Outline for the Article on “Rail Bearing”

| Section | Subtopics |

|---|---|

| Introduction | What is a rail bearing and why it matters in linear motion systems |

| Definition of Rail Bearing | Concept, terminology, and scope of “rail bearing” |

| How Rail Bearings Work | Mechanics: how bearings interface with rails, load paths, motion characteristics |

| Components of a Rail Bearing System | Rail, carriage/block, rolling elements, seals, return paths |

| Types of Rail Bearings | Ball-type, roller-type, V-groove rail bearings, profile rail bearings |

| Rail Bearings vs Linear Bushings/Slides | Comparison with other linear motion technologies |

| Advantages of Rail Bearings | Low friction, high precision, load capacity, repeatability |

| Common Applications of Rail Bearings | CNC machines, automation, medical devices, material handling |

| Materials and Surface Treatments for Rail Bearings | Stainless vs chrome steel, coatings, hardening |

| Installation Best Practices | Alignment, mounting, preload, lubrication, support structure |

| Maintenance and Lifespan Considerations | Lubrication schedules, contamination control, wear symptoms |

| Selection Criteria for Rail Bearing Systems | Load, speed, accuracy, environment, stroke length |

| Common Failure Modes and Troubleshooting | Misalignment, contamination, insufficient lubrication, shock loads |

| Innovations & Trends in Rail Bearing Technology | Smart sensors, hybrid materials, high-speed rails |

| Summary and Takeaways | Key points to remember when designing with rail bearings |

Rail Bearing

In many precision motion systems, the term rail bearing is used to refer to the bearing assembly that runs along a rail or guideway and supports a carriage or slide block. Essentially, it’s the mechanism by which linear bearings enable smooth, controlled motion along a fixed rail. According to industry sources, linear bearings and rails provide smooth and precise linear motion in machinery and equipment across a wide variety of industries. NSK Automation

In short: when you design a linear motion axis, a rail bearing system is the heart of the movement—how loads, accuracy, and repeatability are achieved. Understanding how rail bearings work, what their components are, and how to select, install, and maintain them is crucial for reliable performance.

Definition of Rail Bearing

A rail bearing refers to the combination of a bearing assembly designed for linear motion (often with rolling elements: balls or rollers) and a rail or guideway on which it moves. Sometimes the term is used somewhat loosely to mean simply the slide block + rail system: the carriage plus the rail forming the linear bearing arrangement.

For example, one vendor lists “rail bearings, including ball bearing carriages and guide rails” in its catalog. mcmaster.com Thus the focus is on linear translation along the rail, supported by the bearing system.

Key points:

The rail is usually hardened steel and ground to high precision.

The carriage or bearing block houses the rolling elements and returns system.

The rolling elements (balls or rollers) reduce friction and support the load.

The system allows accurate, repeatable motion along a guided path.

How Rail Bearings Work

Understanding the workings of a rail bearing system helps in proper design, installation, and maintenance.

Motion & Load‐Path

As the carriage moves along the rail, the rolling elements inside recirculate in raceways. These allow the block to slide with minimal friction, controlled movement, and high repeatability. The rail bearing thus supports the load (vertical, horizontal, and often moment loads) and guides the motion along one direction.

Components Interaction

The rail’s raceway surfaces are ground and hardened so that the rolling elements run smoothly without significant deformation.

The carriage block has internal ball or roller return mechanisms that ensure continuous rolling motion rather than sliding.

Seals or wipers help exclude contaminants and keep lubrication inside.

Mounting surfaces and support structure ensure alignment and rigidity.

Friction Reduction & Precision

Because the motion is rolling, friction is much lower compared to sliding contact. Also, the precision of the rail and carriage alignment leads to high accuracy and repeatability.

Example

One line from a manufacturer: “Linear bearings and rails … are two components of a linear guide system, providing smooth and precise linear motion in machinery and equipment.” NSK Automation This emphasises that rail + bearing = system.

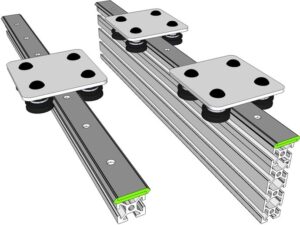

Components of a Rail Bearing System

When you assemble or specify a rail bearing system, you’ll want to consider all major components:

Rail (Guideway): The fixed track, typically hardened and ground.

Carriage / Block / Slide: The moving component which carries loads and houses the rolling elements.

Rolling Elements: Balls or rollers that provide the low‐friction interface.

Return Mechanism / Raceways in Block: Provide looped motion of balls or rollers.

Seals / Wipers: Protect against dust, chips, contamination.

Lubrication Points: Grease or oil feed to maintain performance.

Mounting & Support Structure: The rail is mounted to machine frame; carriage mounts to moving part.

End Caps & Retainers: Provide limits to ball/roller motion and sometimes preload adjustment.

Each of these contributes to system performance—accuracy, load capacity, speed, lifetime.

Types of Rail Bearings

Rail bearing systems come in several types depending on load, precision, speed, and environment.

Ball‐Type Rail Bearings: Use recirculating balls. Good for moderate loads, high precision, high speed. NSK Automation

Roller‐Type Rail Bearings: Use rollers (cylindrical or spherical). Higher rigidity and load capacity, often for heavier systems.

V‐Groove Rail Bearings: Bearings run in V‐groove profiles; e.g., “V/groove rail bearing 1/5-… W1/5zz P6 V‐groove” (see product)

Profile Rail Guides / Square Rails: High precision, multi‐row ball or roller blocks for CNC and automation. lintechmotion.com

Heavy Duty Rail Bearing Systems: For extreme loads and large structures; see “Heavy Duty Linear Guides – Hevi-Rail® Series” as example. PBC Linear

Selecting the correct type depends on the application’s demands for load, moment, speed, environment (contamination, temperature), precision, and stroke length.

Rail Bearings vs Linear Bushings/Slides

It’s helpful to compare rail bearing systems with alternative linear motion options to understand when they are appropriate.

| Feature | Rail Bearing System | Linear Bushings or Plain Slides |

|---|---|---|

| Motion Type | Carriage on rail with rolling elements | Bushing on shaft, sliding contact |

| Friction | Low (rolling) | Higher (sliding) |

| Precision & Repeatability | High | Moderate |

| Load & Moment Capacity | High (especially with roller types) | Varies; sometimes less rigid |

| Sensitivity to Alignment | Sensitive—shaft/rail alignment important | Less sensitive in some cases |

| Speed Capability | Typically higher | Lower due to sliding contact |

| Maintenance & Lubrication Needs | Moderate (seals, lubrication points) | Can be high depending on design |

| Ideal Applications | CNC, automation, precision slides | Simpler movement, less precision required |

Thus, when your application demands precision, repeatability, high speed, and rigid motion, rail bearing systems are often the superior choice.

Advantages of Rail Bearings

Using a rail bearing system brings many advantages to motion design:

High Precision and Repeatability: Because of rolling elements and high quality machining of rails and blocks, positional repeatability can be very tight.

Low Friction and Wear: Rolling motion reduces surface wear and heat generation compared to sliding contact.

High Load & Moment Handling: Especially with multi‐row or roller types, carriage blocks can support large loads and moments.

Speed Capability: Lower friction means higher possible speeds and smoother motion.

Compactness with Rigidity: A properly implemented rail bearing system can provide both compact size and strong stiffness.

Longer Service Life: With correct installation, alignment, and lubrication, rail bearing systems can last a long time.

Better Integration in Automation: Suitable for repeatable, high cycle count industrial motion systems.

These advantages contribute to better machine uptime, less maintenance, higher throughput, and greater precision.

Common Applications of Rail Bearings

Rail bearing systems are used across many industrial applications:

CNC Machining & Milling Centers: Linear motion axes rely on rail bearing systems for accurate table or spindle movement. NSK Automation+1

Robotic Automation: Linear axes, gantries, pick-and‐place systems often use rail bearing systems for smooth, precise motion.

Medical & Laboratory Equipment: Devices needing repeatable precise linear movement often use miniature rail bearing systems.

Material Handling & Packaging: Conveyors, slides, and guided motions benefit from rail bearing systems.

Semiconductor and Electronics Manufacturing: Cleanroom compatible rail bearing systems provide controlled motion in sensitive environments.

Heavy Machinery & Construction Equipment: Heavy-duty rail bearing systems support large loads and long travel lengths. (e.g., Hevi-Rail) PBC Linear

In any application where straight-line, high precision, and repeatability matter, rail bearing systems are a key component.

Materials and Surface Treatments for Rail Bearings

Choosing materials and proper treatment is critical to performance:

Rail Material: Typically hardened chrome steel or stainless steel (for corrosion resistance).

Carriage Block Material: Usually matching hardened steel, with precision ground surfaces.

Rolling Elements: Steel balls, hardened rollers; in some premium designs ceramic rollers/balls.

Surface Treatments: Hardening (case or through), plating or coatings for corrosion resistance, DLC (diamond-like carbon), or PTFE overlays for low friction.

Seals/Wipers: Elastomer or metal seals to exclude contamination.

The right material choice affects lifetime, precision, environment compatibility (dust, coolant, tolerances), temperature range, and cost.

Installation Best Practices

Proper installation is vital to making a rail bearing system perform its best:

Ensure Rigidity and Support: The machine frame or base must be flat, stable, and properly supported.

Align the Rail(s) Precisely: Parallelism and flatness of rails are critical. Misalignment leads to uneven load on rolling elements and premature wear.

Mounting Surface Preparation: Remove burrs, chips, clean surfaces; ensure correct torque tightening of bolts.

Preload or Clearance Adjustment: Some systems need preload settings to remove play—follow manufacturer specs.

Lubrication Before First Use: Even sealed systems may require initial lubrication.

Protect from Contamination: Install wipers/shields where chips, dust or debris may enter.

Initial Movement & Break-in: Run the axis gently at first, check for smooth motion, listen and feel for any binding or irregularities.

Maintenance and Lifespan Considerations

To maximize lifespan of a rail bearing system:

Regular Inspection: Listen for noise, inspect seals, check carriage movement, inspect rail for wear or damage.

Lubrication: Refresh lubricant according to manufacturer interval and application conditions.

Monitoring Contamination: Chips, coolant, or dust are enemies of precision rails—clean regularly and use protective covers.

Check for Misalignment: Movement should remain smooth; binding or uneven resistance indicates alignment issues.

Replace When Worn: Signs of pitting or metal flakes mean the system is likely near end life. Rolling contact fatigue is a known failure mode. 维基百科

Keep Shock Loads Low: Avoid excessive sudden loads; heavy shocks reduce life dramatically.

By following good practices, rail bearing systems can serve reliably for many years, reducing downtime and maintenance cost.

Selection Criteria for Rail Bearing Systems

When selecting a rail bearing system, consider:

Load (Radial, Axial, Moment): Choose size and type that handles worst case loads plus safety margin.

Speed & Travel Length: Longer travel or high speed may require specific rail/block series.

Precision/Repeatability Requirements: Tighter tolerances → higher grade rail and block quality.

Environment: Presence of dust, wet/coolant, temperature extremes—choose proper sealing and materials.

Stroke & Mounting Structure: Ensure rail length, mounting space, and stiffness of machine structure are adequate.

Maintenance Access & Lifetime: Consider ease of servicing, expected life, cost of replacement.

Budget & Brand/Quality: Higher quality rails cost more but often offer lower downtime, better precision, longer life.

For instance, a manufacturer emphasises that selection factors include load capacity, precision, speed, support arrangements, and environment. NSK Automation

Common Failure Modes and Troubleshooting

Despite good design, problems can occur. Common issues and how to address them:

Binding or Rough Movement: Likely caused by misalignment, debris, insufficient lubrication. Fix: clean, align, relubricate.

Noise or Vibration: Could be chipped balls/rollers, worn raceways, or contamination. Inspect and replace worn parts.

Excessive Wear or Scoring on Rail: Often due to debris, inadequate lubrication or misalignment. Clean, improve sealing, retry alignment.

Play or Loose Movement: Preload may have relaxed; check clearance settings or adjust.

Shortened Life (Fatigue, Cracks): Rolling contact fatigue may show pitting or flaking. Replace and review design for overload or shock. 维基百科

Corrosion: In harsh environments, rail or bearings may corrode. Use stainless or coated systems, improve sealing.

Addressing these issues promptly ensures longer life and consistent precision.

Innovations & Trends in Rail Bearing Technology

Rail bearing systems continue evolving to meet higher performance demands:

Hybrid Materials & Coatings: Use of ceramic rolling elements or DLC coatings for reduced wear and longer life.

Integrated Sensors: Monitoring preload, temperature, vibration for predictive maintenance.

Heavy-Duty Rail Systems: Solutions like the Hevi-Rail® series for extreme loads and rugged conditions. PBC Linear

Compact/Low-Profile Designs: For lightweight, high-speed machines and compact automation.

Eco-friendly Lubricants & Maintenance-Free Systems: Reduce downtime and environmental impact.

These trends make rail bearing systems more robust, smarter, and lower maintenance.

Summary and Takeaways

When choosing and designing with rail bearing systems, keep these key points in mind:

Rail bearings deliver high precision, low friction, and repeatability—ideal for linear motion systems.

They consist of a rail + carriage + rolling elements; quality of each dictates performance.

Select type (ball vs roller), size, precision, environment compatibility based on your application.

Proper installation and alignment are as important as component quality.

Maintenance, lubrication, and contamination control significantly affect lifespan.

Monitor for common failure modes (misalignment, wear, fatigue) and take proactive action.

Stay aware of emerging technologies and trends that could improve performance and cost-effectiveness.

For any linear motion system striving for precision, durability, and reliability, a well-specified rail bearing system is a critical foundation.

Suggested Inbound Links for Your Brand Page (if applicable):

Link to “Rail Bearing Systems” product page

Link to “Linear Rails and Slides” overview article on your site

Link to “Installation & Maintenance Guide” page

Suggested Outbound Links:

Technical explanation on linear bearings and rails: NSK Automation – Linear Bearings and Rails NSK Automation

Heavy duty linear rail guide example: PBC Linear Hevi-Rail® Series PBC Linear

Catalog for rail bearings: McMaster-Carr Rail Bearings mcmaster.com