Outline for “Linear Rail and Bearings”

| Section | Subtopics |

|---|---|

| Introduction | The essential role of linear rails and bearings in modern motion systems |

| What Are Linear Rails and Bearings? | Definitions and distinctions |

| How Linear Rails and Bearings Work Together | Rolling motion and load distribution principles |

| Key Components of Linear Rail Systems | Rail, block, rolling elements, seals, lubrication |

| Design Features of YH Linear Systems | Engineering, geometry, and innovation |

| Types of Linear Rails and Bearings | Ball-type, roller-type, miniature, and heavy-duty |

| Material Selection and Surface Finishing | Metals, coatings, and treatments |

| Performance Characteristics | Rigidity, accuracy, and smoothness |

| Advantages of Linear Rail and Bearing Systems | Efficiency, life span, and low friction |

| Applications Across Industries | CNC, automation, robotics, and semiconductor equipment |

| YH Linear’s Engineering Standards | Precision manufacturing and inspection |

| Installation and Alignment Tips | Best practices for performance |

| Lubrication and Maintenance Guide | Extending operational lifespan |

| Common Issues and Solutions | Troubleshooting noise, wear, or misalignment |

| Comparing YH Linear with Competitors | Quality, customization, and cost efficiency |

| Sustainability and Eco-Friendly Manufacturing | Green materials and processes |

| Customization and OEM Support | Tailored solutions from YH Linear |

| The Future of Linear Rails and Bearings | Smart technologies and predictive maintenance |

| FAQs | Common customer questions |

| Conclusion | Recap and call to action |

| Inbound & Outbound Links | SEO link recommendations |

Linear Rail and Bearings

In the world of precision engineering, nothing defines accuracy and reliability more than the linear rail and bearings system. This combination forms the backbone of modern automation, CNC machinery, and robotics, enabling motion that is smooth, stable, and repeatable.

At YH Linear (https://yhlinear.com/), we specialize in manufacturing high-performance linear rails and bearings that transform the way machines move — offering precision that powers global industries.

What Are Linear Rails and Bearings?

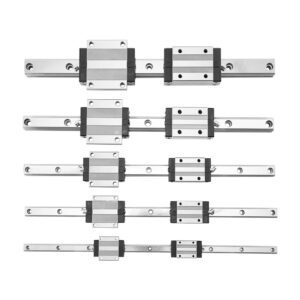

A linear rail provides a precisely machined path for motion, while linear bearings (or carriages) glide along that rail using rolling elements such as steel balls or rollers.

Together, they form a linear motion guide system, allowing machines to move objects along a straight path with minimal friction and maximum accuracy.

This innovation replaced traditional sliding mechanisms, offering longer lifespan, higher speed, and unmatched repeatability.

How Linear Rails and Bearings Work Together

Inside the bearing block, steel balls or rollers circulate continuously as the carriage moves. These rolling elements minimize surface contact, significantly reducing friction.

Each ball transfers the load between the rail and block while circulating back through internal channels. This ensures that motion remains smooth, stable, and precise — even under high-speed or high-load conditions.

The result is a system that combines efficiency, rigidity, and low wear, ideal for applications requiring micron-level accuracy.

Key Components of Linear Rail Systems

| Component | Function |

|---|---|

| Guide Rail | Provides the precision track for linear motion |

| Carriage (Block) | Moves along the rail carrying the load |

| Rolling Elements | Balls or rollers that circulate for smooth motion |

| Return System | Guides the rolling elements through continuous circulation |

| End Seals | Protect against dust, debris, and fluid contamination |

| Lubrication Port | Enables consistent and easy maintenance |

Each YH Linear component is CNC-machined and hardness-tested, ensuring consistent quality and dimensional accuracy.

Design Features of YH Linear Systems

Four-way equal load design for balanced rigidity

45° contact angle geometry for multidirectional load distribution

High carbon alloy steel rails for strength and longevity

Self-lubricating channels to minimize maintenance

Ultra-quiet ball circulation system for reduced vibration and noise

These features make YH Linear systems a preferred choice for high-precision and high-speed operations worldwide.

Types of Linear Rails and Bearings

Ball-Type Linear Guide: Designed for smooth and fast motion with minimal noise.

Roller-Type Linear Guide: Ideal for high rigidity and heavy loads.

Wide-Type Linear Rail: Provides higher stability against torque.

Miniature Linear Rail: Perfect for compact equipment in medical or semiconductor fields.

Heavy-Duty Linear Guide: Built for industrial-grade loads and large-scale machinery.

YH Linear offers each type in multiple accuracy grades to meet specific engineering needs.

Material Selection and Surface Finishing

At YH Linear, material selection is crucial for performance and lifespan:

SUJ2 Alloy Steel: Provides hardness and strength for high-load conditions.

SUS440C Stainless Steel: Offers corrosion resistance for cleanroom environments.

Nickel & Chrome Plating: Protects against rust and humidity.

Black Oxide Coating: Reduces friction and enhances appearance.

Every rail undergoes heat treatment, precision grinding, and polishing, ensuring consistency across production batches.

Performance Characteristics

High Rigidity: Four-point contact ensures strength under dynamic loads.

Low Friction: Rolling elements reduce drag compared to sliding surfaces.

Accuracy: Micron-level repeatability even during long-term use.

Speed: Supports rapid linear travel without sacrificing stability.

Durability: Long service life with minimal wear.

YH Linear systems combine performance and endurance for reliable, continuous operation.

Advantages of Linear Rail and Bearing Systems

Superior accuracy in positioning and motion control

Reduced friction for energy efficiency

Compact structure with high load-bearing capacity

Low maintenance requirements

Quiet and stable performance under all conditions

These systems form the foundation for precision in manufacturing and automation industries.

Applications Across Industries

YH Linear’s rails and bearings are widely used in:

CNC Machine Tools – Spindle and table movement

Robotics and Automation – Linear positioning and smooth motion

Semiconductor Manufacturing – Ultra-clean environments

Packaging Equipment – High-speed motion with accuracy

Medical Devices – Compact, silent motion mechanisms

Our products enable industrial excellence and mechanical precision across every application.

YH Linear’s Engineering Standards

Each YH Linear system is manufactured under ISO 9001-certified processes.

Our inspection standards ensure:

Dimensional accuracy within microns

High surface smoothness

Uniform preload tolerance

Stable motion performance

Our goal is simple — to provide reliable, world-class linear motion solutions.

Installation and Alignment Tips

Ensure flatness of mounting surfaces.

Align rails carefully using precision instruments.

Tighten bolts evenly to prevent stress deformation.

Lubricate rails before initial operation.

Run-in the system to verify smoothness and accuracy.

Proper installation ensures maximum performance and service life.

Lubrication and Maintenance Guide

Lubrication minimizes wear and noise while maximizing life:

Apply lithium or synthetic grease through built-in ports.

Reapply after 500–1000 hours depending on use.

Keep rails clean and dust-free.

Replace seals when contamination is visible.

YH Linear’s self-lubricating design helps extend maintenance intervals and reduce downtime.

Common Issues and Solutions

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Noise or vibration | Rail misalignment | Recalibrate rail positions |

| Rough movement | Contamination | Clean and relubricate |

| High friction | Low lubrication | Apply grease through port |

| Uneven wear | Overloading | Adjust system design |

Regular maintenance ensures smooth operation for years.

Comparing YH Linear with Competitors

| Feature | YH Linear | Other Brands |

|---|---|---|

| Precision Level | ±0.003 mm | ±0.01 mm |

| Noise Level | <50 dB | >60 dB |

| Load Capacity | High | Medium |

| Surface Finish | Mirror-grade | Standard |

| Custom Options | Full OEM support | Limited |

YH Linear stands out for customization, superior finish, and long-term reliability.

Sustainability and Eco-Friendly Manufacturing

YH Linear implements green production processes, using:

Recyclable materials

Low-emission plating technologies

Eco-safe lubricants

This approach reduces environmental impact while maintaining product quality.

Customization and OEM Support

YH Linear offers custom-engineered linear rails and bearings for OEMs, including:

Tailored preload and tolerance levels

Unique dimensions and coatings

Co-branded product labeling

Global delivery and technical support

We partner with industries to optimize performance and cost efficiency.

The Future of Linear Rails and Bearings

YH Linear is leading innovation through:

Smart sensors for real-time monitoring

Predictive maintenance algorithms

AI-integrated motion control systems

Lightweight, high-strength materials

The future of precision linear motion is intelligent — and YH Linear is at its forefront.

Frequently Asked Questions

What is the purpose of linear rails and bearings?

They provide smooth, precise linear motion in automated and CNC systems.

How long do YH Linear rails last?

With proper lubrication, they can last over 50,000 km of travel.

Can I request a custom size?

Yes, YH Linear offers full OEM customization options.

Are these rails suitable for cleanrooms?

Yes, stainless steel and anti-corrosion models are ideal for clean environments.

Do they require frequent maintenance?

No, thanks to YH Linear’s self-lubricating designs, maintenance is minimal.

Where can I purchase them?

Visit https://yhlinear.com/ for product details and quotes.

Conclusion

The linear rail and bearings system is the foundation of modern mechanical precision — enabling motion that is accurate, efficient, and reliable.

At YH Linear, we’ve dedicated ourselves to mastering this technology, providing customized solutions that support industries across the globe.

From CNC machining to robotics, YH Linear ensures your systems move with accuracy, last with durability, and perform with excellence.

👉 Explore our complete range at https://yhlinear.com/.

Suggested Inbound and Outbound Links

Inbound Links (YH Linear site):

Outbound Links: