Outline for “Linear Rail Slides”

| Section | Subtopics |

|---|---|

| Introduction | Overview of linear rail slides in precision machinery |

| What Are Linear Rail Slides? | Definition and working principle |

| Core Design and Functionality | Rail, carriage, and rolling mechanism |

| How Linear Rail Slides Operate | Load transfer and motion control |

| Engineering Innovations by YH Linear | Technology and production excellence |

| Key Materials and Finishes | Steel grades, coatings, and durability |

| Essential Features of YH Linear Rail Slides | Rigidity, smoothness, and accuracy |

| Major Benefits of Linear Rail Slides | Efficiency, reliability, and speed |

| Applications Across Industries | CNC, automation, robotics, and more |

| Comparison: Linear Rail Slides vs Traditional Systems | Friction, maintenance, lifespan |

| Types of Linear Rail Slides | Ball-type, roller-type, miniature, and heavy-duty |

| YH Linear’s Precision Manufacturing Process | CNC machining, heat treatment, and inspection |

| Installation and Calibration Best Practices | Step-by-step alignment guide |

| Lubrication and Preventive Maintenance | Extending service life |

| Common Problems and Fixes | Troubleshooting performance issues |

| Customization and OEM Services | Tailored solutions for every industry |

| YH Linear’s Quality and Certifications | ISO standards and product reliability |

| Sustainability in Production | Green materials and eco-safe coatings |

| The Future of Linear Rail Slides | Smart technologies and innovation trends |

| FAQs | Common questions and expert answers |

| Conclusion | Recap and call to action |

| Suggested Links | Inbound and outbound SEO links |

Linear Rail Slides

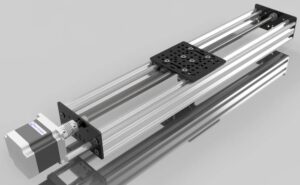

In today’s industrial world, linear rail slides are the unsung heroes of precision engineering. Whether in CNC machinery, robotics, semiconductor manufacturing, or medical automation, these systems deliver the smooth, accurate, and consistent motion that advanced technology demands.

At YH Linear (https://yhlinear.com/), we have perfected the art and science of linear motion—developing linear rail slides that blend cutting-edge engineering, superior materials, and reliable performance for all industries.

What Are Linear Rail Slides?

A linear rail slide is a motion component designed to provide precise, low-friction linear travel along a set path. It consists of a rail (the track) and a carriage or slider block that moves along it.

Inside the carriage are recirculating balls or rollers that reduce friction, allowing for smooth, stable, and accurate movement even under heavy loads.

This system has largely replaced traditional slide bearings due to its superior speed, longevity, and consistency—making it essential for precision motion systems worldwide.

Core Design and Functionality

The structure of a linear rail slide includes:

Guide Rail: A hardened, precision-ground track that supports motion.

Carriage (Block): The moving part that carries the load.

Rolling Elements: Balls or rollers that circulate within the block, minimizing friction.

End Caps and Seals: Prevent contamination from dust and debris.

Lubrication Ports: Maintain consistent lubrication to reduce wear.

Together, these components create a motion solution that is stable, accurate, and long-lasting.

How Linear Rail Slides Operate

Linear rail slides function based on the principle of rolling motion rather than sliding contact.

As the carriage moves along the rail, the balls or rollers circulate continuously within internal raceways, redistributing the load evenly across contact points.

This mechanism minimizes wear and reduces energy loss—allowing for quiet, smooth, and frictionless travel over long distances.

YH Linear’s proprietary designs ensure micron-level precision, even in demanding industrial environments.

Engineering Innovations by YH Linear

At YH Linear, innovation drives excellence. Our linear rail slides are manufactured with:

45° contact-angle geometry for multidirectional load handling

Four-way equal load design for rigidity and stability

Ultra-smooth ball circulation channels to minimize noise

High preload accuracy for vibration-free motion

Modular interchangeability for easy installation and replacement

Every unit undergoes automated quality inspection, ensuring consistent reliability across every piece.

Key Materials and Finishes

The quality of materials defines the longevity of a rail slide system. YH Linear uses:

SUJ2 High-Carbon Steel: For hardness and load strength

SUS440C Stainless Steel: For corrosion-resistant environments

Black Oxide Coating: For wear reduction and aesthetic protection

Chrome/Nickel Plating: To prevent rust and moisture damage

Every rail is heat-treated, precision-ground, and polished, achieving an ultra-smooth surface finish for consistent performance.

Essential Features of YH Linear Rail Slides

High rigidity with low deflection under load

Ultra-smooth motion with minimal friction

Low noise operation through optimized circulation

High accuracy repeatability up to ±0.003 mm

Durability for heavy-load applications

Compact, modular design for easy integration

These features ensure consistent performance and long-term reliability, even in challenging environments.

Major Benefits of Linear Rail Slides

Reduced energy loss through rolling motion

High-speed performance with stable accuracy

Long operational life with minimal maintenance

Excellent load-bearing capacity

Improved production efficiency in automation systems

Cost-effective operation over time

YH Linear’s rail slides are designed for efficiency, strength, and endurance—the pillars of modern industrial automation.

Applications Across Industries

YH Linear’s linear rail slides are indispensable in:

CNC Machines: Ensuring accurate cutting and positioning

Robotics: Enabling smooth and flexible arm movement

3D Printers: Providing stable linear motion paths

Semiconductor Equipment: Delivering micron-level precision

Medical Devices: Offering quiet, clean movement

Packaging and Automation Lines: Supporting continuous, high-speed motion

Each application benefits from YH Linear’s precision engineering and reliability.

Comparison: Linear Rail Slides vs Traditional Systems

| Feature | Linear Rail Slides | Traditional Sliding Rails |

|---|---|---|

| Friction | Very low | High |

| Accuracy | ±0.003 mm | ±0.02 mm |

| Noise Level | <50 dB | >65 dB |

| Maintenance | Minimal | Frequent |

| Speed Capability | High | Limited |

| Lifespan | Long | Short |

Linear rail slides outperform older systems in every measurable parameter, providing superior motion precision and endurance.

Types of Linear Rail Slides

Ball-Type Linear Slides – Smooth, quiet, ideal for light-to-medium loads.

Roller-Type Linear Slides – High rigidity for heavy-duty use.

Miniature Linear Slides – Compact designs for limited spaces.

Wide Linear Slides – Enhanced stability for complex motion.

Custom OEM Slides – Designed for specific industrial applications.

YH Linear provides fully customizable designs to suit every engineering requirement.

YH Linear’s Precision Manufacturing Process

Each YH Linear rail slide undergoes:

CNC Machining for dimensional accuracy

Heat Treatment for hardness and durability

Precision Grinding for smoothness

Assembly in a Clean Environment

Comprehensive Quality Testing

The result is a world-class linear motion product trusted by industries globally.

Installation and Calibration Best Practices

Ensure rail mounting surface flatness (≤0.02 mm deviation).

Align rails using high-precision tools.

Tighten bolts gradually in a cross-sequence pattern.

Lubricate rails before initial operation.

Test travel smoothness and adjust preload if needed.

Proper installation ensures maximal stability and product life.

Lubrication and Preventive Maintenance

To extend service life:

Use synthetic or lithium-based grease compatible with steel bearings.

Reapply lubrication every 500–1000 hours of operation.

Keep rails clean from dust and oil residues.

Replace seals if wear is visible.

YH Linear’s self-lubricating system helps extend intervals between maintenance cycles.

Common Problems and Fixes

| Problem | Cause | Solution |

|---|---|---|

| Uneven motion | Misalignment | Recalibrate rails |

| Noise or vibration | Lack of lubrication | Apply grease |

| Wear marks | Overload | Check capacity ratings |

| Contamination | Dust or debris | Clean and reseal system |

Regular care ensures long-lasting performance and reliability.

Customization and OEM Services

YH Linear offers full OEM and ODM support, including:

Customized dimensions and preload options

Special coatings for specific environments

Co-branded manufacturing for partners

Rapid prototype development

Our engineers collaborate closely with clients to deliver tailored motion solutions for unique applications.

YH Linear’s Quality and Certifications

YH Linear products comply with ISO 9001 and CE certifications, ensuring:

Micron-level accuracy verification

Rigidity and wear resistance testing

Vibration and noise measurement

100% inspection before delivery

Each rail slide is built to meet the highest international quality standards.

Sustainability in Production

YH Linear integrates sustainability through:

Use of recyclable materials

Eco-friendly plating and coating processes

Energy-efficient manufacturing systems

Waste reduction and recovery programs

We believe that precision and sustainability can coexist, building a greener future for industrial motion.

The Future of Linear Rail Slides

The future lies in smart motion systems—YH Linear is pioneering:

IoT-integrated slides for data monitoring

Predictive maintenance sensors

AI-based performance analysis

Lightweight, high-strength composite rails

Our focus remains on innovation that drives longer life, higher efficiency, and smarter control.

Frequently Asked Questions

What makes linear rail slides better than standard bearings?

They provide higher accuracy, lower friction, and longer lifespan.

Can I request a custom rail slide size?

Yes, YH Linear offers full OEM customization.

Are YH Linear products suitable for cleanrooms?

Yes, stainless steel versions are ideal for clean and sterile environments.

How long do YH Linear slides last?

With proper care, they can exceed 50,000 km of travel.

Where can I buy YH Linear slides?

Visit https://yhlinear.com/ to explore and order.

Conclusion

Linear rail slides are the foundation of motion precision — delivering the accuracy, stability, and endurance that modern automation requires.

At YH Linear, we merge engineering innovation, high-quality materials, and precision craftsmanship to create linear rail slides that redefine reliability in every application.

From CNC systems to robotics, YH Linear ensures every movement is flawless, durable, and precise.

Explore our full range of linear motion products today at https://yhlinear.com/.

Suggested Inbound and Outbound Links

Inbound Links (YH Linear site):

Outbound Links: