Outline for Long-Form Article on Ball Bearing Linear

| Section | Sub-Headings |

|---|---|

| Introduction | Importance of linear motion, Role of ball bearing linear systems |

| Ball Bearing Linear | What is a ball bearing linear system?, Evolution of ball bearing technology |

| Design of Ball Bearing Linear Systems | Rail structure, Ball circulation system, Carriage housing |

| Types of Ball Bearing Linear Systems | Recirculating ball bearings, Open ball bearing linear guides, Compact linear bearings, Double-shaft linear systems |

| Working Principle of Ball Bearing Linear Guides | Rolling mechanism, Load distribution, Friction reduction |

| Advantages of Ball Bearing Linear Systems | High precision, Rigidity, Long service life, Energy efficiency |

| Ball Bearing Linear vs. Plain Linear Bearings | Performance comparison, Cost analysis, Application suitability |

| Applications of Ball Bearing Linear Systems | CNC machines, 3D printers, Robotics, Automation, Medical technology |

| Ball Bearing Linear in CNC Machines | Accuracy in machining, Heavy load support |

| Ball Bearing Linear in 3D Printing | Smoother travel, Higher print quality |

| Ball Bearing Linear in Robotics | Precision in robotic arms, Automation flexibility |

| Ball Bearing Linear in Medical Devices | Diagnostic equipment, Surgical robots |

| Materials Used in Ball Bearing Linear Systems | Hardened steel, Stainless steel, Polymer cages |

| Key Factors in Choosing Ball Bearing Linear Systems | Load, Speed, Environment, Maintenance |

| Installation of Ball Bearing Linear Systems | Rail alignment, Carriage mounting, Common mistakes |

| Lubrication and Maintenance | Grease vs. oil, Lubrication intervals, Self-lubricating designs |

| Signs of Wear in Ball Bearing Linear Systems | Noise, Vibration, Reduced accuracy |

| Troubleshooting Common Issues | Misalignment, Contamination, Excessive friction |

| Cost of Ball Bearing Linear Systems | Price ranges, Factors affecting cost |

| Top Manufacturers | THK, Hiwin, NSK, Bosch Rexroth, SKF |

| Innovations in Ball Bearing Linear Technology | Smart sensors, Advanced coatings, Lightweight materials |

| Future of Ball Bearing Linear Systems | IoT integration, Predictive maintenance, Sustainable materials |

| Environmental Impact | Energy savings, Recyclable components, Green lubricants |

| FAQs | Practical answers to common queries |

| Conclusion | Final insights and importance in modern industry |

Introduction

Smooth, accurate, and reliable motion is the foundation of modern automation and precision engineering. At the heart of many high-performance machines lies the ball bearing linear system, designed to provide frictionless linear movement while supporting substantial loads. From CNC machines and 3D printers to robotic arms and medical devices, ball bearing linear guides have become indispensable for industries seeking speed and accuracy.

Ball Bearing Linear

A ball bearing linear system is a linear motion mechanism that uses rolling elements—specifically steel balls—that circulate within a carriage moving along a rail. Unlike plain linear bearings, which rely on sliding contact, ball bearing linear systems minimize resistance by rolling, enabling smooth, precise, and efficient motion.

This technology evolved alongside the need for greater accuracy in manufacturing and automation. While early systems relied on sliding bearings, today’s recirculating ball-bearing linear guides dominate due to their durability, rigidity, and long lifespan.

Design of Ball Bearing Linear Systems

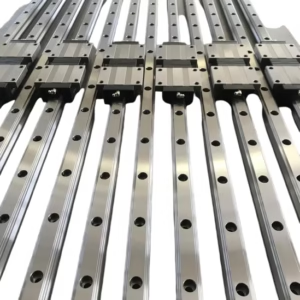

The structure of a ball bearing linear system typically includes:

Rail: A precision-ground track on which the carriage slides.

Carriage Housing: The block that holds the rolling elements.

Ball Circulation Channels: Allow balls to recirculate endlessly inside the carriage.

Seals and Caps: Protect against dust, debris, and lubricant loss.

This design provides rigidity, reduces vibration, and ensures consistent accuracy.

Types of Ball Bearing Linear Systems

Recirculating Ball Bearings

The most common type, ideal for CNC machines and robotics.

Open Ball Bearing Linear Guides

Designed for applications requiring support shafts, often used in 3D printers.

Compact Linear Bearings

Slim, space-saving designs for lightweight machinery.

Double-Shaft Linear Systems

Offer higher rigidity and load capacity, used in heavy-duty automation.

Working Principle of Ball Bearing Linear Guides

The principle is simple yet powerful:

Steel balls roll between the rail and the carriage, reducing contact friction.

As the carriage moves, balls circulate through internal channels, returning seamlessly to the contact zone.

Load is distributed across multiple contact points, minimizing wear and extending system life.

This rolling mechanism provides both precision and durability.

Advantages of Ball Bearing Linear Systems

High Precision: Ensures accurate tool positioning in CNC machining.

Rigidity: Withstands heavy loads without deflection.

Durability: Long service life due to hardened steel construction.

Efficiency: Low friction reduces motor energy consumption.

Smooth Operation: Quiet, stable, and consistent movement.

Ball Bearing Linear vs. Plain Linear Bearings

Ball Bearing Linear: Lower friction, higher precision, but higher cost.

Plain Linear Bearings: Lower cost, better for dirty environments, but less accurate.

Choosing between them depends on whether precision or durability in harsh conditions is the priority.

Applications of Ball Bearing Linear Systems

CNC Machines: Precision cutting and milling.

3D Printers: Ensures smooth print head movement.

Robotics: Provides reliable arm and joint motion.

Automation: Streamlines industrial assembly processes.

Medical Devices: Enables delicate yet precise operations.

Ball Bearing Linear in CNC Machines

CNC tools require micron-level accuracy. Ball bearing linear systems provide the rigidity and precision necessary to maintain tool paths, even under heavy cutting forces.

Ball Bearing Linear in 3D Printing

The quality of a 3D print depends on consistent layer alignment. Ball bearing linear guides help minimize vibration and provide smooth print head movement, leading to higher-quality prints.

Ball Bearing Linear in Robotics

In robotics, precision and repeatability are critical. Ball bearing linear systems enable robotic arms to perform tasks with speed, accuracy, and stability.

Ball Bearing Linear in Medical Devices

Ball bearing linear systems are used in surgical robots, MRI scanners, and diagnostic machines where smooth and precise motion is essential for patient safety and effective treatment.

Materials Used in Ball Bearing Linear Systems

Hardened Steel: Provides strength and durability.

Stainless Steel: Offers corrosion resistance for medical and cleanroom environments.

Polymer Cages: Lightweight, reducing friction and noise.

Key Factors in Choosing Ball Bearing Linear Systems

Load Capacity – Must handle expected forces.

Speed – High-speed systems require low-friction designs.

Environment – Dust, moisture, or chemicals may affect performance.

Maintenance – Some systems require frequent lubrication, others are sealed.

Installation of Ball Bearing Linear Systems

Installation must be precise:

Rails should be perfectly aligned.

Carriages must be mounted securely.

Avoid contamination during setup.

Even small errors can reduce performance and shorten lifespan.

Lubrication and Maintenance

Lubrication ensures optimal performance:

Grease: Long-term, suitable for most applications.

Oil: Preferred for high-speed motion.

Self-lubricating options: Useful where access is limited.

Maintenance includes regular inspections, cleaning, and relubrication.

Signs of Wear in Ball Bearing Linear Systems

Grinding or squeaking noises.

Increased vibration during operation.

Decreased positional accuracy.

Visible wear marks on rails or carriages.

Troubleshooting Common Issues

Noise: Check lubrication and contamination.

Sticking: Verify alignment and clean rails.

Reduced accuracy: Replace worn components.

Cost of Ball Bearing Linear Systems

Prices depend on size, precision, and brand:

Entry-level models: $20–$100.

Mid-range systems: $100–$500.

High-end industrial systems: $500–$2000+.

While expensive, they reduce long-term downtime costs.

Top Manufacturers

THK (Japan)

Hiwin (Taiwan)

NSK (Japan)

Bosch Rexroth (Germany)

SKF (Sweden)

Innovations in Ball Bearing Linear Technology

Smart Sensors: Real-time wear monitoring.

Advanced Coatings: Reduce corrosion and friction.

Lightweight Materials: For faster motion and energy savings.

Future of Ball Bearing Linear Systems

The future is defined by:

IoT-enabled predictive maintenance.

AI-driven alignment monitoring.

Sustainable, recyclable materials.

Environmental Impact

Ball bearing linear systems save energy by reducing motor loads. Manufacturers are increasingly adopting eco-friendly lubricants and recyclable materials to align with green manufacturing practices.

FAQs

What is a ball bearing linear guide?

It’s a system that uses recirculating steel balls to provide smooth, precise motion along a rail.

Do ball bearing linear guides need lubrication?

Yes, lubrication is essential to prevent wear and ensure smooth motion.

Can they handle heavy loads?

Yes, especially roller-enhanced ball bearing linear systems.

Are they better than plain bearings?

They offer higher precision but cost more and require cleaner environments.

What industries use them?

CNC machining, robotics, automation, and medical devices.

How long do they last?

With proper care, they can last several years under continuous use.

Conclusion

The ball bearing linear system is a cornerstone of precision motion in modern industry. Offering smooth travel, low friction, and high load capacity, these systems are used in everything from 3D printers to surgical robots.

With innovations like smart sensors and eco-friendly materials, ball bearing linear guides are poised to become even more efficient, sustainable, and vital for the future of automation. Investing in high-quality ball bearing linear systems ensures not only accuracy but also long-term cost savings and reliability.

Suggested Inbound Links

CNC machining guide

Robotics automation systems

3D printing technology