Outline for Linear Bearings

| Main Topic | Subtopics |

|---|---|

| Introduction to Linear Bearings | Definition of linear bearings, Why linear bearings matter, Historical background of linear motion systems |

| How Linear Bearings Work | Basic working principle, Components and structure, Motion efficiency |

| Types of Linear Bearings | Ball bushing bearings, Roller linear bearings, Plain linear bearings, Air bearings, Magnetic bearings |

| Materials in Linear Bearings | Steel, Ceramics, Polymers, Hybrid designs |

| Design Features of Linear Bearings | Load handling, Friction reduction, Alignment precision, Durability |

| Advantages of Linear Bearings | Smooth operation, Energy efficiency, Cost savings, Reliability |

| Limitations of Linear Bearings | Sensitivity to contamination, Limited load capacity, Cost considerations |

| Applications of Linear Bearings | Industrial automation, Robotics, 3D printing, Aerospace, Medical technology |

| Linear Bearings vs. Linear Guides | Key differences, When to choose one over the other |

| Linear Bearings vs. Rotary Bearings | Applications comparison, Advantages of each |

| Choosing the Right Linear Bearing | Factors to consider, Load and speed, Environment conditions, Cost vs. performance |

| Installation Best Practices | Proper alignment, Mounting methods, Avoiding common errors |

| Maintenance of Linear Bearings | Cleaning, Lubrication schedules, Inspection routines |

| Lubrication in Linear Bearings | Types of lubricants, Grease vs. oil, Dry lubrication options |

| Reducing Friction in Linear Bearings | Techniques, Benefits of low-friction design |

| Troubleshooting Common Issues | Noise, Wear, Vibration, Misalignment |

| Linear Bearings in Robotics | Role in automation, Enhancing precision, Case studies |

| Linear Bearings in 3D Printing | Motion quality, Print accuracy, Longevity |

| Linear Bearings in Medical Equipment | Imaging systems, Surgical robots, Laboratory devices |

| Market Trends in Linear Bearings | Global demand, Innovations, Key manufacturers |

| Future of Linear Bearings | Smart sensors, IoT integration, Nanotechnology |

| DIY Projects Using Linear Bearings | CNC builds, Camera sliders, Automation projects |

| Cost of Linear Bearings | Pricing ranges, Factors affecting cost, Budget-friendly options |

| Eco-Friendly Aspects of Linear Bearings | Sustainable materials, Energy efficiency |

| FAQs on Linear Bearings | Common questions with answers |

| Conclusion on Linear Bearings | Key takeaways, Future outlook |

Introduction to Linear Bearings

A linear bearing is a specialized component designed to provide precise, low-friction movement along a straight path. Unlike rotary bearings, which enable circular motion, linear bearings excel at sliding, gliding, or rolling in a single direction. They are found in an astonishing range of technologies, from industrial machines and robotics to medical equipment and 3D printers.

The concept of linear motion systems can be traced back to ancient times when wooden and bronze sliding mechanisms were lubricated with animal fats or oils. As industrialization advanced, the invention of ball and roller bearings revolutionized how machines moved, reducing friction drastically and boosting performance.

Today, linear bearings have evolved into highly sophisticated designs using advanced alloys, ceramics, engineered plastics, and even magnetic or air-based systems, all tailored for efficiency, precision, and durability.

How Linear Bearings Work

Linear bearings work by creating a rolling or sliding interface between a moving element (like a carriage or block) and a fixed element (like a shaft or rail). This setup:

- Reduces friction and resistance.

- Distributes loads evenly across rolling elements or surfaces.

- Ensures smooth and accurate motion.

A typical design includes a shaft, housing, rolling elements (balls or rollers), and retainers. By minimizing surface contact, linear bearings extend service life while maintaining high precision and efficiency.

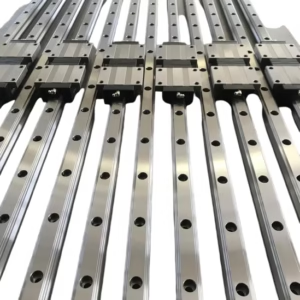

Types of Linear Bearings

Different designs serve different applications:

- Ball Bushing Bearings – Cylindrical housings with recirculating steel or ceramic balls, offering high precision.

- Roller Linear Bearings – Use cylindrical rollers for handling heavier loads.

- Plain Linear Bearings – No rolling elements; instead, sliding surfaces (often polymer-based) provide smooth, self-lubricating movement.

- Air Bearings – Float on a thin film of air, eliminating contact and friction, ideal for precision instruments.

- Magnetic Bearings – Rely on magnetic levitation, enabling contact-free, ultra-smooth motion.

Materials in Linear Bearings

- Steel Bearings: Strong, durable, cost-effective.

- Ceramic Bearings: Lightweight, corrosion-resistant, great for high-speed use.

- Polymer Bearings: Low-cost, self-lubricating, ideal for dirty environments.

- Hybrid Bearings: Combine steel and ceramic for balance in performance.

Design Features of Linear Bearings

Key characteristics include:

- Load Capacity – Ability to carry axial and radial forces.

- Friction Reduction – Efficiency in reducing resistance during movement.

- Alignment Precision – Maintains accuracy even under repetitive use.

- Durability – Resistance to wear and environmental conditions.

Advantages of Linear Bearings

- Smooth, consistent operation.

- Energy efficiency due to reduced resistance.

- Minimal maintenance with sealed or self-lubricating types.

- Cost savings from longer equipment life.

Limitations of Linear Bearings

- Susceptible to contamination by dust or debris.

- Load capacity limitations in some designs.

- Advanced options like air or magnetic bearings can be expensive.

Applications of Linear Bearings

- Industrial Automation – CNC machines, assembly lines.

- Robotics – For high-precision motion in robotic arms.

- 3D Printing – Ensures smooth layer deposition.

- Aerospace – Testing systems, navigation equipment.

- Medical Technology – Imaging machines, surgical robots.

Linear Bearings vs. Linear Guides

- Linear Bearings – Provide rolling/sliding motion.

- Linear Guides – Provide structural support and rigidity.

Linear Bearings vs. Rotary Bearings

- Linear Bearings – Motion in straight lines.

- Rotary Bearings – Motion around an axis.

Choosing the Right Linear Bearing

When selecting:

- Consider load requirements.

- Check speed and precision needs.

- Factor in operating environment.

- Balance performance with budget.

Installation Best Practices

- Ensure shaft alignment.

- Avoid misalignment that causes wear.

- Follow proper mounting procedures.

Maintenance of Linear Bearings

- Regular cleaning to prevent dust accumulation.

- Lubrication to minimize friction.

- Inspection for wear or misalignment.

Lubrication in Linear Bearings

- Grease Lubrication: Long-lasting protection.

- Oil Lubrication: Ideal for high-speed applications.

- Dry Film Lubrication: Clean-room and contamination-sensitive environments.

Reducing Friction in Linear Bearings

- Use of high-quality lubricants.

- Precision alignment.

- Use of advanced materials like ceramics.

Troubleshooting Common Issues

- Noise: Often caused by poor lubrication.

- Wear: Indicates misalignment or contamination.

- Vibration: Results from incorrect installation.

Linear Bearings in Robotics

- Enhance automation accuracy.

- Enable smooth, repetitive motions.

- Support precision in robotic arms.

Linear Bearings in 3D Printing

- Deliver consistent print quality.

- Reduce layer shifting and misalignment.

- Ensure longer printer lifespan.

Linear Bearings in Medical Equipment

- Used in scanners and diagnostic tools.

- Essential in robot-assisted surgeries.

- Applied in lab automation systems.

Market Trends in Linear Bearings

- Rising demand in automation and robotics.

- Innovations in smart, self-lubricating designs.

- Leading manufacturers: THK, NSK, SKF, Bosch Rexroth.

Future of Linear Bearings

- IoT-enabled smart monitoring.

- Nanotechnology for ultra-precise movement.

- Wider use of eco-friendly materials.

DIY Projects Using Linear Bearings

- CNC machines built at home.

- Camera sliders for filmmakers.

- Custom automation systems.

Cost of Linear Bearings

- Standard bearings: $10–$50.

- Heavy-duty bearings: $100–$500.

- Air/magnetic bearings: Thousands.

Eco-Friendly Aspects of Linear Bearings

- Energy savings due to reduced friction.

- Use of recyclable metals and polymers.

- Adoption of green lubricants.

FAQs on Linear Bearings

What is a linear bearing used for?

It allows smooth, low-friction linear motion in machines and devices.

Do linear bearings need lubrication?

Yes, unless self-lubricating polymer bearings are used.

How do linear bearings differ from linear guides?

Bearings enable motion, while guides provide structure.

What industries use linear bearings the most?

Robotics, aerospace, manufacturing, and healthcare.

Are linear bearings expensive?

Prices vary widely, from a few dollars to thousands.

How long do linear bearings last?

With proper maintenance, several years or more.

Conclusion on Linear Bearings

Linear bearings may seem like small components, but they are fundamental to modern engineering and technology. From CNC machining to robotics, 3D printing, and medical precision tools, they ensure smooth, accurate, and durable linear motion.

As industries shift toward smart automation and eco-friendly designs, linear bearings will continue to evolve with advanced materials, integrated sensors, and nanotechnology. For engineers, makers, and innovators, understanding linear bearings means unlocking the potential for greater efficiency and precision in every project.

Suggested Inbound Links

- Guide to CNC Machines

- Robotics Engineering Basics

- Introduction to Precision Manufacturing