Outline for Long-Form Article on Linear Bearing Block

| Section | Sub-Headings |

|---|---|

| Introduction | Importance of linear bearing blocks, Role in precision engineering |

| Linear Bearing Block | What is a linear bearing block?, Historical development |

| Design and Structure of Linear Bearing Blocks | Rail and block system, Rolling element design, End caps and seals |

| Types of Linear Bearing Blocks | Standard linear blocks, Flange-type blocks, Slim-type blocks, Self-aligning blocks |

| Working Principle of Linear Bearing Blocks | Rolling mechanism, Load distribution, Friction reduction |

| Advantages of Linear Bearing Blocks | Precision, Rigidity, Durability, Energy efficiency |

| Limitations of Linear Bearing Blocks | Cost, Installation accuracy, Contamination risks |

| Linear Bearing Block vs. Linear Guide Block | Key similarities, Fundamental differences |

| Common Applications of Linear Bearing Blocks | CNC machines, 3D printers, Robotics, Packaging equipment, Medical devices |

| Linear Bearing Blocks in CNC Machines | Accuracy in tool movement, Load handling |

| Linear Bearing Blocks in 3D Printing | Smooth print head travel, High-quality layer accuracy |

| Linear Bearing Blocks in Robotics | Reliability in robotic arms, Automation precision |

| Linear Bearing Blocks in Medical Technology | Imaging equipment, Surgical robots |

| Materials Used in Linear Bearing Blocks | Hardened steel, Stainless steel, Aluminum alloys |

| Factors to Consider When Choosing Linear Bearing Blocks | Load, Speed, Environment, Maintenance needs |

| Installation of Linear Bearing Blocks | Alignment, Mounting practices, Avoiding misalignment |

| Lubrication and Maintenance of Linear Bearing Blocks | Oils, Greases, Self-lubricating designs |

| Signs of Wear in Linear Bearing Blocks | Noise, Rough motion, Accuracy loss |

| Troubleshooting Linear Bearing Block Issues | Common problems, Easy solutions |

| Cost of Linear Bearing Blocks | Price ranges, Factors affecting cost |

| Top Manufacturers of Linear Bearing Blocks | THK, Hiwin, NSK, Bosch Rexroth, SKF |

| Innovations in Linear Bearing Block Technology | Smart monitoring, Advanced coatings, Lightweight designs |

| Future of Linear Bearing Blocks | AI-driven predictive maintenance, Eco-friendly designs |

| Environmental Impact of Linear Bearing Blocks | Energy savings, Recycling, Green lubrication |

| FAQs on Linear Bearing Blocks | Practical answers to common questions |

| Conclusion | Final insights on their importance |

Introduction

Modern machinery relies heavily on components that ensure smooth, precise, and controlled motion. Among these, the linear bearing block is one of the most crucial. Found in CNC machines, 3D printers, robotics, and medical devices, linear bearing blocks enable accurate linear movement while supporting significant loads.

Without them, industries would face inefficiency, reduced accuracy, and higher maintenance costs. These blocks combine advanced engineering with practical durability, making them indispensable in today’s high-performance applications.

Linear Bearing Block

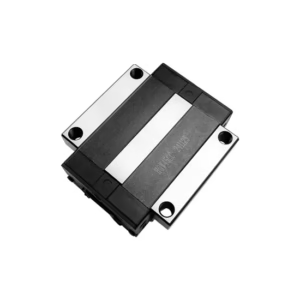

A linear bearing block is a component that slides along a linear guide rail, using rolling elements like steel balls or rollers to minimize friction. It serves as the moving carriage that holds loads while ensuring smooth linear travel.

Historically, industries used plain sliding mechanisms. However, with rising demands for automation and CNC machining, recirculating ball-type bearing blocks became the gold standard for precision and reliability.

Design and Structure of Linear Bearing Blocks

A typical linear bearing block consists of:

Carriage Housing: The block body that travels along the rail.

Rolling Elements: Recirculating steel balls or rollers for smooth motion.

End Caps and Seals: Prevent contamination and retain lubrication.

Load Surfaces: Contact areas designed to handle heavy loads without deformation.

This design ensures rigidity, stability, and long operational life.

Types of Linear Bearing Blocks

Standard Linear Blocks

Widely used in CNC machines, offering balanced performance for general applications.

Flange-Type Blocks

Feature extended mounting surfaces, ideal for stability and easy installation.

Slim-Type Blocks

Compact designs for space-saving applications like 3D printers.

Self-Aligning Blocks

Designed to compensate for slight misalignments in rail installations.

Working Principle of Linear Bearing Blocks

Linear bearing blocks work by allowing rolling elements inside the block to circulate along grooves in the guide rail. This rolling motion reduces friction drastically compared to sliding mechanisms.

Load is distributed across multiple contact points, which enhances precision, rigidity, and longevity.

Advantages of Linear Bearing Blocks

High Precision: Essential for CNC cutting, robotics, and automation.

Rigidity: Provides stability under heavy loads.

Durability: Long service life thanks to hardened rails and blocks.

Efficiency: Smooth motion reduces motor power consumption.

Versatility: Useful in both light-duty and heavy-duty applications.

Limitations of Linear Bearing Blocks

High Cost: Precision components are more expensive.

Installation Accuracy: Requires perfect alignment to avoid premature wear.

Contamination Risk: Dust and dirt can cause early failure if not sealed.

Linear Bearing Block vs. Linear Guide Block

While both terms are often used interchangeably, subtle distinctions exist:

Linear Bearing Block: Focuses on the bearing carriage that houses rolling elements.

Linear Guide Block: Refers to the complete guiding system, including rail and block.

In practice, engineers often use both terms when referring to linear motion assemblies.

Common Applications of Linear Bearing Blocks

CNC Machines: For precision tool positioning.

3D Printers: Ensuring accurate and vibration-free movement.

Robotics: Enabling precise robotic arm control.

Packaging Equipment: Smooth conveyor and pick-and-place movement.

Medical Devices: Reliable operation in imaging and surgical equipment.

Linear Bearing Blocks in CNC Machines

CNC machining demands high precision and rigidity. Linear bearing blocks support heavy loads while ensuring smooth tool paths, enabling accurate cuts and reduced vibrations.

Linear Bearing Blocks in 3D Printing

In 3D printing, precision is critical. Linear bearing blocks enable smooth head and bed motion, ensuring high-quality prints with consistent layer alignment.

Linear Bearing Blocks in Robotics

Robotic arms rely on linear bearing blocks for accuracy and repeatability. They ensure precise movements, whether in industrial automation or collaborative robots.

Linear Bearing Blocks in Medical Technology

Medical technology requires safety and reliability. Linear bearing blocks are used in surgical robots, MRI scanners, and patient-handling systems, where stability and smooth motion are vital.

Materials Used in Linear Bearing Blocks

Hardened Steel: Provides strength and load capacity.

Stainless Steel: Resistant to corrosion, ideal for cleanroom environments.

Aluminum Alloys: Lightweight, often used in compact systems.

Factors to Consider When Choosing Linear Bearing Blocks

Load Capacity: Choose based on application requirements.

Speed: High-speed operations require low-friction bearings.

Environment: Contaminants, moisture, or extreme temperatures affect performance.

Maintenance: Consider lubrication needs and accessibility.

Installation of Linear Bearing Blocks

Best practices include:

Ensuring rails are perfectly aligned.

Using manufacturer-recommended torque.

Avoiding contamination during installation.

Improper installation can drastically reduce bearing life.

Lubrication and Maintenance of Linear Bearing Blocks

Lubrication is critical for performance:

Grease lubrication: Long-term performance with minimal maintenance.

Oil lubrication: Ideal for high-speed systems.

Self-lubricating options: Useful for hard-to-access applications.

Maintenance should include periodic cleaning and relubrication.

Signs of Wear in Linear Bearing Blocks

Grinding or unusual noise.

Increased vibration.

Reduced motion accuracy.

Visible scoring on rails or blocks.

Troubleshooting Linear Bearing Block Issues

Noise: Check lubrication and contamination.

Vibration: Inspect for misalignment.

Reduced precision: Replace worn bearings.

Quick fixes prevent costly machine downtime.

Cost of Linear Bearing Blocks

The price varies by type, size, and brand:

Entry-level blocks: $30–$100.

Mid-range blocks: $100–$500.

High-precision industrial blocks: $500–$2000+.

While costly, they save money in the long term through reliability and reduced downtime.

Top Manufacturers of Linear Bearing Blocks

THK (Japan) – Industry leader in linear motion.

Hiwin (Taiwan) – Reliable and cost-effective solutions.

NSK (Japan) – High-performance designs.

Bosch Rexroth (Germany) – Premium-quality automation products.

SKF (Sweden) – Trusted global motion systems brand.

Innovations in Linear Bearing Block Technology

Recent innovations include:

Smart Blocks: Sensors for real-time monitoring.

Advanced Coatings: To reduce friction and corrosion.

Lightweight Materials: Aluminum and composites for energy savings.

Future of Linear Bearing Blocks

The future is defined by:

AI-driven predictive maintenance.

Eco-friendly lubricants and recyclable materials.

Integration with Industry 4.0 and IoT systems.

These advancements will make bearing blocks smarter, more sustainable, and longer lasting.

Environmental Impact of Linear Bearing Blocks

Linear bearing blocks reduce energy consumption by lowering friction. Many manufacturers are now adopting eco-friendly lubricants and using recyclable materials, contributing to sustainability in manufacturing.

FAQs on Linear Bearing Blocks

What is a linear bearing block used for?

It allows smooth, precise movement along a guide rail while supporting loads.

Do linear bearing blocks need lubrication?

Yes, regular lubrication is necessary to reduce wear.

Can they handle heavy loads?

Yes, especially roller-type blocks designed for industrial use.

Are linear bearing blocks expensive?

They vary widely in price, from affordable models to costly industrial-grade versions.

What industries use them?

CNC machining, robotics, automation, medical equipment, and 3D printing.

How long do they last?

With proper maintenance, they can last several years under continuous use.

Conclusion

The linear bearing block is a vital element in modern precision engineering. By providing smooth, accurate, and reliable linear motion, it empowers industries from CNC machining to healthcare.

As smart technologies and eco-friendly innovations reshape the future, linear bearing blocks will continue to evolve, ensuring greater efficiency, durability, and sustainability. For any engineer or manufacturer seeking long-term precision and reliability, investing in high-quality linear bearing blocks is a smart decision.

Suggested Inbound Links

CNC machining technologies

Robotics in automation

3D printing precision guide