Outline for “Linear Guide Rail System”

| Section | Subtopics |

|---|---|

| Introduction | Why linear guide rail systems are crucial in modern industry |

| Understanding the Linear Guide Rail System | Definition and operating principles |

| Key Components of a Linear Guide Rail System | Rails, blocks, rolling elements, seals |

| How Linear Guide Rail Systems Work | Mechanics of linear motion |

| Design and Engineering of YH Linear Systems | Precision manufacturing and innovation |

| Material Quality and Surface Treatment | Corrosion resistance and longevity |

| Features of YH Linear Guide Rail Systems | Rigidity, load capacity, accuracy |

| Advantages of Linear Guide Rail Systems | Efficiency, reliability, lifespan |

| Applications in Different Industries | CNC, robotics, automation, medical, logistics |

| YH Linear Product Range Overview | Various models and specifications |

| Comparison: Linear Guide Rail vs Traditional Sliding Rails | Performance and efficiency differences |

| Installation Guidelines | Alignment and torque recommendations |

| Lubrication and Maintenance | Extending life and preventing wear |

| Common Issues and Troubleshooting | Noise, wear, or alignment errors |

| Customization Options at YH Linear | Tailor-made solutions for different environments |

| Certifications and Quality Control | ISO, CE, and testing standards |

| Environmental Sustainability in Production | Eco-friendly coatings and processes |

| The Future of Linear Guide Rail Systems | AI, IoT, and smart predictive technologies |

| FAQs | Addressing common user concerns |

| Conclusion | Recap and call to explore YH Linear systems |

| Inbound and Outbound Links | SEO link suggestions |

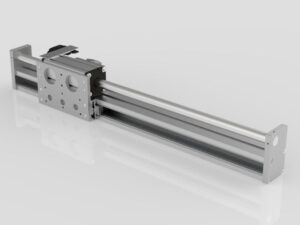

Linear Guide Rail System

Every motion system that demands precision and consistency relies on one critical component — the linear guide rail system. It ensures that machine components move in a straight line with minimal friction and maximum accuracy.

At YH Linear (https://yhlinear.com/), we have engineered our linear guide rail systems to deliver exceptional stability, precision, and reliability across a wide range of industrial applications — from CNC machines to advanced robotics and semiconductor automation.

Understanding the Linear Guide Rail System

A linear guide rail system is a mechanical assembly that enables linear motion using a rail and a carriage (or block) that moves along it with rolling elements.

Unlike traditional sliding systems that rely on surface contact, this setup uses rolling balls or cylindrical rollers to reduce friction, providing high-speed, low-resistance, and highly accurate movement.

This innovation revolutionized industrial automation by combining precision motion with durable load-bearing capacity.

Key Components of a Linear Guide Rail System

| Component | Description |

|---|---|

| Guide Rail | A hardened, precision-ground track providing linear motion paths. |

| Carriage (Block) | The moving component housing the rolling elements. |

| Rolling Elements (Balls/Rollers) | Enable smooth rolling and load transfer. |

| Return Cap System | Circulates the rolling elements inside the block. |

| End Seals and Scrapers | Protect against debris and contamination. |

| Lubrication Ports | Allow easy grease or oil injection to reduce wear. |

At YH Linear, every component undergoes micron-level grinding to ensure perfect alignment and uniform contact across all axes.

How Linear Guide Rail Systems Work

When motion begins, the carriage slides along the rail. Inside the block, balls or rollers circulate continuously in a loop, transferring load evenly across all contact points.

This recirculating mechanism minimizes wear and ensures consistent, smooth motion even under heavy loads.

The result? Silent, accurate, and maintenance-efficient linear travel ideal for both precision tools and automated manufacturing.

Design and Engineering of YH Linear Systems

YH Linear’s engineering philosophy focuses on balance between rigidity and motion smoothness.

Our systems feature:

Four-way equal load design (up, down, left, right) for multi-directional stability

45° contact angle geometry for optimized load distribution

High-strength alloy steel rails for enhanced durability

Micron-level precision grinding for uniformity and accuracy

Each YH Linear guide rail system is built using computerized quality inspection, ensuring zero tolerance for defects.

Material Quality and Surface Treatment

YH Linear uses premium materials to withstand extreme industrial environments:

SUJ2 Bearing Steel – High hardness and load capacity

SUS440C Stainless Steel – Corrosion-resistant for cleanroom or medical use

Nickel/Chrome Plating – Anti-rust protection

Black Oxide Coating – Minimizes friction and improves aesthetics

This attention to detail ensures that YH Linear’s rails remain smooth, durable, and accurate for years of continuous operation.

Features of YH Linear Guide Rail Systems

Exceptional Rigidity: Handles heavy static and dynamic loads.

Ultra-High Accuracy: Micron-level repeatability for precision machines.

Smooth Operation: Reduced vibration and noise through precision ball circulation.

Long Lifespan: Hardened rails and quality seals extend service life.

Compact and Modular: Easy integration into various systems.

Self-Lubrication Option: Reduced maintenance frequency.

Each YH Linear rail is engineered to provide performance you can trust, even in demanding environments.

Advantages of Linear Guide Rail Systems

Dramatically reduced friction and energy loss

Increased accuracy and speed response

High rigidity for load-bearing and torque resistance

Low maintenance cost due to smooth rolling motion

Long-term reliability even under continuous operation

In short, YH Linear systems represent the perfect balance between strength and precision.

Applications in Different Industries

YH Linear guide rail systems power a wide range of machines:

CNC Machining Centers – For high-precision positioning.

Robotics – For articulated arm and pick-and-place movement.

Semiconductor Equipment – For ultra-clean and precise motion.

Automated Production Lines – For efficient, repeatable processes.

Medical and Optical Equipment – For clean, silent linear travel.

These industries rely on YH Linear’s commitment to quality, stability, and innovation.

Comparison: Linear Guide Rail vs Traditional Sliding Rails

| Feature | Linear Guide Rail | Traditional Sliding Rail |

|---|---|---|

| Friction | Extremely low (rolling) | High (sliding) |

| Accuracy | Micron-level | Millimeter-level |

| Speed | High | Moderate |

| Rigidity | Excellent | Limited |

| Maintenance | Minimal | Frequent lubrication |

| Lifespan | Long | Short |

Linear guide rails offer superior performance in every key parameter, especially in industrial-grade motion systems.

Installation Guidelines

Prepare the mounting surface — ensure flatness within 0.02 mm.

Align both rails precisely to prevent parallelism errors.

Use a torque wrench to tighten bolts evenly.

Lubricate rails and blocks before initial operation.

Run test cycles to confirm smooth, silent travel.

Proper installation ensures optimal accuracy and bearing life.

Lubrication and Maintenance

To maintain top performance:

Use lithium or synthetic grease.

Re-lubricate every 500–1000 hours depending on conditions.

Wipe rails regularly to remove dust and debris.

Inspect preload and alignment periodically.

YH Linear rails are available with integrated lubrication ports for easy upkeep.

Common Issues and Troubleshooting

| Problem | Cause | Solution |

|---|---|---|

| Noise or vibration | Misalignment | Re-align and re-torque |

| Friction increase | Dry lubrication | Reapply grease |

| Debris contamination | Poor sealing | Replace end caps/seals |

| Uneven wear | Overload | Review system design |

Following YH Linear’s guidelines ensures consistent, error-free motion.

Customization Options at YH Linear

YH Linear provides custom-engineered guide rail systems, including:

Non-standard lengths or hole pitches

Custom preloads and accuracies

Stainless or coated finishes

High-speed or silent-motion versions

Our R&D team works directly with OEM clients to ensure perfect fit and performance.

Certifications and Quality Control

YH Linear products comply with:

ISO 9001 Quality Management System

CE Compliance

RoHS Environmental Standards

Each product is tested for precision, hardness, and smoothness to ensure it meets global standards.

Environmental Sustainability in Production

At YH Linear, sustainability is more than a trend — it’s a commitment.

We use eco-friendly lubricants, recyclable materials, and low-emission manufacturing processes to minimize environmental impact while maximizing performance.

The Future of Linear Guide Rail Systems

YH Linear is pioneering the next generation of guide rail systems with:

Smart sensors for predictive maintenance

AI-based vibration analysis

Self-lubricating polymers

Lightweight carbon composite rails

The future of precision motion is intelligent, sustainable, and YH Linear is leading the way.

Frequently Asked Questions

What is a linear guide rail system used for?

It provides smooth, accurate linear motion in machines like CNCs and robots.

What makes YH Linear’s guide rail systems unique?

High rigidity, precision design, and advanced surface treatments for longer life.

Can they operate at high speed?

Yes, YH Linear rails maintain accuracy even at high velocities.

Are they suitable for cleanroom use?

Yes, stainless steel and anti-corrosion models are ideal for clean environments.

What maintenance do they require?

Minimal — only periodic lubrication and cleaning.

Where can I buy YH Linear products?

Visit https://yhlinear.com/ for product catalogs and global distributors.

Conclusion

The linear guide rail system forms the backbone of precision motion in modern industry.

With decades of expertise and relentless innovation, YH Linear delivers guide rail systems that combine power, precision, and durability — ensuring your machines run smoother, longer, and more efficiently.

Discover the engineering excellence behind YH Linear at https://yhlinear.com/.

Suggested Inbound and Outbound Links

Inbound Links (YH Linear site):

Outbound Links: