability.

Factors to Consider When Choosing Linear Ball Bearings

Load Capacity: Heavier loads may require roller bearings instead.

Speed: High-speed applications demand low-friction designs.

Environment: Dust and moisture may require sealed bearings.

Maintenance Requirements: Consider self-lubricating options for low-maintenance systems.

Installation of Linear Ball Bearings

Proper installation ensures performance and longevity:

Align shafts precisely.

Avoid excessive tightening.

Ensure bearings slide smoothly without binding.

Lubrication and Maintenance

Lubrication is key to preventing wear:

Oil-based lubricants: Suitable for high-speed applications.

Grease-based lubricants: Provide longer-lasting lubrication.

Self-lubricating designs: Minimize maintenance needs.

Regular maintenance includes cleaning, relubrication, and replacing worn bearings.

Signs of Wear in Linear Ball Bearings

Grinding noise during operation.

Increased vibration.

Play or looseness in motion.

Reduced accuracy in machine performance.

Troubleshooting Linear Ball Bearings

Noise: Check lubrication and contamination.

Vibration: Ensure proper shaft alignment.

Reduced accuracy: Inspect for wear or damage.

Simple corrective steps often restore functionality.

Cost of Linear Ball Bearings

Pricing depends on size, quality, and brand:

Small bearings: $5–$50.

Medium-grade bearings: $50–$200.

Industrial-grade bearings: $200+.

Affordable yet effective, they remain popular across industries.

Top Manufacturers of Linear Ball Bearings

THK (Japan) – Renowned for high-quality bearings.

Hiwin (Taiwan) – Popular for affordability and reliability.

NSK (Japan) – Leader in precision bearings.

Bosch Rexroth (Germany) – Premium automation solutions.

SKF (Sweden) – A trusted global bearing manufacturer.

Innovations in Linear Ball Bearings

Recent innovations include:

Smart Bearings: Sensors for real-time monitoring.

Advanced Coatings: Reduce wear and friction.

Lightweight Materials: Composites for reduced system weight.

Future of Linear Ball Bearings

The future points toward:

IoT-enabled monitoring systems.

Eco-friendly lubricants.

AI-driven predictive maintenance.

These trends will make linear ball bearings even more efficient and sustainable.

Environmental Impact of Linear Ball Bearings

Linear ball bearings reduce energy consumption by minimizing friction. Many manufacturers now use recyclable materials and eco-friendly lubricants, contributing to sustainable engineering practices.

FAQs on Linear Ball Bearings

What is a linear ball bearing used for?

It enables smooth, precise motion along a straight shaft.

Do linear ball bearings need lubrication?

Yes, lubrication is essential for performance and longevity.

Can they handle heavy loads?

They are best suited for light to medium loads. For heavy-duty use, roller bearings are preferred.

Are linear ball bearings noisy?

At high speeds, they can produce some noise, but proper lubrication reduces it.

How long do linear ball bearings last?

With proper care, they can last years under normal operating conditions.

What industries use linear ball bearings?

CNC machining, 3D printing, robotics, packaging, and medical equipment.

Conclusion

The linear ball bearing is a simple yet highly effective component that powers precision engineering across industries. Its ability to reduce friction, ensure accuracy, and provide smooth motion makes it a critical element in CNC machines, robotics, automation, and medical devices.

While not suited for extremely heavy loads, linear ball bearings excel in speed, precision, and affordability. With innovations in smart monitoring and eco-friendly materials, they are set to play an even more important role in the future of motion systems.

Investing in high-quality linear ball bearings today means investing in long-term precision, durability, and efficiency.

Suggested Inbound Links

Benefits of CNC machining

Guide to automation technologies

Introduction to robotics engineering