Linear bearing blocks are essential components in modern machinery, enabling precise, smooth, and low-friction linear motion. Used in CNC machines, 3D printers, automation systems, robotics, and laboratory equipment, linear bearing blocks provide stability, load distribution, and high accuracy in linear motion applications.

This guide explores the components, types, mechanics, materials, advantages, applications, installation, maintenance, and troubleshooting of linear bearing blocks. By understanding these elements, engineers, technicians, and enthusiasts can optimize the performance of linear motion systems and extend their operational life.

Table of Contents

What Is a Linear Bearing Block?

Components of a Linear Bearing Block

Types of Linear Bearing Blocks

Design Principles and Mechanics

Materials Used in Linear Bearing Blocks

Advantages of Linear Bearing Blocks

Applications Across Industries

Selection Criteria

Installation and Alignment

Maintenance and Lubrication

Common Issues and Troubleshooting

Innovations and Future Trends

Frequently Asked Questions

Conclusion

1. What Is a Linear Bearing Block?

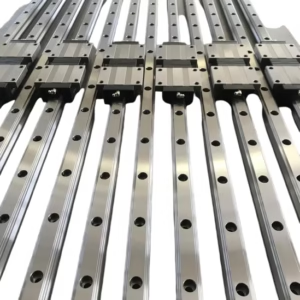

A linear bearing block, also called a linear guide block or linear slide block, is a mechanical component that allows smooth, precise movement along a linear guide rail. It typically contains rolling elements, such as balls or rollers, which reduce friction between the block and rail.

Linear bearing blocks are critical in applications where accuracy, repeatability, and reliability are required. They are widely used in both heavy industrial machinery and compact precision instruments.

2. Components of a Linear Bearing Block

A typical linear bearing block consists of several key components:

2.1 Housing

The housing, usually made of steel or aluminum, holds the internal components and provides structural support. It is precision-machined for exact fit with the guide rail.

2.2 Rolling Elements

These are usually ball bearings or cylindrical rollers that circulate within the block, providing low-friction movement and even load distribution.

2.3 Ball Circulation System

Ball circulation channels guide the balls within the block, ensuring continuous motion and preventing jamming.

2.4 End Caps

End caps prevent the balls from falling out and help redirect the balls for recirculation within the block.

2.5 Lubrication Ports

Many blocks feature lubrication ports or grooves for oil or grease, reducing friction and wear and extending the block’s lifespan.

3. Types of Linear Bearing Blocks

Linear bearing blocks come in various designs to meet specific performance requirements:

3.1 Profile Rail Blocks

Design: Rectangular or square housing with recirculating ball system.

Use: CNC machines, automation, and precision machinery.

Advantages: High load capacity, rigidity, and accuracy.

3.2 Round Shaft Blocks

Design: Circular guide rails with cylindrical blocks.

Use: Light-load and small-scale machinery.

Advantages: Compact design, easy installation.

3.3 Miniature Blocks

Design: Small-scale blocks for limited space.

Use: Laboratory instruments, small robotics, 3D printers.

Advantages: High precision in compact form factor.

3.4 Cross-Roller Linear Blocks

Design: Roller bearings arranged perpendicularly to handle multi-directional loads.

Use: Robotics, precision rotary tables.

Advantages: Handles axial, radial, and moment loads efficiently.

4. Design Principles and Mechanics

4.1 Recirculation Mechanism

Linear bearing blocks typically use a recirculating ball system. Balls travel along channels within the block and are returned through end caps or circulation pathways, providing continuous low-friction motion.

4.2 Load Distribution

Properly designed linear bearing blocks distribute loads evenly across the rail. This prevents localized wear and ensures long-lasting, precise motion.

4.3 Friction Reduction

Rolling elements drastically reduce friction compared to sliding systems, enabling smoother motion, faster operation, and lower energy consumption.

4.4 Rigidity and Accuracy

Profiled blocks increase rigidity and reduce deflection, essential for high-precision applications such as CNC machining, automation, and medical instruments.

5. Materials Used in Linear Bearing Blocks

Material choice affects performance, wear resistance, and longevity.

5.1 Steel

High strength and durability

Heat-treated for hardness and wear resistance

Common in industrial applications

5.2 Stainless Steel

Corrosion-resistant, suitable for humid, wet, or chemical environments

Often used in food, pharmaceutical, and medical applications

5.3 Aluminum

Lightweight and corrosion-resistant

Used in aerospace or portable machinery

5.4 Plastics and Polymers

Used for cages, seals, and low-friction components

Reduce noise and allow cleanroom compatibility

6. Advantages of Linear Bearing Blocks

Linear bearing blocks offer many benefits:

Precision: Maintains accurate linear motion.

Low Friction: Smooth motion with minimal wear.

High Load Capacity: Handles axial, radial, and moment loads efficiently.

Durability: Long lifespan with proper maintenance.

Versatility: Adaptable to various machines and industrial processes.

Noise Reduction: Rolling elements reduce operational noise.

7. Applications Across Industries

7.1 CNC Machinery

Linear bearing blocks guide tools, spindles, and tables for high-precision cutting and milling.

7.2 3D Printing

Provide smooth movement of print heads and build plates, ensuring accurate layer deposition.

7.3 Robotics

Used in robotic arms and automated assembly lines for accurate, repeatable linear motion.

7.4 Automation and Packaging

Critical in pick-and-place machines, conveyors, and automated packaging systems.

7.5 Medical Devices

Supports motion in imaging equipment, surgical robots, and laboratory instruments.

7.6 Aerospace

Applied in flight simulators, satellite positioning, and aerospace manufacturing tools.

8. Selection Criteria

When selecting a linear bearing block:

Load Capacity: Consider both dynamic and static loads.

Precision: Look at tolerance, smoothness, and repeatability.

Speed: High-speed applications require optimized bearing designs.

Environmental Conditions: Consider temperature, humidity, and contaminants.

Size and Weight Constraints: Choose blocks compatible with space limitations.

Maintenance: Some blocks require more frequent lubrication than others.

9. Installation and Alignment

Proper installation ensures optimal performance:

9.1 Surface Preparation

Mounting surfaces must be flat, clean, and rigid.

9.2 Alignment

Rails must be parallel and straight. Misalignment leads to uneven wear and decreased accuracy.

9.3 Fastening

Use correct torque specifications; over-tightening can distort the block or rail.

9.4 Testing

Check smooth movement under load before operational use.

10. Maintenance and Lubrication

Regular maintenance prolongs operational life:

Cleaning: Remove dust, debris, and contaminants.

Lubrication: Apply compatible grease or oil.

Inspection: Monitor for wear, corrosion, or damage.

Replacement: Replace worn components promptly.

11. Common Issues and Troubleshooting

Common problems include:

Noise or Vibration: Often caused by misalignment or insufficient lubrication.

Sticking or Jamming: Caused by dirt, debris, or damaged balls.

Excessive Wear: Results from overload or contamination.

Corrosion: Occurs in humid, wet, or chemically aggressive environments.

12. Innovations and Future Trends

High-Speed Blocks: Optimized for ultra-fast automation systems.

Compact Designs: Smaller blocks with maintained load capacity.

Integrated Sensors: Load monitoring and predictive maintenance.

Advanced Materials: Coatings and plastics for reduced friction and improved durability.

13. Frequently Asked Questions

Q1: What is the difference between a linear bearing block and a linear guide rail?

A1: The block provides the moving carriage, while the rail is the stationary guide. Together, they enable smooth linear motion.

Q2: Can linear bearing blocks be used outdoors?

A2: Stainless steel or coated blocks are suitable for outdoor and humid conditions.

Q3: How often should linear bearing blocks be lubricated?

A3: Depending on usage, lubrication may be needed weekly, monthly, or as recommended by the manufacturer.

Q4: What is the typical lifespan of a linear bearing block?

A4: With proper installation, alignment, and maintenance, blocks can last many years, even in demanding industrial applications.

14. Conclusion

Linear bearing blocks are critical in providing precise, low-friction, and reliable linear motion across a wide range of applications. With careful selection, correct installation, and routine maintenance, they can significantly enhance the performance and longevity of machinery in CNC machining, robotics, automation, 3D printing, medical devices, and aerospace systems.