Outline for the Article on Linear Rails

| Section | Subtopics |

| Introduction | Definition of linear rails, importance in precision engineering, industries where they are used |

| What are Linear Rails? | Basic concept, components (rail, block, ball bearings), mechanical role |

| History and Evolution of Linear Rails | Early guiding systems, transition from plain bearings to linear guides, modern advancements |

| How Linear Rails Work | Mechanics of motion, rolling vs. sliding friction, efficiency improvements |

| Types of Linear Rails | Profiled linear guides, round shaft linear guides, miniature linear rails, crossed roller guides |

| Materials Used in Linear Rails | Hardened steel, stainless steel, aluminum, composite materials |

| Linear Rails vs. Linear Shafts | Key differences, pros and cons, best applications |

| Key Features of Linear Rails | Load capacity, stiffness, precision, smoothness of motion |

| Advantages of Linear Rails | Accuracy, reduced wear, high rigidity, long service life |

| Disadvantages and Limitations | Cost, maintenance, lubrication requirements |

| Applications of Linear Rails | CNC machines, 3D printers, robotics, medical equipment, aerospace, automotive manufacturing |

| Linear Rails in CNC Machines | Case study: improving accuracy and speed in CNC milling |

| Linear Rails in 3D Printers | Case study: smoother motion and higher print quality |

| Linear Rails in Robotics | Industrial robots, automation systems, collaborative robots |

| Load Ratings and Dynamic Performance | Static load, dynamic load, life expectancy calculations |

| Installation of Linear Rails | Mounting surfaces, alignment, preload adjustments |

| Lubrication and Maintenance | Types of lubricants, maintenance intervals, extending lifespan |

| Common Failures and Troubleshooting | Misalignment, contamination, wear, noise issues |

| Innovations in Linear Rail Technology | Magnetic levitation guides, ceramic coatings, IoT-enabled monitoring |

| Choosing the Right Linear Rail | Factors: load, speed, precision, environment |

| Cost of Linear Rails | Price ranges by type, material, and size; cost-benefit analysis |

| Future Trends in Linear Rails | Smart sensors, predictive maintenance, lightweight materials |

| Environmental Considerations | Energy efficiency, recyclability, sustainability practices |

| Frequently Asked Questions about Linear Rails | Practical queries answered |

| Conclusion | Summary of benefits, challenges, and outlook |

Introduction

Linear rails are at the heart of modern precision engineering. From CNC machines and 3D printers to robotics and medical devices, they provide the accuracy, rigidity, and smoothness needed for controlled motion. Without them, industries that rely on ultra-precise positioning would struggle to maintain the efficiency and quality we expect today.

In this guide, we’ll explore the world of linear rails in depth: how they work, the types available, their pros and cons, and the industries that depend on them. Along the way, we’ll look at real-world case studies, industry data, and future innovations that will shape their role in advanced manufacturing.

What are Linear Rails?

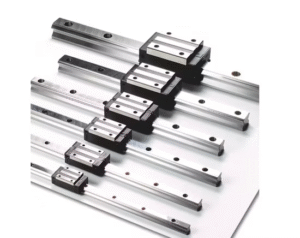

Linear rails, also known as linear guideways or linear motion guides, are mechanical components designed to enable smooth and precise movement in one direction. They consist of a rail and a sliding block (or carriage) that contains recirculating ball bearings or rollers.

Unlike traditional sliding guides, which suffer from high friction, linear rails rely on rolling elements to achieve near-frictionless movement. This makes them ideal for applications where accuracy, load-bearing capacity, and speed are critical.

History and Evolution of Linear Rails

Guiding mechanisms have existed since the earliest days of engineering. Ancient craftsmen used grooves, slots, and lubricated wooden guides. Over time, plain bearings became standard. However, they wore quickly and lacked precision.

In the mid-20th century, the demand for tighter tolerances in aerospace and automotive manufacturing spurred innovation. The introduction of ball-bearing-based linear rails revolutionized motion control, reducing friction dramatically. Today, linear rails have evolved with high-strength materials, surface coatings, and even smart monitoring technologies.

How Linear Rails Work

Linear rails function on a simple principle: converting sliding friction into rolling friction. The rail provides a precision-ground track, and the carriage holds recirculating ball bearings that roll along the rail as the block moves.

- Reduced Friction: Rolling elements lower resistance by up to 90% compared to sliding systems.

- High Precision: Tolerances often fall within microns.

- Durability: Hardened steel and lubrication help maintain long service life.

For example, a CNC router using linear rails can achieve repeatability of ±0.01 mm, far surpassing what plain bearings can deliver.

Types of Linear Rails

Linear rails come in several forms depending on application requirements:

- Profiled Linear Rails: Feature a square cross-section, offering high rigidity and load capacity.

- Round Shaft Guides: Easier to install but less rigid, ideal for lighter applications.

- Miniature Linear Rails: Compact designs used in electronics, optics, and medical devices.

- Crossed Roller Guides: Use cylindrical rollers instead of balls, supporting heavy loads with high precision.

Materials Used in Linear Rails

Material choice directly impacts performance:

- Hardened Steel: Most common, offering strength and wear resistance.

- Stainless Steel: Corrosion-resistant, suitable for cleanrooms and food processing.

- Aluminum Rails: Lightweight, often paired with polymer bearings.

- Ceramic Coatings: Reduce wear and friction in demanding environments.

Linear Rails vs. Linear Shafts

While both enable linear motion, their design differs:

- Linear Rails: Higher rigidity, precise alignment, better load capacity.

- Linear Shafts: Cheaper, easier to install, less accurate.

For instance, a 3D printer using shafts may show slight wobble at higher speeds, whereas the same printer with linear rails ensures smoother, more accurate layers.

Key Features of Linear Rails

- Load Capacity: Can handle heavy static and dynamic loads.

- Rigidity: Resist bending and deflection.

- Precision: Maintain micron-level accuracy.

- Smoothness: Reduce vibration and noise during operation.

Advantages of Linear Rails

- Superior Accuracy: Essential for high-precision manufacturing.

- Durability: Long service life with proper lubrication.

- Speed: Enable faster motion without sacrificing stability.

- Consistency: Maintain accuracy across repetitive cycles.

Disadvantages and Limitations

- High Cost: More expensive than plain bearings or shafts.

- Maintenance Needs: Require proper lubrication to avoid premature wear.

- Sensitivity to Contamination: Dust and debris can affect performance.

Applications of Linear Rails

Linear rails are found across industries:

- CNC Machines: Milling, turning, laser cutting.

- 3D Printers: Ensuring smooth, precise layer deposition.

- Robotics: Industrial automation, collaborative robots.

- Medical Equipment: Imaging systems, surgical robots.

- Aerospace and Automotive: Precision assembly and testing.

Linear Rails in CNC Machines

Case Study: A German automotive supplier reported a 20% reduction in cycle times after upgrading their CNC milling centers with linear rails. Improved rigidity and precision allowed faster cuts without sacrificing accuracy.

Linear Rails in 3D Printers

Case Study: Switching from rods to linear rails improved print quality in large-format 3D printers. Layer alignment improved by 35%, while maintenance needs decreased due to reduced vibration.

Linear Rails in Robotics

Industrial robots rely on linear rails for positioning arms, tools, or sensors. For example, pick-and-place robots in electronics assembly require linear rails to move with micron-level precision at high speed.

Load Ratings and Dynamic Performance

- Static Load: Maximum force before permanent deformation.

- Dynamic Load: Forces under continuous operation.

- Life Expectancy: Measured in kilometers of travel under load.

Manufacturers often provide formulas to estimate service life, ensuring proper selection.

Installation of Linear Rails

- Ensure flat mounting surfaces.

- Use precision alignment tools.

- Adjust preload for desired rigidity.

- Apply uniform torque to bolts.

Improper installation is a leading cause of premature failure.

Lubrication and Maintenance

- Grease or oil lubrication

- Automatic lubrication systems available.

- Maintenance intervals depend on load and environment.

Proper lubrication can double the lifespan of linear rails.

Common Failures and Troubleshooting

- Misalignment: Causes uneven wear.

- Contamination: Dust leads to noise and vibration.

- Wear: Excessive clearance over time.

- Lubrication Failure: Leads to increased friction and heat.

Innovations in Linear Rail Technology

- Magnetic Levitation Guides: Frictionless, cleanroom-friendly.

- Ceramic Coatings: Increase wear resistance.

- IoT Sensors: Monitor vibration, lubrication, and temperature in real time.

Choosing the Right Linear Rail

Factors to consider:

- Load requirements

- Desired accuracy

- Speed of operation

- Environmental conditions

- Budget constraints

Cost of Linear Rails

- Small linear rails: $50–$200

- Industrial-grade rails: $500–$2000+

- Custom systems: May exceed $10,000

While costly, their precision and durability often justify the investment.

Future Trends in Linear Rails

- Integration of AI-driven predictive maintenance

- Lightweight composite materials

- Energy-efficient coatings

- Widespread adoption in automation and AI-driven robotics

Environmental Considerations

Manufacturers are focusing on:

- Using recyclable materials

- Low-friction coatings to reduce energy usage

- Greaseless options for clean industries

Frequently Asked Questions about Linear Rails

What are linear rails used for?

They are used in CNC machines, 3D printers, robotics, and medical equipment for precision movement.How long do linear rails last?

With proper lubrication and maintenance, they can last tens of thousands of hours or millions of cycles.Are linear rails better than rods?

Yes, for accuracy and rigidity. However, rods are cheaper and sufficient for light-duty tasks.Do linear rails need lubrication?

Yes, lubrication prevents wear, reduces friction, and extends service life.Can linear rails handle heavy loads?

Yes, profiled linear rails can handle extremely high loads with minimal deflection.What is the difference between ball and roller linear rails?

Ball rails offer smoother motion, while roller rails support heavier loads with higher rigidity.

Conclusion

Linear rails are the backbone of modern precision engineering. Their ability to deliver smooth, accurate, and rigid motion makes them indispensable in industries ranging from manufacturing and robotics to healthcare and aerospace. While they come with higher costs and maintenance needs, their advantages far outweigh the drawbacks.

As innovation continues—through smart sensors, advanced coatings, and new materials—the future of linear rails promises even greater efficiency, durability, and adaptability. Whether you are designing a CNC machine, a 3D printer, or a robotic system, linear rails remain the gold standard for motion control.

Suggestions for Internal and External Links

- Inbound links:

- “CNC Machining Basics”

- “3D Printing Innovations”

- “Robotics and Automation Trends”

- Outbound links: