Compact, efficient, and remarkably accurate — the low profile linear rail has become a game-changer in modern automation and precision engineering. Designed for applications where space is limited but precision is non-negotiable, these rails deliver stable and smooth linear motion in smaller form factors. Whether it’s a semiconductor device, a medical robot, or a miniature CNC system, low profile linear rails are the invisible foundation of accuracy.

In this comprehensive guide, we’ll explore what makes these rails unique, how they work, their applications, and why they’re the top choice for industries aiming for high precision in limited spaces.

Outline

| Headings and Subheadings | Description |

|---|---|

| Introduction to Low Profile Linear Rail | Overview and importance in engineering |

| What Is a Low Profile Linear Rail? | Definition and characteristics |

| The Rise of Compact Linear Motion Systems | Evolution of miniature rail design |

| Key Components of a Low Profile Linear Rail | Explaining rail, carriage, and bearing setup |

| How Does a Low Profile Linear Rail Work? | Working mechanism and motion dynamics |

| Design Advantages of a Low Profile Linear Rail | Space efficiency and structural benefits |

| Materials Used in Construction | Common materials and finishes |

| Performance and Load Capacity | Strength and limitations |

| Comparison: Low Profile vs Standard Linear Rail | Differences in size, rigidity, and use |

| Types of Low Profile Linear Rails | Classification by shape and function |

| Installation Techniques for Low Profile Rails | Best practices for mounting and alignment |

| Common Mistakes During Installation | Errors that affect precision |

| Lubrication and Maintenance Practices | How to extend service life |

| Applications in CNC and Automation | Use in manufacturing environments |

| Role in Robotics and Medical Devices | Precision applications in compact systems |

| Integration in 3D Printing and Electronics | Lightweight motion systems for accuracy |

| Cost Considerations and Value Analysis | Price vs performance insights |

| Top Brands Offering Low Profile Rails | Leading manufacturers worldwide |

| Troubleshooting and Performance Optimization | Fixing vibration and accuracy issues |

| Environmental Resistance and Coatings | Enhancing corrosion and wear protection |

| Durability and Lifespan | What impacts longevity |

| Safety Measures and Handling Tips | Proper care and installation safety |

| Future Trends in Linear Motion Design | Smart compact motion technology |

| Why Engineers Prefer Low Profile Linear Rails | Real-world benefits and feedback |

| FAQs | Common questions and answers |

| Final Thoughts on Low Profile Linear Rail | Summary and closing insights |

Introduction to Low Profile Linear Rail

The low profile linear rail represents a cutting-edge evolution in motion control engineering. It delivers the precision of traditional linear rails but in a slimmer, space-saving form. By minimizing height without sacrificing strength, these rails are essential in devices that require compact layouts — from precision medical scanners to compact industrial robots.

With technology shrinking and automation advancing, the demand for low profile linear rails has skyrocketed. Their seamless integration into tight spaces makes them ideal for modern machine design.

What Is a Low Profile Linear Rail?

A low profile linear rail is a precision-guiding component designed for smooth linear movement where installation space is limited. Its defining feature is its reduced height, allowing for compact machine architecture without compromising on accuracy or load capacity.

Despite their smaller size, these rails maintain impressive rigidity and performance, making them indispensable in lightweight and high-speed motion applications.

The Rise of Compact Linear Motion Systems

As industries push for miniaturization and higher efficiency, traditional bulky motion systems no longer fit the bill. The shift toward compact automation, portable robotics, and medical instruments created the need for low profile linear rails that could provide the same — or even better — accuracy in less space.

These innovations mark a milestone in mechanical design, merging precision engineering with ergonomic, compact design principles.

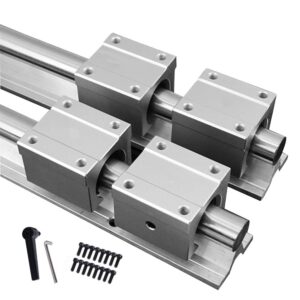

Key Components of a Low Profile Linear Rail

A typical low profile linear rail assembly includes:

Precision-ground rail: The base structure providing the linear path.

Carriage (slider or block): Houses rolling elements to reduce friction.

Rolling elements (balls or rollers): Enable smooth, frictionless motion.

End seals and scrapers: Protect internal components from debris.

Mounting holes: Allow easy installation on machine frames.

Each element contributes to delivering the stability, accuracy, and repeatability required for modern motion systems.

How Does a Low Profile Linear Rail Work?

The working mechanism is based on rolling motion rather than sliding contact. The rail features precisely machined grooves where recirculating ball bearings roll within the carriage block. This design minimizes friction, resulting in near-zero backlash and exceptional precision.

Because of its reduced height, the rail maintains a lower center of gravity — reducing vibration and increasing motion stability, even at high speeds.

Design Advantages of a Low Profile Linear Rail

Here’s why these rails are revolutionizing precision motion:

Space efficiency: Ideal for compact machinery layouts.

Lightweight structure: Reduces system mass without affecting strength.

Enhanced stability: Lower center of gravity improves vibration resistance.

Simplified integration: Fits seamlessly into tight mechanical spaces.

Quiet operation: Optimized for smooth, silent motion.

The slim design also helps achieve sleek machine aesthetics — a growing priority in modern industrial design.

Materials Used in Construction

Most low profile linear rails are manufactured from hardened stainless steel or high-carbon alloy steel. Carriages often use aluminum alloy housings with precision-ground steel inserts.

Surface treatments such as nickel plating, black oxide coating, or hard chrome enhance corrosion resistance, making them suitable for demanding environments like cleanrooms or high-humidity zones.

Performance and Load Capacity

Despite their slim design, these rails offer impressive strength. Depending on design and material, a low profile linear rail can handle loads ranging from 500 N to over 8000 N.

They also provide high moment load resistance, making them reliable even in multi-axis motion setups or high-speed equipment.

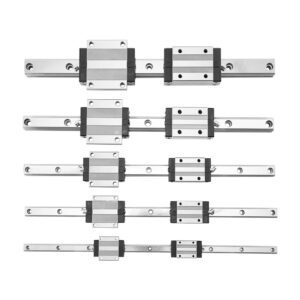

Comparison: Low Profile vs Standard Linear Rail

| Feature | Low Profile Linear Rail | Standard Linear Rail |

|---|---|---|

| Height | Reduced | Taller and bulkier |

| Load Capacity | Moderate to high | Very high |

| Rigidity | Excellent for compact systems | Superior for heavy-duty |

| Weight | Lightweight | Heavier |

| Installation Space | Minimal | Requires more clearance |

| Best Use | Compact and portable devices | Large industrial machinery |

This comparison highlights how low profile linear rails are ideal for modern designs where both space and accuracy are critical.

Types of Low Profile Linear Rails

Common types include:

Ball-type low profile rails: Offer ultra-smooth motion for precision systems.

Roller-type rails: Handle higher loads and provide better rigidity.

Miniature linear rails: Ultra-small versions for electronics and optical devices.

Self-lubricating rails: Include built-in lubrication systems for maintenance-free operation.

Each type is tailored to meet specific industrial or research needs.

Installation Techniques for Low Profile Rails

Proper installation ensures long-term reliability:

Prepare the base surface: It must be clean, level, and rigid.

Align the rail: Use dowel pins or precision jigs.

Tighten mounting bolts evenly: Avoid overtightening.

Install the carriage: Move it gently to ensure smooth travel.

Lubricate if required: Apply recommended grease or oil.

Correct alignment minimizes vibration and maximizes rail life.

Common Mistakes During Installation

Avoid these common errors:

Uneven mounting surfaces.

Using incorrect torque on bolts.

Ignoring preload adjustments.

Contaminated or dry bearings.

Such mistakes can cause excessive wear, noise, or reduced accuracy over time.

Lubrication and Maintenance Practices

Lubrication is essential for maintaining smooth motion. Many modern low profile linear rails feature integrated lubrication systems that continuously distribute oil or grease through internal channels.

Regular maintenance includes cleaning debris, checking for alignment, and inspecting seals for wear. When maintained properly, these rails can last for millions of cycles.

Applications in CNC and Automation

In CNC machines, low profile linear rails are used for axes that require precision in limited vertical space, such as laser engraving systems, pick-and-place machines, and miniature routers.

Their compact nature allows engineers to optimize designs without sacrificing stability or precision.

Role in Robotics and Medical Devices

Robots often use low profile rails in joints, sliders, and actuators to achieve compact, smooth, and accurate movements. Medical imaging devices, surgical robots, and laboratory automation systems also benefit from their silent operation and corrosion-resistant materials.

Integration in 3D Printing and Electronics

3D printers and PCB assembly machines rely on low profile linear rails to maintain positional accuracy at high speeds. Their low vibration characteristics ensure precise layer deposition and alignment — vital for achieving top-tier print quality or electronic assembly precision.

Cost Considerations and Value Analysis

While low profile linear rails can cost more per unit length than standard rails due to precision manufacturing, the value they offer in compactness, accuracy, and durability far outweighs the cost.

For space-constrained designs, they reduce the need for bulky structures — cutting down overall project costs.

Top Brands Offering Low Profile Rails

Leading manufacturers include:

THK

Hiwin

NSK

IKO

Misumi

Bosch Rexroth

These brands are known for high precision, long life, and compatibility across multiple applications.

Troubleshooting and Performance Optimization

| Issue | Possible Cause | Solution |

|---|---|---|

| Vibration or noise | Misalignment or lack of lubrication | Realign and relubricate |

| Uneven motion | Contaminated rail or worn balls | Clean and inspect |

| Reduced precision | Improper mounting surface | Re-machine or shim base |

| Corrosion | Poor coating or moisture exposure | Use stainless or coated variants |

Routine inspection prevents downtime and ensures consistent motion performance.

Environmental Resistance and Coatings

For harsh conditions, rails come with anti-corrosion coatings such as nickel or zinc. In cleanroom or vacuum applications, dry lubrication systems eliminate contamination risks, ensuring silent, dust-free performance.

Durability and Lifespan

With proper care, low profile linear rails can last for tens of millions of cycles. Durability depends on factors such as lubrication frequency, load distribution, and operating environment.

Safety Measures and Handling Tips

Always handle rails with care to avoid dents or contamination. During installation, wear gloves and store unused rails in a dry, clean area. Avoid dropping or applying impact forces, as this can deform the precision-ground surface.

Future Trends in Linear Motion Design

The future is bright for low profile linear rails. Innovations like smart sensors, self-monitoring lubrication, and composite material rails are transforming how motion systems operate. These advancements will make compact, intelligent, and maintenance-free systems the new industrial standard.

Why Engineers Prefer Low Profile Linear Rails

Engineers love low profile linear rails because they offer a perfect trifecta: space efficiency, performance, and precision. Their lightweight design reduces overall machine mass, their smooth motion enhances accuracy, and their reliability ensures low downtime — all key in competitive industries.

FAQs

What makes a linear rail “low profile”?

Its reduced height and compact design allow it to fit in tight spaces without compromising precision.

Are low profile linear rails strong enough for heavy-duty use?

Yes, supported variants can handle substantial loads depending on material and design.

Do they require frequent lubrication?

Not necessarily — many modern rails include self-lubricating systems for long-term use.

Can I cut a low profile rail to length?

Yes, but it should be done with precision cutting tools to avoid damaging the bearing tracks.

What is the lifespan of a low profile linear rail?

With proper maintenance, they can last over 10 million cycles or several years of continuous operation.

Where are low profile rails commonly used?

They’re widely used in CNC systems, robotics, automation, 3D printing, and medical devices.