Outline for What is a Linear Bearing

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Linear Bearings | Importance in modern industry, overview |

| What is a Linear Bearing? | Definition, function, and purpose |

| History and Development of Linear Bearings | Early designs, modern innovations |

| Core Components of Linear Bearings | Housing, rolling elements, shaft/rail |

| How Do Linear Bearings Work? | Principle of motion, rolling vs sliding |

| Different Types of Linear Bearings | Ball bearings, roller bearings, plain bearings |

| Ball Type Linear Bearings | Features, advantages, applications |

| Roller Type Linear Bearings | Load handling, heavy-duty uses |

| Plain Linear Bearings | Simplicity, low-cost applications |

| Linear Bearing vs Linear Guide | Structural and functional differences |

| Advantages of Linear Bearings | Efficiency, low friction, long lifespan |

| Disadvantages of Linear Bearings | Cost, contamination issues |

| Materials Used in Linear Bearings | Steel, ceramic, polymer |

| Lubrication and Maintenance | Grease, oil, self-lubricating designs |

| Common Applications of Linear Bearings | CNC, robotics, automotive |

| Linear Bearings in CNC Machines | Precision movement in milling and cutting |

| Linear Bearings in Robotics | Automation, pick-and-place systems |

| Medical Applications of Linear Bearings | Surgical robotics, imaging systems |

| Aerospace Use of Linear Bearings | Flight control, navigation |

| Challenges in Using Linear Bearings | Wear, alignment, environmental factors |

| Linear Bearing Selection Guide | Load, speed, environment, precision |

| Installation Best Practices | Alignment, preload, mounting tips |

| Troubleshooting Common Issues | Noise, wear, misalignment |

| Future Trends in Linear Bearing Technology | Smart sensors, IoT integration |

| Conclusion | Summary of importance |

| FAQs | Commonly asked questions |

Introduction to Linear Bearings

The industrial world thrives on accuracy, efficiency, and smooth operation. At the heart of many precision systems lies a small yet powerful component—the linear bearing. Whether in a CNC machine shaping intricate parts, a robotic arm handling delicate movements, or a medical scanner requiring flawless positioning, linear bearings play a crucial role.

They provide low-friction, straight-line motion, ensuring that heavy loads move effortlessly while maintaining accuracy. Unlike crude sliding mechanisms, linear bearings rely on rolling elements like balls or rollers to reduce resistance. This seemingly simple principle has transformed manufacturing, automation, healthcare, and even aerospace industries.

In a world moving toward automation and artificial intelligence, linear bearings are becoming even more important. Their ability to deliver repeatable, smooth, and efficient motion is what makes them indispensable in modern engineering.

What is a Linear Bearing?

A linear bearing is a mechanical device designed to allow controlled linear motion with minimal friction. It guides and supports a moving part, typically along a shaft or rail, while maintaining stability and precision.

Imagine a sliding drawer: it moves in and out along a straight path. Replace its sliding tracks with rolling balls or rollers, and you get the fundamental working principle of a linear bearing. By reducing surface contact through rolling motion, linear bearings ensure efficiency, durability, and accuracy.

Linear bearings are often paired with linear shafts or rails, and depending on design, they can support both light and heavy loads. Their ability to handle repetitive, high-speed, and accurate movements makes them essential in industries where micron-level precision is non-negotiable.

So, when asking “what is a linear bearing?”, the simplest answer is: it’s a component that ensures smooth, straight-line movement with reduced friction—an unsung hero of modern engineering.

History and Development of Linear Bearings

The history of linear bearings is a story of innovation driven by necessity.

Ancient Beginnings: Thousands of years ago, civilizations used wooden rollers to move heavy stones. The Egyptian pyramids are often cited as examples of early linear motion systems.

Industrial Revolution: The 18th and 19th centuries brought metal screws, gears, and sliding mechanisms. While effective, these suffered from wear and energy loss due to friction.

Birth of Bearings: In the 19th century, ball bearings revolutionized rotational systems. Engineers soon realized the same principle could apply to linear motion.

20th Century Precision: With the rise of machine tools, linear bearings became essential. By mid-20th century, recirculating ball linear bearings enabled CNC machining and high-speed automation.

Modern Era: Today, linear bearings come in many forms—ball, roller, plain, and hybrid designs. They are lighter, stronger, quieter, and sometimes even self-lubricating. The latest trend integrates smart sensors for predictive maintenance, paving the way for Industry 4.0.

From logs to IoT-enabled bearings, the journey of linear bearings highlights their enduring role in engineering progress.

Core Components of Linear Bearings

Every linear bearing consists of carefully designed parts working together for optimal performance.

Housing: The outer structure that holds everything in place, often made of steel or aluminum.

Rolling Elements: Balls or rollers that move between surfaces, reducing friction.

Shaft or Rail: The track that guides the motion. Precision-ground rails ensure stability.

Retainer/Cage: Maintains spacing between rolling elements to prevent collisions.

Seals: Protect against dust, debris, and moisture.

Lubrication Ports: Ensure smooth operation and long life.

These elements may seem simple individually, but together they create a precision system capable of handling high loads with flawless accuracy.

How Do Linear Bearings Work?

Linear bearings work on the principle of rolling motion versus sliding motion.

When a shaft or rail is paired with a bearing containing rolling elements:

The rolling elements (balls or rollers) move between the shaft and the bearing housing.

Instead of sliding across surfaces, the balls roll, which reduces friction drastically.

This rolling action allows smooth, efficient, and repeatable movement.

Some linear bearings are recirculating (balls move in continuous loops), while others are non-recirculating (balls move in limited ranges). Regardless of type, the result is the same: controlled, straight-line motion with reduced resistance.

This is why industries choose linear bearings over traditional sliding systems—less heat, less wear, and more accuracy.

Different Types of Linear Bearings

Linear bearings are not one-size-fits-all. They come in different types, each suited for specific applications:

Ball Linear Bearings – Use recirculating ball elements for smooth, precise movement.

Roller Linear Bearings – Use cylindrical rollers to handle heavier loads.

Plain Linear Bearings – Rely on sliding surfaces, often made of polymer or bronze.

Magnetic & Air Bearings – Advanced options for ultra-smooth, frictionless motion.

Each type balances cost, load capacity, friction, and precision, depending on the industry’s needs.

Ball Type Linear Bearings

Ball linear bearings are the most common. They use recirculating ball bearings between the shaft and housing, ensuring low friction and high precision.

Advantages:

Extremely smooth motion

High accuracy

Easy to maintain

Applications:

CNC machines

3D printers

Robotics

Ball type linear bearings are the go-to solution for industries demanding repeatable accuracy and low resistance.

Roller Type Linear Bearings

Roller linear bearings replace balls with cylindrical rollers. This increases the contact surface area, allowing them to handle heavier loads.

Advantages:

Higher load capacity than ball bearings

Better rigidity

Long service life

Applications:

Heavy-duty automation

Aerospace equipment

Automotive production lines

Roller bearings are the champions of load-bearing and durability.

Plain Linear Bearings

Plain linear bearings, also called bushings, don’t use rolling elements. Instead, they rely on low-friction materials like bronze, PTFE, or polymers.

Advantages:

Low cost

Compact design

Resistant to dust and dirt

Applications:

Office equipment

Packaging machines

Environments where lubrication is difficult

Though not as precise as ball or roller types, plain bearings are excellent for simple, cost-effective motion systems.

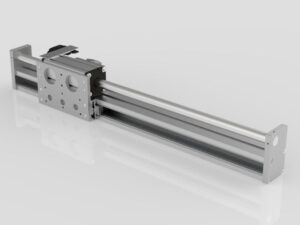

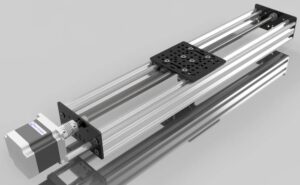

Linear Bearing vs Linear Guide

While they sound similar, linear bearings and linear guides are not identical.

Linear Bearings: Typically ride on a round shaft, offering flexibility and ease of installation.

Linear Guides: Move along a precision rail with block carriages, offering higher rigidity and accuracy.

Linear bearings excel in lighter, flexible setups, while linear guides dominate in high-precision, heavy-duty applications.

Advantages of Linear Bearings

Low Friction: Rolling motion reduces energy loss.

High Accuracy: Suitable for micron-level applications.

Durability: Can withstand long-term, repetitive use.

Efficiency: Require less power to operate machinery.

Versatility: Available in many types and materials.

Disadvantages of Linear Bearings

Higher Cost: Especially for high-precision models.

Contamination Risk: Dust and debris can disrupt rolling motion.

Lubrication Needs: Require proper maintenance.

Despite these challenges, their benefits far outweigh the drawbacks, especially in precision industries.

Materials Used in Linear Bearings

The choice of material affects performance, durability, and cost.

Steel: High strength and durability.

Ceramics: Lightweight, corrosion-resistant.

Polymers: Cost-effective, self-lubricating.

Lubrication and Maintenance

Proper lubrication is vital. Bearings can use:

Grease: Long-lasting, ideal for sealed systems.

Oil: Better for high-speed applications.

Self-lubricating Materials: Reduce maintenance needs.

Regular inspection and lubrication ensure long service life.

Common Applications of Linear Bearings

CNC Machines: Precision cutting and shaping.

Robotics: Smooth and repeatable motion.

Medical Devices: Imaging and surgical tools.

Aerospace: Navigation and actuation systems.

Automotive: Production line automation.

Challenges in Using Linear Bearings

Wear and Tear from constant use.

Alignment Issues causing inefficiency.

Environmental Contamination affecting rolling elements.

Solutions include protective seals, precision installation, and smart monitoring systems.

Linear Bearing Selection Guide

When choosing a linear bearing, consider:

Load requirements

Speed and acceleration

Operating environment

Precision needs

Maintenance availability

Selecting the right bearing ensures longer life and better performance.

Installation Best Practices

Ensure precise alignment.

Apply correct preload to reduce backlash.

Secure bearings properly to prevent vibration.

Use clean, lubricated rails or shafts.

Good installation is half the battle won for smooth operation.

Troubleshooting Common Issues

Noise: May indicate lack of lubrication.

Wear Marks: Suggest contamination or misalignment.

Sticking/Binding: Often due to improper preload.

Quick maintenance checks can prevent costly downtime.

Future Trends in Linear Bearing Technology

The future is exciting for linear bearings:

Smart Bearings: IoT integration for real-time monitoring.

Self-Healing Materials: Extending lifespan.

Lightweight Designs: Using composites and ceramics.

Sustainable Manufacturing: Eco-friendly materials and lubricants.

Linear bearings are evolving to meet the demands of automation, AI, and Industry 4.0.

Conclusion

So, what is a linear bearing? It is more than just a mechanical part—it’s the foundation of modern precision motion. From heavy industrial machines to delicate medical equipment, linear bearings ensure smooth, accurate, and efficient linear motion.

By reducing friction and enabling precise control, they have become indispensable in automation, robotics, aerospace, and beyond. As industries push boundaries, linear bearings will continue evolving, driving innovation and efficiency into the future.

FAQs

What is the purpose of a linear bearing?

It enables smooth, straight-line motion with minimal friction.

What are the main types of linear bearings?

Ball, roller, plain, and advanced options like magnetic and air bearings.

Do linear bearings require lubrication?

Yes, lubrication is crucial for long life and efficient performance.

What industries use linear bearings the most?

CNC machining, robotics, aerospace, automotive, and medical equipment.

How do I choose the right linear bearing?

Consider load, speed, environment, precision, and maintenance needs.

What is the difference between linear bearings and linear guides?

Linear bearings ride on shafts for flexible setups, while linear guides use rails for higher precision and rigidity.

Inbound Link Suggestions:

Link to an article about Ball Screw Linear Guide

Link to a guide on CNC Machine Components

Outbound Link Suggestions: