Outline for “Linear Bearing Rail System”

| Section | Subtopics |

|---|---|

| Introduction | Overview and importance of linear bearing rail systems |

| What Is a Linear Bearing Rail System? | Structure and working principle |

| How Linear Bearing Rail Systems Work | Rolling motion and load distribution |

| Main Components of a Linear Bearing Rail System | Rail, bearing block, balls/rollers, seals |

| YH Linear’s Precision Engineering Advantage | Technology and design excellence |

| Key Features and Benefits | Accuracy, rigidity, and noise reduction |

| Material and Surface Treatment | Steel, stainless, and coating technologies |

| Applications of Linear Bearing Rail Systems | CNC, automation, robotics, and transport |

| Difference Between Linear Rail and Bearing System | Comparative overview |

| Design Variants Offered by YH Linear | Ball type, roller type, and heavy-duty models |

| Installation and Alignment Guidelines | Steps for perfect precision setup |

| Lubrication and Maintenance | Ensuring longevity and smooth operation |

| Troubleshooting Common Issues | Noise, friction, and wear solutions |

| YH Linear’s Quality and Inspection Process | Testing and certifications |

| Heavy Load Linear Rail Systems | Engineering for industrial performance |

| Customization and OEM Capabilities | Tailor-made solutions for clients |

| Eco-Friendly Manufacturing Approach | Sustainability at YH Linear |

| Future Trends in Linear Bearing Systems | Smart sensors and AI maintenance |

| FAQs | Commonly asked questions |

| Conclusion | Final thoughts and call to action |

| Suggested SEO Links | Internal and external link suggestions |

Linear Bearing Rail System

In the realm of industrial automation and CNC precision, the linear bearing rail system plays a vital role.

It is the invisible yet indispensable backbone that ensures smooth, accurate, and repeatable linear motion across thousands of industrial machines.

At YH Linear (https://yhlinear.com/), we have engineered linear bearing rail systems that combine high rigidity, precision, and long-lasting reliability, making them the preferred choice of global manufacturers.

What Is a Linear Bearing Rail System?

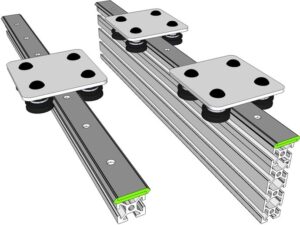

A linear bearing rail system is a mechanical assembly designed to support and guide motion along a straight line with minimal friction.

It typically consists of a hardened guide rail and a bearing block that houses rolling elements such as steel balls or rollers.

This system allows components or machine parts to move precisely under heavy loads, ensuring both accuracy and stability.

How Linear Bearing Rail Systems Work

The working principle is elegantly simple yet technologically advanced.

The bearing block moves along the hardened rail, supported by circulating rolling elements that reduce friction to near zero.

This design ensures:

Smooth linear travel without stick-slip motion

Even load distribution across the rail length

Minimal wear and noise

High-speed, vibration-free movement

At YH Linear, every rail system is designed for consistent performance and endurance, even under continuous industrial operation.

Main Components of a Linear Bearing Rail System

| Component | Function |

|---|---|

| Guide Rail | Provides the track for linear motion and alignment |

| Bearing Block (Carriage) | Supports the load and ensures motion smoothness |

| Rolling Elements (Balls/Rollers) | Reduce friction and maintain precision |

| End Caps and Seals | Protect against dust and retain lubrication |

| Lubrication Ports | Ensure long-term smooth operation |

Each YH Linear component is precision-machined and hardened for exceptional performance in demanding environments.

YH Linear’s Precision Engineering Advantage

At YH Linear, precision is not optional — it’s a promise.

We utilize advanced CNC machining, surface grinding, and automated inspection systems to ensure every rail system meets exact tolerances.

Our engineering advantages include:

45° contact-angle design for multi-directional load capacity

Optimized ball circulation channels for smoother movement

Zero-clearance preload system for rigidity

Noise-reducing end cap design

These innovations position YH Linear as a leader in precision linear motion systems.

Key Features and Benefits

Exceptional Accuracy: Enables micron-level motion repeatability.

High Rigidity: Handles both vertical and horizontal forces effectively.

Reduced Friction: Ensures longer life and smoother motion.

Low Noise Operation: Perfect for cleanroom and automation use.

Corrosion Resistance: Coatings prevent rust and wear.

Easy Installation: Interchangeable with global standards.

Every YH Linear rail system is built to deliver high performance under pressure.

Material and Surface Treatment

YH Linear uses materials chosen for durability and precision:

High-Carbon Alloy Steel (SUJ2): Ensures hardness and fatigue strength.

SUS440C Stainless Steel: Ideal for corrosive and cleanroom environments.

Chromium or Nickel Coatings: Provide superior rust resistance.

Black Oxide Finish: Enhances protection and reduces glare.

Each surface is superfinished and heat-treated, ensuring smooth, long-lasting performance.

Applications of Linear Bearing Rail Systems

These systems power the movement in industries that demand precision, speed, and reliability:

CNC machining centers

Laser cutting and engraving equipment

Robotics and automation lines

Medical devices

Semiconductor manufacturing

Packaging and logistics machinery

YH Linear’s systems perform flawlessly even in high-vibration, high-load environments.

Difference Between Linear Rail and Bearing System

| Feature | Linear Bearing Rail System | Standard Linear Rail |

|---|---|---|

| Friction | Ultra-low (rolling contact) | Moderate |

| Load Capacity | High | Medium |

| Rigidity | Excellent | Average |

| Lifespan | Long | Shorter |

| Maintenance | Low | Frequent |

YH Linear’s integrated bearing rail systems offer the perfect balance between strength, accuracy, and efficiency.

Design Variants Offered by YH Linear

Ball-Type Linear Rail Systems – For high-speed and low-friction motion.

Roller-Type Linear Rails – For higher load capacity and rigidity.

Heavy-Duty Linear Bearing Rails – For demanding industrial machinery.

Miniature Guide Rails – Compact design for electronics and medical use.

YH Linear ensures each system fits your specific motion requirements.

Installation and Alignment Guidelines

For best results:

Ensure flat mounting surfaces within ±0.02 mm.

Tighten bolts gradually in cross patterns.

Use precision alignment tools.

Lubricate before operation.

Test motion for smoothness.

Following YH Linear’s installation standards maximizes accuracy and service life.

Lubrication and Maintenance

Lubrication keeps your linear rail running silently and efficiently.

YH Linear recommends:

Lithium grease for standard environments.

Special cleanroom oil for contamination-free use.

Lubrication every 1000–2000 operating hours.

Optional self-lubricating systems further reduce maintenance needs.

Troubleshooting Common Issues

| Problem | Cause | Solution |

|---|---|---|

| Vibration or noise | Misalignment | Reinstall and re-lubricate |

| Uneven motion | Contamination | Clean and check seals |

| Excess wear | Overload | Adjust load or switch to roller type |

| Rust formation | Moisture | Use coated or stainless rails |

Routine inspection ensures long-term, trouble-free operation.

YH Linear’s Quality and Inspection Process

Every rail system undergoes:

CMM dimensional inspection

Noise and vibration testing

Load endurance trials

Hardness and surface roughness testing

These rigorous checks ensure that each product meets international performance standards.

Heavy Load Linear Rail Systems

For high-force environments, YH Linear provides heavy-duty linear bearing rail systems capable of withstanding extreme pressures and continuous use.

They are ideal for automotive, aerospace, and precision machining applications where performance and reliability cannot be compromised.

Customization and OEM Capabilities

YH Linear offers complete customization and OEM manufacturing:

Custom lengths, hole spacing, and mounting patterns

Unique coatings or materials

Special preload and accuracy grades

Co-branded OEM solutions

Our team ensures every project aligns perfectly with your system requirements.

Eco-Friendly Manufacturing Approach

YH Linear integrates sustainability across its processes:

Energy-efficient machining systems

Recyclable materials

Waste oil filtration and recycling

Eco-friendly coating technology

Our goal: precision without pollution.

Future Trends in Linear Bearing Systems

The next generation of rail systems will feature:

Smart sensors for predictive maintenance

AI-based performance analysis

Composite materials for lightweight designs

Self-lubricating polymer liners

YH Linear continues to lead this evolution through research and innovation.

FAQs

What is a linear bearing rail system used for?

It’s used to provide smooth, frictionless linear motion in industrial machines and automation systems.

Do YH Linear rails fit other global brands?

Yes — they follow international dimension standards.

How long do they last?

With proper lubrication, YH Linear rails can last over 10 years of continuous use.

Can I use them in cleanrooms?

Yes, stainless and low-particle versions are available.

Where can I buy YH Linear products?

Visit https://yhlinear.com/ to contact our sales team or local distributors.

Conclusion

The linear bearing rail system is the foundation of precision motion — and YH Linear stands at the forefront of this technology.

Our systems deliver unrivaled smoothness, durability, and precision, making them the trusted choice for global automation and CNC industries.

For your next motion control project, choose YH Linear — your partner in engineering excellence.

👉 Learn more at https://yhlinear.com/

Suggested SEO Links

Inbound Links (YH Linear site):

Outbound Links: