Linear rail slides are essential components in precision motion systems, used extensively in industries such as manufacturing, automation, robotics, and 3D printing. These systems rely on smooth and accurate linear movement to perform critical tasks. Linear rail slides combine linear rails and bearings to guide motion along a straight path with minimal friction, providing high precision and stability.

In this article, we will explore what linear rail slides are, how they function, the different types available, and their applications across various industries.

What is a Linear Rail Slide?

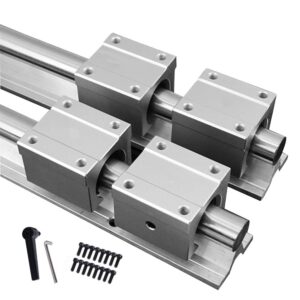

A linear rail slide is a mechanical assembly that consists of a linear rail and a bearing or slide unit that travels along the rail. The rail is typically mounted to a stationary frame, while the bearing or slide moves along it to provide smooth and accurate motion in a single direction. The assembly is designed to minimize friction, reduce wear, and provide precise movement over a long service life.

Key Components of a Linear Rail Slide

Linear Rail (Guide Rail): The rail is the base component that supports the bearing or carriage. It is often made from hardened steel or stainless steel to withstand wear and maintain stability.

Bearing or Slide Block (Carriage): The bearing or slide block is the moving part that rides on the rail. It contains rolling elements (like ball bearings or rollers) that reduce friction and enable smooth motion.

Lubrication System: Many linear rail slides come with built-in lubrication channels to reduce friction further and increase the system’s lifespan. Proper lubrication ensures smooth operation and minimizes wear.

End Caps/Seals: These are used to prevent contamination and protect the internal components of the bearing system.

How Do Linear Rail Slides Work?

Linear rail slides work by using rolling elements, such as ball bearings or cylindrical rollers, that move between the rail and the carriage. These rolling elements reduce friction, allowing for smooth, high-speed linear motion while maintaining precision.

Here’s a breakdown of the working mechanism:

Rolling Elements: The rolling elements in the bearing block roll along the rail’s surface, minimizing friction. This allows the slide block to move smoothly without the need for excessive force.

Rail Surface: The rail is precisely machined to ensure that the bearing travels along a straight path. The rail surface is typically hardened and coated to resist wear and maintain precision over time.

Load Distribution: The bearing is designed to distribute the load evenly across the rail, ensuring that the entire system remains stable even under heavy loads or during rapid movements.

Lubrication: To further reduce friction, many linear rail slides use grease or oil, either pre-applied or as part of the maintenance routine. This lubrication reduces wear on the moving parts and helps prevent overheating.

Types of Linear Rail Slides

There are several different types of linear rail slides, each suited to different applications based on factors like load capacity, speed, precision, and operating environment.

1. Ball Bearing Linear Slides (Ball Rail Guides)

Ball bearing linear slides are the most common type of linear rail slide. They feature a set of steel balls that move between the rail and the carriage. The ball bearings reduce friction significantly, allowing for smooth and high-speed motion with relatively light loads.

Advantages:

High-speed capability

Suitable for moderate loads

Low friction for smooth motion

Available in various sizes and configurations

Applications:

CNC machines

Automated assembly lines

3D printing

X-Y tables in laboratory equipment

2. Roller Bearing Linear Slides (Roller Rail Guides)

Roller bearing linear slides use cylindrical rollers instead of ball bearings. The larger surface area of rollers allows for greater load capacity compared to ball bearings, making them ideal for applications where higher loads are present.

Advantages:

Greater load capacity than ball bearings

Increased stability under high loads

Smooth and reliable motion

Applications:

Heavy-duty machinery

Conveying systems

Industrial robots

3. Crossed Roller Bearings

Crossed roller bearings are a more specialized type of linear rail slide. In this design, the rollers are arranged in a crisscross pattern, which enables the bearing to handle both radial and axial loads. This type of slide is used in applications requiring extremely high precision and rigidity.

Advantages:

Extremely high precision

Capable of handling both radial and axial loads

Excellent rigidity and stability

Applications:

Semiconductor manufacturing

Optical and laser equipment

Precision measuring instruments

4. Magnetic Linear Slides

Magnetic linear slides use magnetic forces to provide frictionless motion. The bearing block is levitated by magnets, eliminating contact with the rail and resulting in zero friction. This design is ideal for high-speed or high-precision applications where traditional bearings may struggle.

Advantages:

No physical contact between moving parts

Zero friction for high-speed motion

Extremely smooth operation with minimal wear

Applications:

High-precision industrial equipment

Clean rooms and vacuum environments

Research applications

5. Air Bearing Linear Slides

Air bearing slides function similarly to magnetic slides, but instead of magnets, they use a thin film of air to lift and guide the bearing along the rail. The air gap between the rail and the bearing results in completely frictionless motion, offering superior performance for precision applications.

Advantages:

Frictionless motion

Extremely high precision and accuracy

Ideal for high-speed applications

Applications:

Precision manufacturing

Optical alignment systems

Metrology and testing equipment

Benefits of Linear Rail Slides

Linear rail slides offer numerous advantages that make them essential in many precision motion systems:

1. High Precision and Accuracy

Linear rail slides are designed for extremely accurate motion. The rolling elements, such as ball bearings or rollers, ensure that the carriage remains aligned with the rail throughout its travel, preventing any wobble or misalignment. This precision is essential in applications like CNC machining, 3D printing, and robotics.

2. Smooth Motion and Reduced Friction

One of the key benefits of linear rail slides is the reduced friction between the moving parts. By using ball bearings or rollers, these systems allow for smooth motion with minimal resistance. This not only enhances the speed and efficiency of the system but also reduces the wear and tear on components.

3. Increased Load Capacity

Certain types of linear rail slides, such as those with roller bearings, are designed to handle heavier loads than traditional slides with ball bearings. This allows these systems to be used in applications where high loads are required, such as in large industrial machines and automated conveyors.

4. Durability and Longevity

Because linear rail slides are designed to minimize friction, they tend to experience less wear and tear compared to traditional sliding systems. With proper lubrication and maintenance, these systems can last for years, providing reliable and consistent performance even under demanding conditions.

5. Low Maintenance

Linear rail slides typically require less maintenance than traditional sliding systems. Many systems come pre-lubricated, and their sealed designs prevent dirt and contaminants from entering, reducing the frequency of maintenance needed. However, periodic lubrication and inspections are still important to ensure optimal performance.

Applications of Linear Rail Slides

Linear rail slides are used in a wide range of industries due to their ability to provide smooth, precise motion. Some of the key applications include:

1. CNC Machines

CNC machines rely on linear rail slides to guide the movement of the cutting tool or workpiece. The precise motion provided by the linear slide ensures that the cuts are accurate, and the system operates efficiently.

2. Robotics

Linear rail slides are commonly used in robotic arms to provide smooth, controlled motion. Whether used for assembly, packaging, or pick-and-place operations, these systems allow the robotic arms to move with high precision and repeatability.

3. 3D Printing

In 3D printers, linear rail slides guide the printhead and the print bed. The accuracy of the linear rail system ensures that the printed object is built layer by layer with precision, especially in high-resolution applications.

4. Automated Assembly Lines

In automation, linear rail slides are used to guide conveyors and robotic arms that move parts along an assembly line. Their ability to handle high loads and provide smooth motion increases efficiency and reduces operational downtime.

5. Medical Devices

Many medical devices, such as MRI machines, X-ray systems, and surgical robots, rely on linear rail slides to achieve precise movement. In these applications, maintaining accuracy and smooth motion is crucial to ensuring the safety and effectiveness of the equipment.

Conclusion

Linear rail slides are indispensable components in modern precision motion systems, providing smooth, accurate, and reliable motion in various applications. Whether used in CNC machines, robotics, or 3D printing, these systems enable high-speed, high-precision movements with minimal friction and wear.

By understanding the different types of linear rail slides, their benefits, and their applications, engineers and designers can make informed decisions to ensure optimal performance in their systems. With the right selection and maintenance, linear rail slides can provide long-lasting, efficient motion that meets the demands of modern manufacturing, robotics, and automation.