In the modern world of precision engineering, the linear guide block plays a central role in ensuring smooth, accurate, and controlled linear motion. It’s the critical moving part of a linear guide system, translating rotational motion into precise linear movement with minimal friction and maximum stability.

At YH Linear, our linear guide blocks are crafted with precision and innovation, ensuring reliability even in the most demanding industrial environments. Whether used in CNC machining, robotics, or automated assembly lines, YH Linear’s guide blocks are engineered for performance that stands the test of time.

This comprehensive article will explore what a linear guide block is, how it functions, its components, advantages, and why YH Linear is one of the world’s trusted names in precision motion systems.

Outline

| Section | Heading |

|---|---|

| 1 | Introduction to Linear Guide Block |

| 2 | What Is a Linear Guide Block? |

| 3 | The Function of a Linear Guide Block in Motion Systems |

| 4 | Structural Design of Linear Guide Blocks |

| 5 | Key Components and Materials |

| 6 | How a Linear Guide Block Works |

| 7 | Ball-Type vs Roller-Type Guide Blocks |

| 8 | Preload and Clearance Explained |

| 9 | Advantages of Using Linear Guide Blocks |

| 10 | Importance of Precision in Linear Guide Blocks |

| 11 | YH Linear Guide Block Technology |

| 12 | Types of Linear Guide Blocks |

| 13 | Standard Linear Guide Blocks |

| 14 | Flange Type Linear Guide Blocks |

| 15 | Long and Short Linear Guide Blocks |

| 16 | Heavy-Duty Linear Guide Blocks |

| 17 | Miniature Linear Guide Blocks |

| 18 | Stainless Steel Linear Guide Blocks |

| 19 | Aluminum Linear Guide Blocks |

| 20 | Surface Treatments and Coatings |

| 21 | Load Capacity and Rigidity Considerations |

| 22 | Common Applications of Linear Guide Blocks |

| 23 | Installation and Alignment Guidelines |

| 24 | Lubrication and Maintenance Practices |

| 25 | Common Issues and Troubleshooting |

| 26 | YH Linear’s Manufacturing and Quality Control |

| 27 | Customization and OEM Capabilities |

| 28 | Future Innovations in Linear Guide Block Design |

| 29 | FAQs About Linear Guide Blocks |

| 30 | Conclusion |

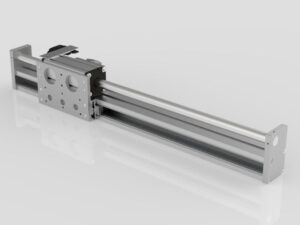

Linear Guide Block

A linear guide block—also known as a carriage or slider—is the moving component that travels along the linear guide rail. It supports and transfers loads while ensuring stable, low-friction linear motion.

At YH Linear, we design each linear guide block with precision-ground raceways and advanced circulation systems. Our blocks guarantee consistent motion performance under various loads and speeds, making them a perfect fit for CNC machines, industrial robots, and precision instruments.

What Is a Linear Guide Block?

A linear guide block is a mechanical part that moves along a linear rail, supported by recirculating rolling elements such as steel balls or rollers. It provides linear motion with high rigidity and accuracy.

The block’s structure ensures that loads from multiple directions can be supported, enabling the system to maintain precision even under vibration or stress.

YH Linear guide blocks are optimized for performance, combining tight tolerances, smooth motion, and long-lasting durability.

The Function of a Linear Guide Block in Motion Systems

The linear guide block serves three essential functions:

Load support: It distributes and transfers load evenly across the rail.

Guidance: It maintains the moving part’s linear path.

Friction reduction: Rolling elements inside the block minimize resistance for smooth travel.

In YH Linear systems, the block’s design allows for perfect ball circulation and minimal play, providing flawless performance in repetitive, high-speed operations.

Structural Design of Linear Guide Blocks

A linear guide block typically features:

A precision-machined steel body

Internal raceways matching the guide rail profile

End caps guiding the circulation of rolling elements

Protective seals at both ends

Lubrication ports for easy maintenance

YH Linear’s design ensures every component fits seamlessly, resulting in exceptional accuracy and durability.

Key Components and Materials

| Component | Function | Material |

|---|---|---|

| Block body | Main structural element | High-carbon steel or stainless steel |

| Rolling elements | Reduce friction | Hardened steel balls or rollers |

| End caps | Circulate rolling elements | High-strength polymer or metal |

| Seals and scrapers | Prevent contamination | Synthetic rubber or polymer |

| Lubrication port | Supplies lubricant | Brass or aluminum alloy |

YH Linear uses heat-treated and precision-ground materials to guarantee rigidity and long service life.

How a Linear Guide Block Works

Inside the block, rolling elements circulate in closed raceways. As the block moves along the rail, the balls or rollers roll smoothly, reducing friction to nearly zero.

The rolling motion allows:

High load capacity

Low wear

Accurate positioning

Silent operation

YH Linear optimizes the raceway curvature for even load distribution, extending both block and rail life.

Ball-Type vs Roller-Type Guide Blocks

| Type | Features | Applications |

|---|---|---|

| Ball Type | Smooth, fast, low noise | Robotics, 3D printing, light machinery |

| Roller Type | High rigidity, heavy loads | CNC, presses, automation lines |

YH Linear offers both types, engineered to match specific industry needs.

Preload and Clearance Explained

Preload eliminates clearance between the rail and block to increase stiffness and accuracy.

At YH Linear, we offer multiple preload levels—light, medium, and heavy—depending on the application’s rigidity and motion requirements.

The correct preload improves:

Positional repeatability

Load-bearing stability

Vibration resistance

Advantages of Using Linear Guide Blocks

High precision and repeatability

Minimal friction and energy loss

Long service life with proper lubrication

Easy assembly and alignment

Support for multi-directional loads

Compact design for space-saving installations

YH Linear’s guide blocks deliver all these benefits while maintaining competitive pricing and world-class quality.

Importance of Precision in Linear Guide Blocks

Precision determines how smoothly a machine performs.

At YH Linear, we maintain micron-level tolerances on every block. This ensures perfect rail fitment, zero backlash, and vibration-free movement.

Our precision results in longer tool life, quieter operation, and higher production efficiency for end users.

YH Linear Guide Block Technology

YH Linear’s proprietary design integrates:

Optimized raceway geometry for smooth ball circulation

Dust-proof seals for contamination resistance

Self-lubrication channels for low maintenance

Anti-corrosion coatings for extended durability

Each model undergoes CNC grinding and laser inspection, ensuring perfect alignment between rail and block.

Types of Linear Guide Blocks

YH Linear offers a wide range of guide blocks:

Standard blocks

Flange-type blocks

Short and long blocks

Heavy-duty blocks

Miniature blocks

Stainless steel and aluminum blocks

Each series is tailored for specific precision, load, and environmental conditions.

Standard Linear Guide Blocks

The most widely used type—ideal for general automation and machinery.

YH Linear’s standard blocks provide balanced performance across rigidity, size, and cost-efficiency.

Flange Type Linear Guide Blocks

Designed for stronger mounting and improved stability, flange blocks have a wider base.

They’re perfect for systems exposed to vibration or lateral forces.

Long and Short Linear Guide Blocks

Long blocks: Better load distribution, higher rigidity.

Short blocks: Compact size for lightweight or space-constrained systems.

YH Linear offers both styles in customizable lengths and materials.

Heavy-Duty Linear Guide Blocks

Engineered for industrial-scale loads, these blocks feature reinforced raceways and rollers.

They are commonly used in CNC machines, industrial presses, and robotic actuators.

Miniature Linear Guide Blocks

Tiny yet precise, miniature guide blocks (like YH Linear’s MGN series) are used in 3D printers, optical equipment, and semiconductor tools.

They ensure micro-level accuracy and smoothness even under light loads.

Stainless Steel Linear Guide Blocks

Corrosion-resistant and easy to clean, stainless steel guide blocks are essential for medical, food, and lab equipment.

YH Linear’s stainless blocks ensure long-term performance in harsh or sterile environments.

Aluminum Linear Guide Blocks

Lightweight and fast-moving, aluminum blocks are suitable for high-speed automation systems.

They reduce inertia while maintaining accuracy—perfect for motion-sensitive setups.

Surface Treatments and Coatings

YH Linear applies specialized surface treatments to enhance durability:

Black oxide coating – corrosion resistance

Nickel plating – improved wear protection

Hard chrome finish – extended service life

These finishes make YH Linear blocks resilient under varying conditions.

Load Capacity and Rigidity Considerations

Load capacity depends on the contact angle, number of rolling elements, and preload.

YH Linear’s design ensures:

Uniform load distribution

Minimal deflection

Exceptional stiffness even under shock loads

Our heavy-duty models are capable of carrying thousands of kilograms with consistent precision.

Common Applications of Linear Guide Blocks

CNC milling and cutting machines

3D printers and laser cutters

Industrial robots and automation systems

Medical imaging devices

Semiconductor manufacturing tools

Packaging and labeling machinery

Every YH Linear block is purpose-built for smooth, repeatable performance in these industries.

Installation and Alignment Guidelines

Ensure mounting surfaces are flat and clean.

Align rails precisely before tightening screws.

Tighten gradually in a diagonal sequence.

Move the block manually to check smooth travel.

YH Linear provides detailed installation guides for all models.

Lubrication and Maintenance Practices

Use YH Linear-approved grease or oil for smooth motion.

Re-lubricate after every 1000 hours of use.

Keep seals intact to prevent dirt entry.

Inspect periodically for noise or vibration.

Proper maintenance ensures a lifespan exceeding 10,000 km of travel.

Common Issues and Troubleshooting

| Problem | Cause | Solution |

|---|---|---|

| Noise during motion | Lack of lubrication | Re-lubricate with recommended grease |

| Uneven movement | Misalignment | Reinstall and calibrate |

| Vibration | Excessive preload | Use lighter preload |

| Rust or corrosion | Contaminants | Clean and apply rust-preventive oil |

YH Linear’s support team assists customers with diagnostics and maintenance training.

YH Linear’s Manufacturing and Quality Control

YH Linear ensures precision through:

CNC machining and automated assembly

Surface grinding with ±0.001 mm tolerance

Hardness, wear, and corrosion testing

100% performance inspection before shipment

Our products meet ISO 9001 and RoHS standards.

Customization and OEM Capabilities

We offer custom preload settings, dimensions, and materials to fit specific applications.

YH Linear’s OEM program supports:

Private labeling

Tailored designs

Special coatings and packaging

We collaborate directly with engineers and system integrators for personalized solutions.

Future Innovations in Linear Guide Block Design

YH Linear is developing next-generation designs featuring:

Smart lubrication monitoring sensors

Self-cleaning seal technologies

Ultra-lightweight hybrid materials

AI-assisted predictive wear analysis

These innovations ensure smoother, smarter, and longer-lasting motion systems.

FAQs About Linear Guide Blocks

What does a linear guide block do?

It enables precise, low-friction linear motion along a rail, supporting and guiding mechanical loads.

How long does a YH Linear guide block last?

With proper lubrication, YH Linear blocks can last for several years or millions of motion cycles.

Are linear guide blocks interchangeable?

Not always. For best performance, use blocks and rails from the same series and manufacturer—like YH Linear.

Do YH Linear blocks require lubrication?

Yes, periodic lubrication is essential for maintaining smooth and reliable motion.

Can YH Linear customize guide blocks?

Absolutely. We offer custom preload, size, and material configurations for OEM clients.

What industries use YH Linear guide blocks?

They are used in automation, robotics, CNC machining, and precision medical equipment.

Conclusion

The linear guide block is the foundation of smooth, accurate, and efficient motion control in modern machinery. Whether it’s guiding a robotic arm, positioning a CNC spindle, or stabilizing a laboratory instrument, its performance defines the overall precision of the system.

At YH Linear, we bring unmatched engineering expertise to every linear guide block we produce. With advanced materials, precision machining, and strict quality control, we ensure long-lasting reliability and superior motion accuracy.

When precision matters, YH Linear provides motion solutions you can trust.

Inbound Link Suggestions:

Link to: “Square Linear Guide” (internal)

Link to: “Precision Linear Guide” (internal)

Outbound Link Suggestions:

Link to: YH Linear Official Website