Outline for “Guide Bearing”

| Main Topic | Subtopics |

|---|---|

| Introduction | Why guide bearings matter in motion systems |

| Guide Bearing | Definition and role in engineering |

| History of Bearings | From wooden rollers to precision bearings |

| Core Components | Rolling elements, races, housing |

| How Guide Bearings Work | Rolling contact principle |

| Types of Guide Bearings | Ball bearings, roller bearings, thrust, needle, tapered |

| Key Features | Load handling, accuracy, durability |

| Materials Used | Steel, stainless steel, ceramics, polymers |

| Guide Bearings in CNC Machines | Accuracy and tool stability |

| Applications in Robotics | Robotic arms, automation, cobots |

| Use in 3D Printing | Smooth layering and stability |

| Automotive Applications | Wheel hubs, transmissions, suspension |

| Aerospace Applications | High-speed and high-load systems |

| Benefits of Guide Bearings | Efficiency, smoothness, lifespan |

| Common Issues | Misalignment, wear, overheating |

| Maintenance Best Practices | Cleaning, lubrication, inspection |

| Choosing the Right Bearing | Factors: load, speed, environment |

| Bearings vs. Bushings | Key differences |

| DIY Applications | Hobby CNCs, 3D printers, camera rigs |

| Cost Considerations | Price ranges and influencing factors |

| Top Manufacturers | SKF, NSK, NTN, Timken |

| Industry-Specific Uses | Medical devices, packaging, electronics |

| Innovations in Guide Bearings | Self-lubrication, hybrid ceramics |

| Future of Guide Bearings | IoT monitoring, eco-materials |

| Troubleshooting Problems | Noise, vibration, excessive heat |

| Safety Considerations | Correct installation and use |

| Environmental Impact | Sustainability and recycling |

| FAQs | Common questions |

| Conclusion | Key insights |

Introduction

In every machine that moves, rotates, or glides, there’s a silent hero working behind the scenes — the guide bearing. From CNC machines and robotic arms to cars and jet engines, guide bearings ensure smooth, precise, and efficient motion.

Imagine running a CNC router without guide bearings. The result? Jerky cuts, misaligned tool paths, and excessive wear. Or think of a car without bearings in its wheels — friction would make even short trips impossible. Bearings may be small, but they play an enormous role in modern technology.

Guide Bearing

A guide bearing is a mechanical component that reduces friction between moving parts while guiding them along a defined path. Unlike plain bushings that rely on sliding contact, guide bearings use rolling elements like balls or rollers to minimize resistance.

Their main purpose is twofold: support loads (radial, axial, or both) and facilitate smooth motion. Whether in linear systems like CNC machines or rotational systems like wheel hubs, guide bearings are at the heart of precision motion.

History of Bearings

The concept of bearings dates back thousands of years. Ancient Egyptians used logs as rollers to move heavy stones. Later, Leonardo da Vinci sketched early designs of rolling-element bearings in the 15th century.

The industrial revolution brought mass production of bearings, with ball bearings revolutionizing machinery in the late 19th century. As technology advanced, so did bearing design — from simple steel balls to today’s hybrid ceramic bearings capable of extreme precision and durability.

Core Components

Every guide bearing shares common components:

Inner Race: Mounted on the rotating shaft.

Outer Race: Fixed to the housing.

Rolling Elements: Balls, rollers, or needles that reduce friction.

Cage or Retainer: Holds the rolling elements in place.

Seals/Shields: Protect against dust and contamination.

Lubrication: Oil or grease to reduce wear.

Each part must be manufactured with microscopic precision to ensure smooth, efficient operation.

How Guide Bearings Work

The working principle is elegantly simple: instead of sliding surfaces rubbing against each other, rolling elements move between the inner and outer races. This dramatically reduces friction, enabling smoother and more efficient motion.

Bearings can handle different load types:

Radial Loads: Forces perpendicular to the shaft (e.g., wheel bearings).

Axial Loads: Forces parallel to the shaft (e.g., thrust bearings).

Combined Loads: A mix of both (e.g., tapered roller bearings).

This versatility is why guide bearings are so widely used across industries.

Types of Guide Bearings

Guide bearings come in several varieties, each designed to meet specific load and motion requirements:

Ball Bearings: The most common type, using spherical rolling elements. Known for versatility and efficiency, they are found in everything from skateboards to CNC routers.

Roller Bearings: Instead of balls, they use cylindrical rollers, making them better at handling heavier loads.

Thrust Bearings: Designed specifically for axial loads. Common in automotive clutches and rotating tables.

Needle Bearings: A compact design using thin rollers, ideal for space-limited applications.

Tapered Roller Bearings: Handle both axial and radial loads. Widely used in automotive wheel hubs.

Spherical Bearings: Allow for angular misalignment while maintaining load support.

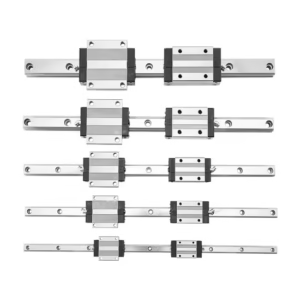

Linear Guide Bearings: Used in CNCs, 3D printers, and robotics for smooth linear motion.

Each type has strengths and limitations, and engineers select them based on speed, load, and precision needs.

Key Features

When evaluating guide bearings, the following features are critical:

Load Capacity: Determines how much weight the bearing can support without failure.

Accuracy: High-precision bearings maintain consistent tolerances in demanding applications.

Durability: Hardened materials and coatings increase service life.

Low Friction: Essential for energy efficiency and reduced heat generation.

Vibration Resistance: Prevents wear and ensures smoother operation.

Noise Reduction: Critical in medical devices and consumer electronics.

The balance of these features is what makes guide bearings indispensable for both heavy-duty industrial equipment and delicate surgical robots.

Materials Used

The performance of a guide bearing depends heavily on its material:

Carbon Steel: Affordable and strong, though prone to rust without coatings.

Stainless Steel: Corrosion-resistant, ideal for food, medical, and outdoor applications.

Ceramic: Lightweight, heat-resistant, and nearly frictionless. Perfect for aerospace and high-speed machinery.

Hybrid Bearings: Combine steel races with ceramic rolling elements for the best of both worlds.

Polymer Bearings: Lightweight, corrosion-resistant, and self-lubricating. Used in cleanrooms and chemical environments.

Material selection is often a trade-off between cost, durability, and environment.

Guide Bearings in CNC Machines

CNC machines rely on guide bearings to maintain precise tool paths.

Benefits in CNCs include:

Accuracy: Keeps tools aligned for micron-level precision.

Smooth Motion: Reduces chatter and vibration during cutting.

Durability: Withstands millions of high-speed cycles.

Efficiency: Minimizes downtime and maintenance.

For hobbyist CNC routers, inexpensive ball bearings are often used. Industrial CNCs, however, employ high-grade, preloaded linear guide bearings that provide flawless performance under heavy loads.

Applications in Robotics

Robots, both industrial and collaborative, depend heavily on bearings.

Examples include:

Robotic Arms: Bearings guide joints and actuators for precise motion.

Pick-and-Place Machines: High-speed bearings allow for rapid yet accurate part handling.

Medical Robots: Sterile stainless-steel bearings ensure reliability in surgical environments.

Cobots: Lightweight hybrid bearings improve speed while reducing energy use.

Without guide bearings, robotics would be plagued by jerky, inefficient movements.

Use in 3D Printing

In 3D printers, smooth motion determines print quality.

Linear Guide Bearings: Ensure consistent movement of the print head.

Reduced Banding: Bearings prevent layer misalignment.

Lightweight Designs: Help smaller printers achieve faster speeds.

Durability: Bearings maintain precision even after thousands of prints.

Many 3D printing enthusiasts upgrade stock bushings to linear ball bearings for higher precision.

Automotive Applications

Guide bearings are essential to modern cars.

Wheel Bearings: Allow wheels to rotate smoothly while handling massive radial loads.

Transmission Bearings: Reduce friction between gears for efficiency.

Suspension Bearings: Provide stability and absorb vibrations.

Steering Bearings: Ensure smooth and accurate steering control.

In vehicles, bearing failure can lead to dangerous conditions, making durability critical.

Aerospace Applications

Few industries demand more from bearings than aerospace.

Jet Engines: Bearings must withstand extreme speeds, temperatures, and forces.

Landing Gear: Guide bearings absorb the shock of touchdown.

Avionics: Precision bearings ensure accuracy in navigation instruments.

Spacecraft: Bearings are designed to function in vacuum environments with special lubricants.

Here, reliability is literally a matter of life and death.

Benefits of Guide Bearings

The widespread use of guide bearings comes down to their many advantages:

Reduced Friction: Less energy wasted, smoother operation.

Higher Efficiency: Machines run faster and cooler.

Longevity: Properly maintained bearings last years.

Precision: Critical in manufacturing, robotics, and aerospace.

Load Handling: Support both radial and axial loads with ease.

Versatility: Found in everything from toys to satellites.

These benefits explain why guide bearings remain one of the most important mechanical components ever developed.

Common Issues

Despite their durability, bearings are not indestructible. Common problems include:

Misalignment: Causes uneven wear and vibration.

Overheating: Often due to poor lubrication.

Contamination: Dust or chips can damage rolling elements.

Excessive Wear: Caused by overload or poor-quality bearings.

Noise: Often the first sign of bearing failure.

Catching these issues early prevents catastrophic equipment failure.

Maintenance Best Practices

Like any precision component, guide bearings require care to maintain performance. Proper maintenance extends service life, reduces downtime, and keeps machinery running smoothly.

Regular Cleaning: Dust, chips, and debris accumulate on bearings, especially in CNC machines. Wipe them clean periodically.

Lubrication: Always ensure bearings are lubricated with the recommended oil or grease. Lack of lubrication leads to heat buildup and wear.

Seal Integrity: Check seals and shields regularly to ensure contaminants don’t enter.

Temperature Monitoring: Overheating often signals lubrication failure or overloading.

Alignment Checks: Misaligned bearings wear out faster and may cause machinery vibration.

Replacement Schedules: Don’t wait for failure. Proactively replace bearings after set usage cycles.

When followed, these practices keep guide bearings reliable for millions of cycles.

Choosing the Right Bearing

Not all guide bearings fit every application. Selecting the wrong one can shorten equipment lifespan. Key considerations include:

Load Requirements: Radial, axial, or combined loads?

Speed: High-speed machinery requires low-friction, precision bearings.

Environment: Dusty, humid, sterile, or high-temperature environments demand specialized materials.

Precision Level: Consumer devices can use general-purpose bearings, but aerospace and medical require ultra-precision.

Budget: High-end bearings may seem costly, but they reduce maintenance expenses long-term.

The golden rule: choose based on performance, not just price.

Bearings vs. Bushings

A common question is whether to use bearings or bushings.

| Feature | Guide Bearings | Bushings |

|---|---|---|

| Friction | Very low, rolling motion | Higher, sliding motion |

| Load Capacity | Excellent for rotating and linear loads | Good for heavy static loads |

| Precision | High accuracy | Less precise |

| Speed Capability | Suitable for high speeds | Limited to low speeds |

| Maintenance | Requires lubrication | Some self-lubricating |

| Cost | More expensive | Affordable |

Bushings are simple, cheap, and rugged, while guide bearings are superior for smoothness and efficiency.

DIY Applications

The maker community loves guide bearings for their versatility. Popular DIY uses include:

CNC Routers: Bearings help gantries glide effortlessly.

3D Printers: Replacing bushings with linear guide bearings improves print accuracy.

Camera Sliders: Photographers use bearings for buttery-smooth tracking shots.

Robotics Projects: Bearings allow hobby robots to move like industrial models.

Laser Engravers: Guide bearings maintain consistent paths for engraving precision.

Because bearings are widely available and inexpensive, they’re a staple in workshops worldwide.

Cost Considerations

Guide bearing costs vary depending on type, size, and quality:

Budget Bearings: $2–$15 each, suitable for small DIY projects.

Mid-Range Bearings: $20–$100, used in semi-professional CNCs and robotics.

Industrial Bearings: $200–$500+, designed for aerospace, automotive, and medical equipment.

Other factors influencing price:

Material Choice: Stainless steel and ceramics cost more than carbon steel.

Precision Level: Tight tolerances raise costs significantly.

Brand: Premium brands like SKF or NSK cost more but deliver reliability.

Ultimately, cheap bearings save money upfront but can cause downtime and higher costs later.

Top Manufacturers

Several global leaders dominate the guide bearing market:

SKF (Sweden): Known for innovation and reliability.

NSK (Japan): Specializes in precision bearings for automotive and robotics.

NTN (Japan): Offers both industrial and general-purpose bearings.

Timken (USA): Focuses on tapered roller and industrial bearings.

FAG (Germany): Part of Schaeffler Group, famous for high-performance bearings.

For DIY projects, budget-friendly brands on platforms like Amazon and Misumi offer accessible alternatives.

Industry-Specific Uses

Guide bearings play critical roles across industries:

Medical Devices: Imaging systems, surgical robots, and diagnostic tools.

Electronics: Pick-and-place machines for circuit boards.

Packaging: High-speed packaging systems rely on low-friction bearings.

Renewable Energy: Wind turbines use massive roller bearings.

Agriculture: Bearings in tractors and combines withstand dirt and shock loads.

Every sector tailors bearing designs to its environmental and performance needs.

Innovations in Guide Bearings

Recent advances have made bearings smarter, lighter, and more efficient:

Self-Lubricating Bearings: Reduce the need for manual lubrication.

Hybrid Ceramics: Combine steel races with ceramic balls for speed and longevity.

Magnetic Bearings: Use magnetic fields to suspend motion without contact.

Noise-Reduction Designs: Special coatings and shapes reduce vibration.

Smart Bearings: Equipped with sensors to monitor load, speed, and wear in real time.

These innovations extend lifespan, reduce costs, and make bearings more eco-friendly.

Future of Guide Bearings

The next generation of guide bearings is being shaped by automation, sustainability, and digitalization.

IoT Connectivity: Smart bearings that send maintenance alerts.

AI Monitoring: Predictive analysis for wear and performance.

Eco-Friendly Materials: Recyclable metals and biodegradable lubricants.

Miniaturization: Ultra-small bearings for nanotech and electronics.

Lightweight Alloys: For aerospace and robotics efficiency.

The future is connected, sustainable, and precise.

Troubleshooting Problems

Even with careful use, bearings can face problems. Here are common fixes:

Noisy Bearings: Usually due to contamination or lack of lubrication.

Excessive Heat: Signals overload or lubrication failure.

Vibration: Often caused by misalignment or imbalance.

Premature Wear: Suggests poor installation or undersized bearings.

Corrosion: Indicates a need for stainless steel or protective coatings.

Addressing issues quickly prevents larger failures.

Safety Considerations

Guide bearings may seem simple, but they require safe handling:

Proper Installation: Incorrect mounting leads to failure.

Load Limits: Never exceed rated load capacity.

Protective Gear: Gloves and safety glasses when handling lubricated bearings.

Lockout Procedures: Shut down machines before bearing maintenance.

Temperature Awareness: Bearings in high-speed machines can get dangerously hot.

Safety ensures both machine longevity and operator well-being.

Environmental Impact

Bearings are evolving to meet sustainability goals:

Recyclability: Steel and ceramic bearings can be recycled after use.

Energy Efficiency: Reduced friction means lower energy consumption.

Eco-Friendly Lubricants: Biodegradable greases reduce environmental harm.

Durability: Longer lifespan means less frequent replacements.

Green engineering practices are pushing the industry toward more sustainable solutions.

FAQs

What is the purpose of a guide bearing?

It reduces friction while supporting and guiding moving parts in machinery.

What types of loads can bearings handle?

Bearings can support radial, axial, or combined loads depending on design.

Do bearings need lubrication?

Yes, lubrication is essential for smooth operation and longevity.

What’s the difference between ball and roller bearings?

Ball bearings are versatile and efficient, while roller bearings handle heavier loads.

How long do guide bearings last?

With proper maintenance, they can last millions of cycles.

Can I use guide bearings in DIY projects?

Absolutely — they’re widely used in hobby CNCs, 3D printers, and camera rigs.

Conclusion

The guide bearing may be small, but its impact is enormous. From industrial robots and CNC machines to cars and airplanes, these precision components keep the world moving.

Their ability to reduce friction, support loads, and maintain accuracy makes them essential in nearly every field of engineering. With innovations like smart sensors, hybrid materials, and eco-friendly designs, guide bearings are poised to remain at the core of modern motion systems for decades to come.

For engineers, hobbyists, and manufacturers alike, understanding guide bearings isn’t just about mechanics — it’s about building smoother, more efficient, and more sustainable futures.

Suggested Inbound Links:

[Linear Guide Shaft Applications]

[Linear Rails vs. Bearings Comparison]

[CNC Machine Components Guide]

Suggested Outbound Links: