Outline for “Linear Bearings and Rails”

| Section | Sub-Sections |

|---|---|

| Introduction | Importance of linear motion systems |

| Linear Bearings and Rails | Overview and definitions |

| Types of Linear Bearings | Ball bearings, roller bearings, plain bearings |

| Types of Linear Rails | Profiled rails, round rails, miniature rails |

| How Linear Bearings Work | The mechanics behind precision motion |

| Materials Used in Linear Bearings and Rails | Stainless steel, carbon steel, ceramics, polymers |

| Key Features of Linear Bearings | Load capacity, rigidity, low friction |

| Advantages of Linear Bearings and Rails | Smoothness, durability, accuracy |

| Common Applications in Manufacturing | CNC machines, robotics, automation |

| Use in 3D Printing | High accuracy and repeatability |

| Role in Medical Equipment | Scanners, diagnostic tools, lab devices |

| Applications in Aerospace | Flight simulators, aircraft assembly |

| Industrial Automation Benefits | Speed, reduced downtime, cost-efficiency |

| Precision in Robotics | Collaborative robots, industrial arms |

| Installation Guidelines | Alignment, preload, lubrication |

| Maintenance Requirements | Cleaning, lubrication, replacement cycles |

| Choosing the Right Linear Bearings and Rails | Factors: speed, load, environment |

| Comparison with Other Motion Systems | Linear guides vs. bushings vs. slides |

| Innovations in Linear Motion Technology | Smart sensors, self-lubricating designs |

| Cost Considerations | Budget vs. premium solutions |

| Common Problems and Troubleshooting | Noise, wear, misalignment |

| Best Brands and Manufacturers | Industry leaders and reliable suppliers |

| Future Trends in Linear Bearings and Rails | Automation, IoT integration |

| FAQs | Expert answers to common queries |

| Conclusion | Final insights |

Introduction

In the modern industrial world, motion must be precise, smooth, and reliable. That’s where linear bearings and rails step in. They are the unsung heroes behind machines that shape, print, scan, and even save lives. From robots assembling cars to medical devices scanning patients, these systems deliver unmatched accuracy and efficiency. Without them, automation as we know it would come to a grinding halt.

Let’s dive deep into the mechanics, applications, and benefits of linear bearings and rails while uncovering expert tips to maximize their performance.

Linear Bearings and Rails

Linear bearings and rails are mechanical components designed to provide free, controlled, and precise motion along a straight path. The bearing allows for frictionless movement, while the rail provides a guiding track. Together, they form the backbone of many motion systems in industries such as automation, manufacturing, robotics, and medical equipment.

They are like the tracks and wheels of a train—without the tracks, wheels can’t move straight, and without wheels, the tracks serve no purpose. This perfect harmony ensures accuracy in operations where even a small misalignment can cause costly errors.

Types of Linear Bearings

Ball Bearings

Ball-type linear bearings use rolling elements that circulate within the bearing housing, minimizing friction and enabling high-speed movement. They are best suited for applications requiring smoothness and low resistance.

Roller Bearings

Unlike balls, rollers distribute load across a larger area. This allows them to handle higher weight capacities, making them ideal for heavy-duty applications like large CNC machines and industrial automation systems.

Plain Bearings

Also known as bushings, plain bearings don’t use rolling elements. Instead, they rely on sliding surfaces, making them more resistant to dirt and contamination. They are often used in rugged environments.

Types of Linear Rails

Profiled Rails

These feature a flat track with grooves that match the bearing shape, allowing higher load capacities and rigidity. They are common in CNC machining centers.

Round Rails

Round rails are cylindrical and easier to install, though they are less rigid compared to profiled rails. They are excellent for light-to-medium applications.

Miniature Rails

These are smaller versions used in compact machines like 3D printers, laboratory devices, and portable automation equipment.

How Linear Bearings Work

Linear bearings work on the principle of rolling or sliding contact. In ball and roller bearings, the rolling elements circulate between the carriage and the rail, drastically reducing friction. In plain bearings, sliding contact occurs between surfaces, often enhanced with lubrication. This mechanism ensures controlled movement along the rail while maintaining alignment and precision.

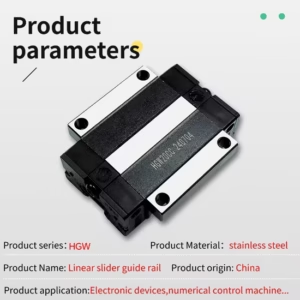

Materials Used in Linear Bearings and Rails

Stainless Steel – Resistant to corrosion, ideal for clean environments like medical and food industries.

Carbon Steel – Strong and affordable, suitable for general industrial use.

Ceramics – Lightweight, heat-resistant, and non-magnetic, used in specialized environments.

Polymers – Cost-effective, corrosion-resistant, and maintenance-free options for light-duty applications.

Key Features of Linear Bearings

High load capacity

Smooth and frictionless operation

Excellent rigidity and stability

Easy installation and maintenance

Compatibility with automation systems

Advantages of Linear Bearings and Rails

Precision in repetitive tasks

Longer service life with minimal wear

Reduced downtime in industrial machines

High speed and efficiency

Flexibility across multiple industries

Common Applications in Manufacturing

Factories heavily rely on linear bearings and rails for:

CNC machining centers

Packaging lines

Injection molding machines

Welding and assembly automation

These systems guarantee consistent results in mass production.

Use in 3D Printing

3D printers demand high precision to layer materials accurately. Linear bearings and rails provide smooth, repeatable motion for X, Y, and Z axes, ensuring high-quality prints without misalignment.

Role in Medical Equipment

Medical imaging devices, diagnostic machines, and robotic surgical tools depend on linear bearings and rails for precise positioning. In this sector, reliability isn’t just important—it’s life-saving.

Applications in Aerospace

From flight simulators to assembly lines of aircraft components, aerospace engineers use linear bearings and rails to maintain accuracy and safety.

Industrial Automation Benefits

Automation thrives on speed and reliability. Linear bearings allow robotic systems to perform repetitive tasks with minimal wear and tear, ensuring high productivity and cost savings.

Precision in Robotics

Robotic arms require controlled linear motion to handle delicate tasks. Bearings and rails help them maintain repeatability, accuracy, and flexibility across industries.

Installation Guidelines

Ensure rail alignment to avoid uneven wear.

Apply correct preload to balance load distribution.

Use proper lubrication to reduce friction.

Regularly check mounting bolts for security.

Maintenance Requirements

Regular maintenance extends the life of linear bearings and rails. Key practices include:

Cleaning rails from dust and debris

Re-lubricating bearings periodically

Inspecting for wear and cracks

Replacing damaged parts immediately

Choosing the Right Linear Bearings and Rails

When selecting, consider:

Load capacity

Operating speed

Environmental conditions (dust, moisture, temperature)

Precision requirements

Comparison with Other Motion Systems

Linear bearings and rails outperform alternatives like bushings and sliding guides in terms of smoothness, accuracy, and durability. However, they may require more precise installation and higher upfront costs.

Innovations in Linear Motion Technology

Recent developments include:

Self-lubricating rails

Smart bearings with IoT sensors

Lightweight composite materials

High-speed, low-noise designs

Cost Considerations

While premium linear bearings may seem costly upfront, they save money in the long run by reducing downtime, maintenance, and replacement frequency.

Common Problems and Troubleshooting

Noise – Often caused by poor lubrication.

Vibration – Usually due to misalignment.

Wear – Can result from dirt buildup or improper load distribution.

Best Brands and Manufacturers

Some globally trusted names include:

THK

NSK

Hiwin

SKF

Bosch Rexroth

Future Trends in Linear Bearings and Rails

The future points toward AI-driven predictive maintenance, smart sensors, and eco-friendly materials to reduce friction and energy usage.

FAQs

What are linear bearings and rails used for?

They are used to enable smooth, precise, and friction-free linear motion in machinery and automation systems.

How long do linear bearings last?

With proper maintenance, they can last for years, depending on load, speed, and operating conditions.

Do linear bearings need lubrication?

Yes, lubrication is essential to minimize wear and ensure smooth operation.

Can linear rails be cut to size?

Yes, most rails can be cut to fit custom applications.

Which industries use linear bearings the most?

Manufacturing, robotics, aerospace, automotive, and medical industries heavily rely on them.

Are plain bearings better than ball bearings?

Plain bearings perform better in dirty environments, while ball bearings excel in precision applications.

Conclusion

Linear bearings and rails form the backbone of precision motion across industries. Whether it’s the smooth movement of a 3D printer, the accuracy of a robotic arm, or the reliability of medical equipment, they keep the world moving—literally. Investing in the right system not only boosts performance but also ensures long-term cost efficiency and reliability.

Inbound Link Suggestions

Link to: CNC Machine Setup Guide

Link to: Robotics in Industrial Automation

Link to: Best Practices for Machine Maintenance