Outline for Linear Guide Rail

| Main Topic | Sub-Topics / Sub-Headings |

|---|---|

| Introduction | What is a Linear Guide Rail? |

| Linear Guide Rail | Core Definition and Function |

| History of Linear Guide Rail | Evolution from Early Systems to Modern Designs |

| Components of Linear Guide Rail | Rails, Blocks, Bearings, and Accessories |

| Types of Linear Guide Rail | Roller Type, Ball Type, Flat Guide, Profiled Guide |

| Linear Guide Rail vs. Linear Shaft | Key Differences and Applications |

| Advantages of Linear Guide Rail | Precision, Durability, and Smooth Movement |

| Applications in Manufacturing | CNC Machines, Robotics, Conveyors |

| Linear Guide Rail in Automation | Impact on Industrial Automation and Robotics |

| Medical Equipment Applications | Use in Imaging, Surgery, and Laboratory Systems |

| Aerospace Applications | High-Precision Needs in Aviation and Space Tech |

| Factors to Consider Before Buying | Load, Speed, Environment, and Cost |

| Installation of Linear Guide Rail | Step-by-Step Guide for Proper Setup |

| Maintenance Tips | Lubrication, Cleaning, and Alignment |

| Common Mistakes in Using Guide Rails | Overloading, Misalignment, Neglecting Maintenance |

| How to Improve Guide Rail Performance | Best Practices and Upgrades |

| Cost of Linear Guide Rail | Price Ranges and Factors Affecting Cost |

| Top Global Manufacturers | THK, Hiwin, NSK, Bosch Rexroth |

| Comparing Brands | Which Brand Offers Best Value? |

| Linear Guide Rail in 3D Printing | Smooth and Accurate Print Head Movement |

| Future of Linear Guide Rail | Smart Sensors, IoT Integration, and AI Monitoring |

| Eco-Friendly Guide Rails | Sustainability and Energy Efficiency |

| DIY Linear Guide Rail Projects | For Hobbyists and Small Businesses |

| Linear Guide Rail Troubleshooting | Fixing Noise, Vibration, and Jamming |

| Buying Guide Checklist | Final Thoughts Before Purchasing |

| Conclusion | Why Linear Guide Rail is Essential in Modern Engineering |

| FAQs | Answering the Most Common Questions |

Introduction

In the world of precision engineering, even the smallest component can make the biggest difference. Machines, robots, and automation systems require accuracy down to the micron. That level of precision isn’t possible without a linear guide rail.

From CNC machining and 3D printing to aerospace and medical equipment, linear guide rails quietly power modern innovation. Their role is simple yet indispensable: providing smooth, controlled, and highly accurate motion along a straight path. Without them, manufacturing lines would stall, robotics would wobble, and critical medical devices might lose accuracy.

This comprehensive guide will cover everything you need to know about linear guide rails—what they are, how they work, where they’re used, and what to consider before buying one. Let’s uncover why this mechanical marvel has become a cornerstone of today’s high-tech world.

Linear Guide Rail

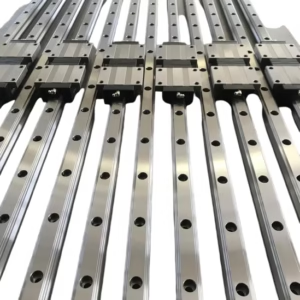

A linear guide rail is a mechanical system designed to move loads along a straight path with minimal friction. It consists of two primary parts:

Rail – a precision-ground steel track that serves as the guide.

Carriage or block – a sliding component that houses ball bearings or rollers.

The carriage moves smoothly along the rail, offering stability, rigidity, and accuracy. Unlike sliding plain bearings, linear guide rails reduce resistance significantly, enabling high-speed, precise motion even under heavy loads.

They are widely used in CNC machines, robotic arms, semiconductor equipment, and even medical scanners, proving their versatility across industries.

History of Linear Guide Rail

The concept of guided motion dates back centuries. Ancient civilizations used wooden or stone grooves to move carts or tools. However, true precision motion systems didn’t emerge until the Industrial Revolution, when metalworking and machine building demanded greater accuracy.

Early designs used sliding ways, which created friction and wore out quickly.

20th century innovations introduced ball bearings, dramatically reducing resistance.

Late 1900s brought the development of profiled linear guide rails, which offered higher stiffness, longer life, and compact sizes.

Today, thanks to advancements in metallurgy, coating technology, and precision grinding, linear guide rails have become more durable, corrosion-resistant, and adaptable to harsh environments.

Components of Linear Guide Rail

To understand its function, let’s break down the key components:

Rail: The fixed part, made of hardened steel, provides the track.

Carriage/Block: Moves along the rail, holding the rolling elements.

Ball Bearings or Rollers: Reduce friction by enabling rolling motion instead of sliding.

End Caps & Seals: Prevent dirt, dust, and contaminants from damaging the system.

Lubrication System: Keeps movement smooth and reduces wear.

These parts work in harmony to ensure precision motion while handling loads ranging from grams to several tons.

Types of Linear Guide Rail

Linear guide rails come in different types, each tailored for specific needs:

Ball Type: Uses steel balls to provide smooth motion. Common in CNC and 3D printing.

Roller Type: Uses cylindrical rollers for higher rigidity and load capacity. Preferred in heavy-duty industrial machines.

Flat Guide: Traditional sliding type, offering low cost but higher friction.

Profiled Guide: Modern design with improved stiffness and compact structure.

Choosing the right type depends on speed, load, precision, and environment.

Linear Guide Rail vs. Linear Shaft

Many beginners confuse linear guide rails with linear shafts. While both provide straight-line motion, their designs and uses differ:

| Feature | Linear Guide Rail | Linear Shaft |

|---|---|---|

| Load Capacity | High | Moderate |

| Precision | Very High | Medium |

| Rigidity | Excellent | Limited |

| Applications | CNC, robotics, aerospace | Light automation, DIY projects |

If your project demands high precision and durability, guide rails are the clear choice.

Advantages of Linear Guide Rail

The benefits are numerous:

High Precision: Maintains accuracy even under heavy loads.

Durability: Long service life with proper maintenance.

Smooth Movement: Minimal friction reduces wear and improves efficiency.

Compact Design: Saves space compared to older motion systems.

Versatility: Works across industries from medical to manufacturing.

These advantages make them a must-have in modern machine design.

Applications in Manufacturing

In manufacturing, linear guide rails are everywhere. CNC machines rely on them for accurate tool positioning. Robotics systems use them to ensure stable and repeatable movements. Automated conveyors, laser cutters, and packaging machines also depend on these rails for uninterrupted motion.

Their precision not only boosts productivity but also reduces energy consumption, as less effort is wasted overcoming friction.

Linear Guide Rail in Automation

Automation thrives on reliability and repeatability. Linear guide rails allow robotic arms, pick-and-place systems, and automated inspection machines to move with pinpoint accuracy.

With the rise of Industry 4.0, smart factories demand components that can handle high-speed cycles without downtime. Linear guide rails, when paired with IoT-enabled sensors, provide real-time performance data, ensuring predictive maintenance and zero unexpected breakdowns.

Medical Equipment Applications

In healthcare, precision isn’t optional—it’s life-saving. Linear guide rails power MRI scanners, X-ray machines, surgical robots, and laboratory automation devices.

They ensure that imaging machines capture exact slices of data, while robotic surgery systems perform delicate operations with micrometer precision. Without them, medical technology wouldn’t achieve the reliability we take for granted today.

Aerospace Applications

In aerospace, weight, vibration resistance, and accuracy are critical. Linear guide rails are used in aircraft assembly lines, satellite manufacturing, and even test rigs for jet engines. Their ability to handle extreme conditions—temperature fluctuations, heavy loads, and constant vibration—makes them ideal for aviation and space applications.

Factors to Consider Before Buying

Choosing the right linear guide rail requires evaluating:

Load Capacity: Can it support the intended weight?

Precision: Does the application need micrometer accuracy?

Speed: Will the system move slowly or at high velocity?

Environment: Is it exposed to dust, moisture, or chemicals?

Cost vs. Performance: Does it balance budget with functionality?

Selecting carefully ensures long-term reliability and cost savings.

Installation of Linear Guide Rail

Proper installation is key to performance:

Prepare the mounting surface – It must be flat and clean.

Align the rail – Precision alignment avoids uneven wear.

Secure with bolts – Tighten gradually to prevent distortion.

Install the carriage – Ensure smooth movement along the rail.

Lubricate – Apply recommended grease or oil.

Mistakes in installation can reduce lifespan dramatically.

Maintenance Tips

Even the toughest guide rails need care:

Lubrication: Regularly grease or oil to prevent friction.

Cleaning: Wipe off dust, chips, and dirt.

Check Alignment: Misalignment causes uneven wear.

Replace Worn Parts: Don’t delay if seals or blocks show damage.

With proper maintenance, rails can last decades.

Common Mistakes in Using Guide Rails

Some errors are more common than others:

Overloading beyond rated capacity.

Ignoring lubrication schedules.

Installing on uneven surfaces.

Exposing rails to corrosive chemicals without protection.

Avoiding these pitfalls maximizes efficiency and lifespan.

How to Improve Guide Rail Performance

Performance can be boosted by:

Using high-quality lubricants.

Installing vibration dampers in high-speed systems.

Upgrading to roller types for heavy loads.

Adding protective covers in dusty environments.

Cost of Linear Guide Rail

Linear guide rails vary widely in cost:

Entry-level small rails: $50–$200

Industrial-grade systems: $500–$5,000

Custom aerospace/medical rails: $10,000+

Factors like brand, size, load rating, and material affect price.

Top Global Manufacturers

Some of the most trusted names include:

THK – Japanese precision engineering leader.

Hiwin – Taiwanese brand known for affordability and quality.

NSK – Renowned for durability and innovation.

Bosch Rexroth – German engineering excellence.

Each brand caters to different budgets and needs.

Comparing Brands

THK: Best for aerospace and robotics.

Hiwin: Great balance of cost and quality.

NSK: Ideal for long-life, high-durability needs.

Bosch Rexroth: Top choice for automation and heavy machinery.

Linear Guide Rail in 3D Printing

3D printers demand smooth, vibration-free motion. Linear guide rails allow print heads and beds to move with high precision, resulting in cleaner layers and better-quality prints.

For hobbyists and professionals, upgrading from rods to guide rails can dramatically improve print results.

Future of Linear Guide Rail

The future is bright with smart guide rails integrating:

IoT sensors for real-time monitoring.

AI diagnostics predicting failures before they occur.

Eco-friendly materials reducing carbon footprint.

This evolution will make linear guide rails even more reliable, sustainable, and intelligent.

Eco-Friendly Guide Rails

Sustainability is a growing concern. Manufacturers now use low-friction coatings, energy-efficient production methods, and recyclable materials to make eco-conscious rails.

These innovations not only reduce waste but also cut down energy consumption in factories.

DIY Linear Guide Rail Projects

For hobbyists, linear guide rails can be used in:

DIY CNC machines.

Custom 3D printers.

Home automation systems.

Camera sliders for videography.

Affordable rails make it easier than ever to experiment with precision engineering at home.

Linear Guide Rail Troubleshooting

Common issues and quick fixes:

Noise or vibration: Check lubrication and alignment.

Jamming: Inspect for debris in the rail.

Uneven wear: Verify load distribution.

Corrosion: Apply protective coatings or switch to stainless steel.

Buying Guide Checklist

Before purchasing, ensure the rail meets these criteria:

Correct load rating.

Suitable length and stroke.

High enough precision grade.

Reliable brand reputation.

Compatibility with existing systems.

Conclusion

The linear guide rail may look simple, but its impact is massive. It powers everything from medical scanners to aerospace assembly lines. By ensuring smooth, precise, and durable motion, it enables industries to achieve higher productivity and accuracy.

Whether you’re an engineer, manufacturer, or hobbyist, choosing the right guide rail is an investment in reliability and performance. With future innovations on the horizon, linear guide rails will remain at the heart of automation and engineering for years to come.

FAQs

What is a linear guide rail used for?

It provides smooth, accurate motion in machines like CNC systems, robotics, and medical devices.

How long does a linear guide rail last?

With proper care, it can last 10–20 years, depending on usage.

Can I use a linear shaft instead of a guide rail?

Yes, but guide rails offer higher precision and rigidity, especially under heavy loads.

What’s the difference between ball and roller types?

Ball types are smoother and faster, while roller types handle higher loads.

Do linear guide rails require lubrication?

Yes, lubrication is essential to reduce wear and maintain performance.

Which brand makes the best linear guide rails?

THK, Hiwin, NSK, and Bosch Rexroth are among the top global manufacturers.

Suggested Inbound Links

Link to an article on CNC machining basics.

Link to a guide on robotics automation systems.

Link to a blog about 3D printing upgrades.