Introduction

When designing machines or automation systems, one of the components that quietly makes a huge difference is the use of linear guides and rails. These components may seem simple—a rail, a carriage, maybe some bearings—but in fact they underpin precise motion, long-life performance, minimal friction and high accuracy. In this article I’ll walk you through how linear guides and rails work, their history, types, selection criteria, installation, maintenance, common pitfalls, applications and future directions. I’ll draw on both manufacturer data and first-hand experience in machine design to give you an optimistic yet realistic view. Whether you’re an engineer, a designer, or someone curious about motion systems, you’ll get solid insights.

What are Linear Guides and Rails

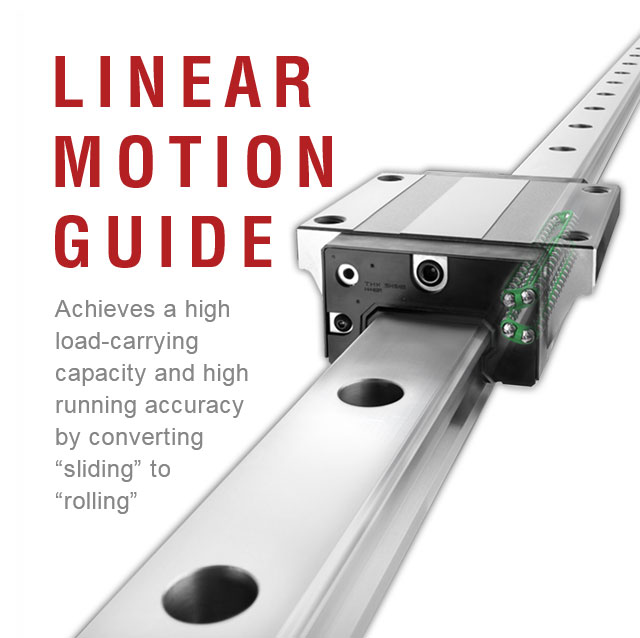

At their simplest, linear guides and rails are mechanical components that allow a part (a carriage, slider, block) to move in a straight line (linear motion) along a fixed track (the rail) with controlled constraints and minimal friction. The “guide” part is the sliding or rolling element (block) and the “rail” is the fixed track upon which the block travels.

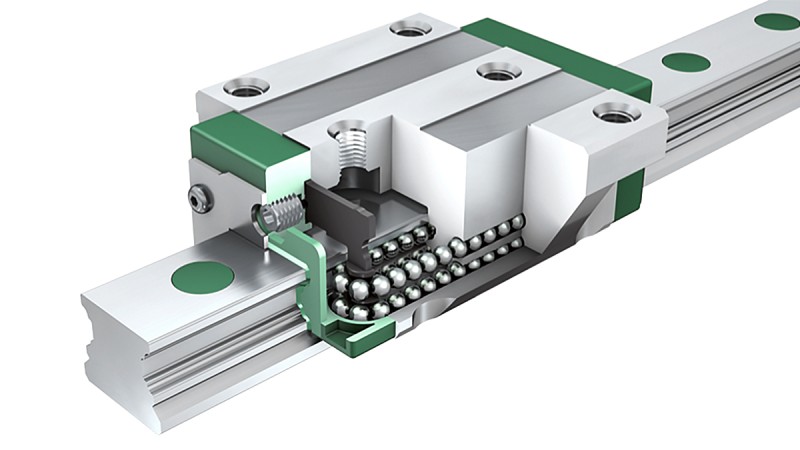

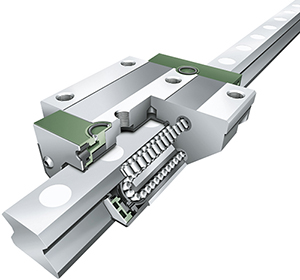

In more specific terms: many manufacturers describe a linear guide (sometimes called a “linear motion guide”, “linear motion guideway”, or “LM Guide” in Japanese parlance) as comprising a mobile carriage (block) plus a hardened rail with raceways, and rolling elements (balls or rollers) inside the carriage that recirculate as the block travels. thk.com+1

Here’s a simplified breakdown:

Rail: hardened steel track, fixed to the machine base.

Carriage/Block: rides on the rail, contains rolling elements (balls or rollers) that allow smooth motion.

Rolling elements: provide low-friction motion by rolling rather than sliding.

Raceways/paths: grooves in the rail and the carriage that define the motion path and load bearings.

Mounting and fixation: the rail is bolted down, the block travels along it.

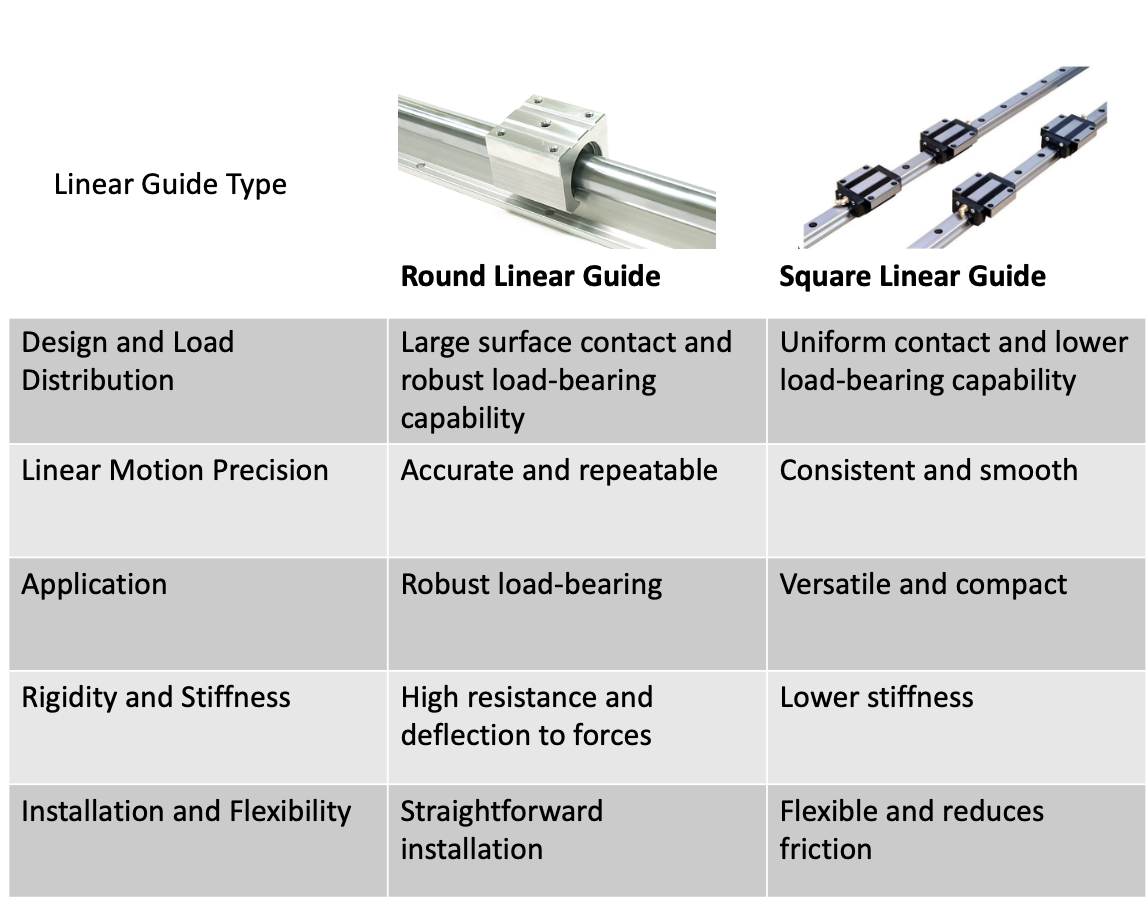

Why this matters: compared to simple sliding bearings (plain bushings), linear guides offer far lower friction, higher load capacity (especially moment loads), better precision, and often longer service life. For machines where accuracy, repeatability and speed matter—such as CNC machines, robotics, measuring equipment—they are nearly indispensable.

So in one sentence: linear guides and rails allow smooth, precise, repeatable linear motion with low friction and high load capacity.

History and Evolution of Linear Guides and Rails

The story of linear guides and rails is one of incremental improvements in bearing and motion technology. It reveals how a simple concept—rolling contact instead of sliding contact—evolved into the high-precision systems we rely on today.

Key milestones:

In 1944 in the U.S., the ball bushing was developed. This was a linear motion rolling guide: balls circulated between a cylindrical shaft and sleeve nut. But load capacity was low and clearance issues were present. thk.com

A ball spline was then developed: arc-shaped raceways allowed surface contact instead of point contact between balls and raceways, improving load capacity and eliminating nut rotation on the shaft. thk.com

The founder of THK Co., Ltd. (Japan) developed the angular ball spline in 1971; then in 1972 the first “linear motion ball guide” (Model LSR) was introduced: a fixed base rail + carriage on a hardened shaft, eliminating deflection problems. thk.com

By 1973-75 THK had developed the combined rail and block structure (LM rail + LM block) which is the form many guided linear rails use today. thk.com

From there: the technology expanded to include roller-type recirculating guides, specialized coatings, lubrication units, longer rails, heavier loads, self-alignment systems and variants for dirty environments. For example, manufacturers like Rollon emphasise hardened raceways, self-alignment and dirty-environment capability. rollon.com

Thus the evolution: sliding bushings → ball bushings → ball splines → linear motion ball guide (LM Guide) → modern profiled rails and blocks. The modern era is defined by high load, high accuracy, long travel, self-alignment, sealed units, and minimal maintenance.

Key Components and How They Work

Understanding the architecture helps when you need to select or specify these components. Let’s break down the components of linear guides and rails and how they function.

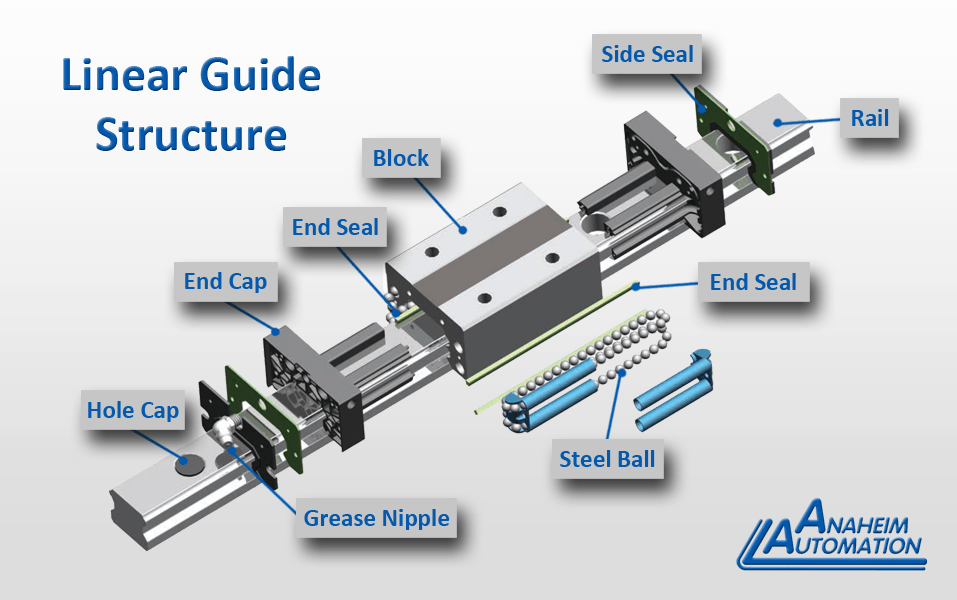

Rail

The rail is the fixed element affixed to the machine structure. It features hardened steel raceways (either V-groove, flat, U-shaped or other profiles) which match the carriage’s raceways. The rail must be rigid, straight, and properly mounted to avoid misalignment, deflection or poor performance. For example, some rails are cold drawn carbon steel with induction-hardened and ground raceways. rollon.com+1

Carriage or Block

The carriage (also called the slider or block) rides on the rail. Inside the carriage are rolling elements (balls or rollers) that recirculate through the block as it travels. The carriage may also have features like seals, wipers, lubrication ports or maintenance units. The carriage may carry the load (either above the rail or underneath) and transmit forces and moments.

Rolling Elements

These are the balls (in ball-type guides) or rollers/needles (in roller type guides). They are the actual bearing elements that allow motion. Because they roll rather than slide, friction is lower. For instance, the recirculating ball bearing mechanism inside the LM Guide allows infinite travel (assuming infinite rail) because the balls loop. thk.com

Raceways and Contact Geometry

The geometry of the contact between rail and carriage determines load capacity, rigidity, moment load handling, accuracy and stiffness. For example, some guides use “gothic arch” raceways (see the Redi-Rail series) which allow better preload and accuracy. PBC Linear

Mounting and Fixation

Proper mounting is essential: the rail must sit on a flat, rigid base; bolts must be tightened to correct torque; shims or surface preparation may be needed. Misalignment or poor mounting can ruin the precision and lifespan of the guide.

Seals, Lubrication, Accessories

Modern linear guides often integrate seals to protect against dust, chips or coolant; lubrication units to deliver grease automatically; and variations for special environments (corrosion resistance, high temperature, vacuum). For example, the drylin® series by igus offers self-lubricating guides that operate without oil or grease, ideal for dirty or hygiene-sensitive environments. igus.com

Why Use Linear Guides and Rails? (Benefits & Advantages)

Choosing linear guides and rails over simpler bearing systems (e.g., plain linear bushings, rod bearings or even slides) offers several compelling reasons. Here are the key benefits.

Precision and Repeatability

Because the rolling elements constrain motion precisely and the raceways are hardened and ground, linear guides offer high accuracy and repeatability. This is critical in machine tools, CNC systems, robotics and precision positioning. As per NSK: “smooth, quiet, reliable linear motion for virtually every load rating… superior linear motion with friction-optimized, smooth and highly accurate performance.” nsk.com

Low Friction and High Speed

Rolling contact gives much lower friction compared to sliding contact. This allows higher speeds, smoother motion, less energy consumption and less heat generation. For example, the LM Guide documentation mentions “light movement with no clearance” and “infinite linear motion is possible.” thk.com

Load Capacity (Including Moments)

Because the carriage and rail are profiled and bolted together, linear guides can handle high radial loads, axial loads, and importantly, moment loads (tilt, yaw, roll). This capability is significantly greater than simple round shaft linear bearings, which struggle with moment loads. MISUMI highlights this in its selection of standard linear guides: “higher radial and moment loads” than round shaft linear ball bearings. us.misumi-ec.com

Long Travel and Modularity

Many linear guides allow “infinite” (or effectively unlimited) travel because the rail can be manufactured (or jointed) to long lengths and the rolling elements recirculate. For example, some manufacturers offer rails up to 6 m long or more. PBC Linear

Compactness and Rigidity

Because the rail is fixed and the guide is small, you can design compact motion systems that avoid bulky carriage arrangements, while achieving high rigidity. This is important when machine size, weight or footprint matter.

Maintenance and Clean Environments (when well sealed)

Modern linear guides can be designed with built-in lubrication systems, sealed carriages, corrosion-resistant materials, self-lubrication. This means less maintenance and suitability for harsh or clean environments (e.g., semiconductor, medical equipment). For example, igus’ drylin® line stresses that no grease or oil is required, making them suitable for dirty or hygiene-sensitive use. igus.com

Common Types of Linear Guides and Rails

There are several types of linear guide systems. Each has its design features, advantages, and trade-offs. Understanding the types helps you select the right one for your application.

Here are some of the major types:

Ball-Recirculating Linear Guides

This is perhaps the most common type: blocks with recirculating balls riding on hardened rails. Example: THK LM Guide. Benefits: good speed, decent loads, smooth. Trade-offs: may have slightly less stiffness than rollers or some specialty types. thk.com+1

Roller-Type Linear Guides

Instead of balls, roller bearings (cylindrical rollers, needles, tapered rollers) are used. These provide higher load capacity (especially for moment loads), better stiffness, but may cost more or have slightly higher friction. For example, Rollon mentions “tapered roller bearings” in their Heavy Line GU guides. rollon.com

Profiled Rail vs Round Shaft Guides

Some linear motion systems use round shafts and linear bushings (sliding or rolling) rather than a rail+block. The profiled rail + block arrangement is more rigid, handles moments better, and offers higher accuracy. MISUMI highlights this in its explanation of standard linear guides versus round shaft bearings. us.misumi-ec.com

Self-Aligning Linear Guides

In real machines, perfect alignment is rarely achieved. Self-aligning guides can accommodate slight misalignment between rail and block or base mounting. For example, Rollon’s Compact Rail & Compact Rail Plus mention self-alignment features. rollon.com

Corrosion-Resistant / Clean / Self-Lubricating Types

For environments where contamination, cleanliness, hygiene or corrosion are issues (e.g., food processing, medical, outdoor equipment), special linear guides are used. Example: igus’ self-lubricating series, or stainless-steel raceways in the Redi-Rail series. igus.com+1

Long Rail / Modular Systems

Some systems allow very long rails (several meters) or segments joined together for large travel. Example: Redi-Rail noting continuous lengths up to 6,000 mm. PBC Linear

How to Select Linear Guides and Rails: Key Criteria

Choosing the right linear guide system requires understanding system requirements and matching them to guide characteristics. Here are the main criteria to evaluate.

Load Requirements (Radial, Axial, Moment)

Radial load: The vertical load (perpendicular to rail).

Axial load: The load along the direction of travel.

Moment loads: The tilting or torque-type loads (pitch, yaw, roll) arising from overhangs, offset loads, carriage length etc.

You must ensure the chosen guide can handle all three (often worst-case) loads with a good safety factor.

Accuracy, Repeatability and Rigidity

Rigidity: The deflection under load; stiffer guides give better positional accuracy.

Repeatability and accuracy: How well the carriage returns to a reference point or holds positioning.

Clearance / Preload: Many guides are available in preloaded variants (removing clearance) to improve rigidity and accuracy.

Travel Length / Configuration

How far does the carriage need to go? If very long travel, choose a guide type that supports long rails or modular segments. Also consider cumulative errors, rail straightness over long lengths, mounting base stability.

Some applications need multi-rail, multi-carriage arrangements.

Speed & Dynamics

For high speed or high acceleration systems: friction, inertia, lubrication, heat generation matter. Choose a guide design suitable for high speed (ball recirculating if appropriate) and ensure adequate mounting, alignment and lubrication.

Environment / Operating Conditions

Contamination: Dust, chips, coolant may require sealed carriages, wipers, or self-lubricating types.

Corrosion: Outdoor, marine, food processing may need stainless steel, corrosion proof coatings.

Temperature: High/low temperature may affect materials, lubrication, thermal expansion.

Example: igus’ self-lubricating guide for dirty environments. igus.com

Mounting and Space Constraints

How much base area is available, what mounting orientation (vertical, horizontal, inverted)?

Space for rail, block, mounting bolts, service access.

Consider whether the rail is top mounted, side mounted, or base mounted.

Maintenance and Life-Cycle Costs

Lubrication frequency, ease of service, replacement intervals. Some guides offer built-in lubrication units or even no lubrication (self-lubricating). MISUMI notes lubrication every 50 km or six months (whichever comes first) for standard linear guides unless using an automated lubrication unit. us.misumi-ec.com

Long term cost includes downtime, replacement, and precision loss over time.

Cost vs Performance Trade-off

Higher accuracy, higher load capacity, special environment features usually drive cost up. You must balance performance requirements against budget.

Don’t over-spec beyond what you need—this wastes money and may add unnecessary complexity.

Vendor Support and Standards

Choose well-known brands, ensure spare parts availability, clear specifications, and support.

Many manufacturers publish detailed catalogs, selection tools, CAD models (see Rollon, THK, NSK etc). rollon.com+1

Summary Table: Selection Criteria

| Criterion | Key Questions |

|---|---|

| Load (radial/axial/moments) | What static/dynamic loads will the guide experience? |

| Accuracy & rigidity | What repeatability and deflection are acceptable? |

| Travel length & configuration | How far must the carriage travel? Multi-segment? |

| Speed & dynamics | What speeds/accelerations are required? |

| Environment | What contamination, temperature, corrosion issues? |

| Mounting/space | What space and orientation constraints exist? |

| Maintenance / life-cycle | What service intervals, lubrication needs? |

| Cost vs performance | What budget vs required spec? |

| Vendor & support | Is manufacturer reliable? Are spares available? |

By working through these questions and criteria, you’ll be far better placed to select a linear guide and rail system that suits your application rather than over- or under-specifying.

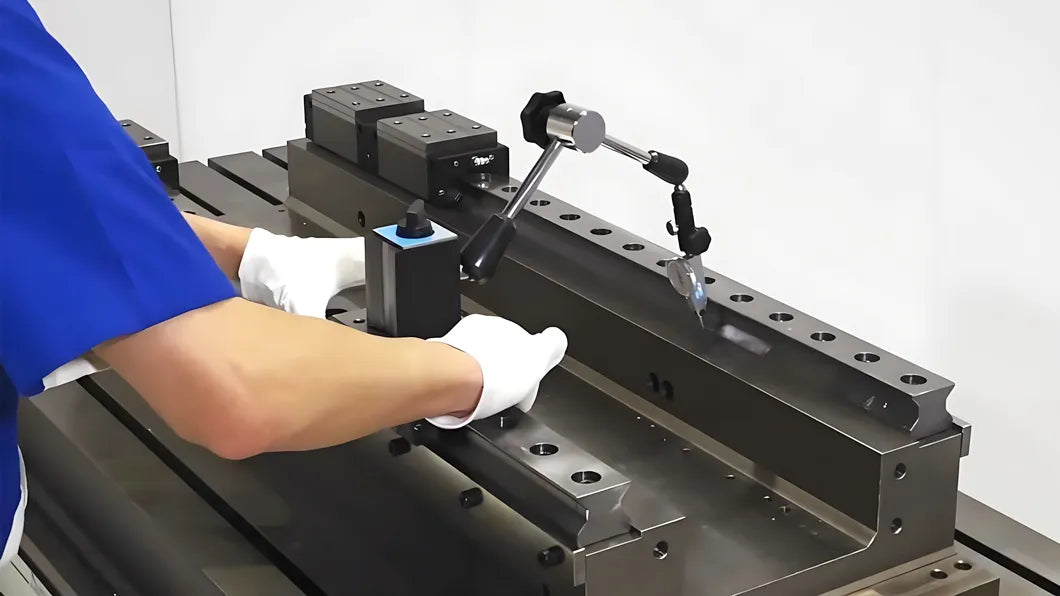

How to Install Linear Guides and Rails (Best Practices & Tips)

Even the best linear guide will fail to perform if not installed properly. Let’s go through some real-world practices and tips—drawn from experience and manufacturers’ guidance.

Base Preparation and Flatness

Ensure the base or machine bed where the rail will be mounted is flat within the specified tolerance (often micrometers over the rail length).

Remove surface burrs, debris, rust; ensure the surface is clean and free from chips or coolant residue.

If needed, apply surface preparation (grinding, lapping) to guarantee flatness and parallelism.

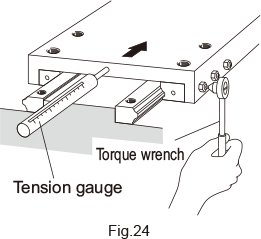

Rail Mounting and Alignment

Bolt the rail down loosely initially, then progressively tighten the bolts in a sequence (manufacturer typically provides a torque sequence).

If rails are long, ensure thermal expansion is taken into account (either via floating bolt or designated end bolts).

Use alignment tools (straight edges, dial gauges) to confirm rail straightness, twist, and parallelism if multiple rails or blocks are used.

Some systems require shims under the rail if the base is uneven.

Block or Carriage Mounting

After the rail is mounted, slide the block over the rail manually and check for smooth movement—not too tight, not too loose, no binding.

Preload: if the block/rail system allows preload adjustment (to remove clearance and increase rigidity), set this according to the manufacturer’s spec. For example, some roller carriage systems (Redi-Rail) allow side adjustment for preload. PBC Linear

Lubrication and Seals

Ensure that lubrication points are provided and initial lubrication is done before first move.

If the guide is sealed and prelubricated (or self-lubricating), ensure one does not override by applying incompatible lubricant.

For dirty environments (chips, dust, coolant) ensure wipers/seals are properly installed and not damaged.

Testing and Break-in

After installation, run the carriage through full travel several times under no-load, then under light load, gradually increase to full load.

Check for smoothness, any abnormal noise, increase in friction, binding or drift.

Record the baseline measurements for accuracy and repeatability so that future maintenance can be compared against this baseline.

Maintenance Access and Replacement

Ensure that bolts, lubrication ports, alignment features are accessible. Poor access often leads to neglected maintenance and eventual performance issues.

Consider how blocks or rails will be replaced or realigned if wear occurs; modularity helps.

Real-World Tip

In my own machine-tool retrofit projects, I found that one of the greatest causes of guide block wear or performance loss is micro-chips embedded beneath the rail (especially with coolant present). So I always install protective covers, wipers and ensure daily flushes of the mounting surfaces. This small step prevented scrap rates from creeping up.

Maintenance, Troubleshooting & Life-Cycle Considerations

Even though linear guides and rails are reliable, they still require thoughtful maintenance and monitoring. Neglect can lead to reduced accuracy, increased wear or failure. Here’s what you need to know.

Lubrication and Cleaning

Regular lubrication ensures rolling elements operate smoothly and avoid corrosion or galling. For instance, MISUMI recommends lubrication every 50 km or six months (whichever first) unless a built-in lubrication unit is used. us.misumi-ec.com

Clean the rail surface and carriage exterior regularly to remove chips, dust, coolant residue or contaminants.

Use correct lubricant type (grease, oil) as specified by the manufacturer; using wrong lubricant can reduce life.

Monitoring Wear and Performance

Periodically measure the smoothness of travel, friction forces, repeatability and any unusual noise or vibration.

Watch for changes in the preload setting, increase in block drag, or movement of the carriage due to wear.

Inspect seals and wipers for damage. In harsh environments, these can be the first failure point.

Alignment and Realignment

Over time, base plate settling, thermal cycling, machine vibration may alter alignment. Check rail and block alignment periodically.

If significant misalignment is detected, realign rails or replace shims, re-torque bolts as required.

Predicting Service Life

Manufacturers often provide dynamic load ratings and life calculations (e.g., L10 life in hours or kilometers). Use these to estimate replacement intervals.

Life is reduced by factors like: high speed, high load, frequent reversal, contamination, misalignment, poor lubrication.

Troubleshooting Common Problems

Here are some frequent problems and what to check:

| Issue | Possible Cause | Solution |

|---|---|---|

| Binding or jerky motion | Rail misalignment, debris under rail, block damage | Clean, realign, inspect block/rail |

| Excessive noise or vibration | Worn rolling elements, broken seal, insufficient preload | Replace block, check preload, replace seal |

| Loss of accuracy / drift | Base plate settlement, rail deflection, thermal shift | Re-measure, retorque, adjust base |

| Shortened life / early wear | Contamination, inadequate lubrication, incorrect preload | Improve environment protection, schedule lubrication, adjust preload |

| Over-heating, high friction | Wrong lubricant, mis-spec load/speed, incorrect block size | Confirm specifications, re-lubricate, choose correct system |

Examples from Practice

In one case I worked on a precision cutting machine: the linear guides were installed on a bed that gradually warped due to coolant and thermal cycling. Over six months the accuracy drifted by ~0.1 mm. After realigning and bolting down new rails, the precision returned. The key lesson: even the best guides cannot overcome base instability.

Applications of Linear Guides and Rails

Because of their versatility, linear guides and rails are used in many fields. Here are notable applications and reasons why they fit.

Machine Tools & CNC Machining

Precision machine tools require accurate, rigid motion guides. Linear guides ensure tool carriages move with minimal deflection, repeatably, and at high speed. For example, THK notes that linear guides contribute to machining accuracy by guiding the machine tool’s moving parts. thk.com

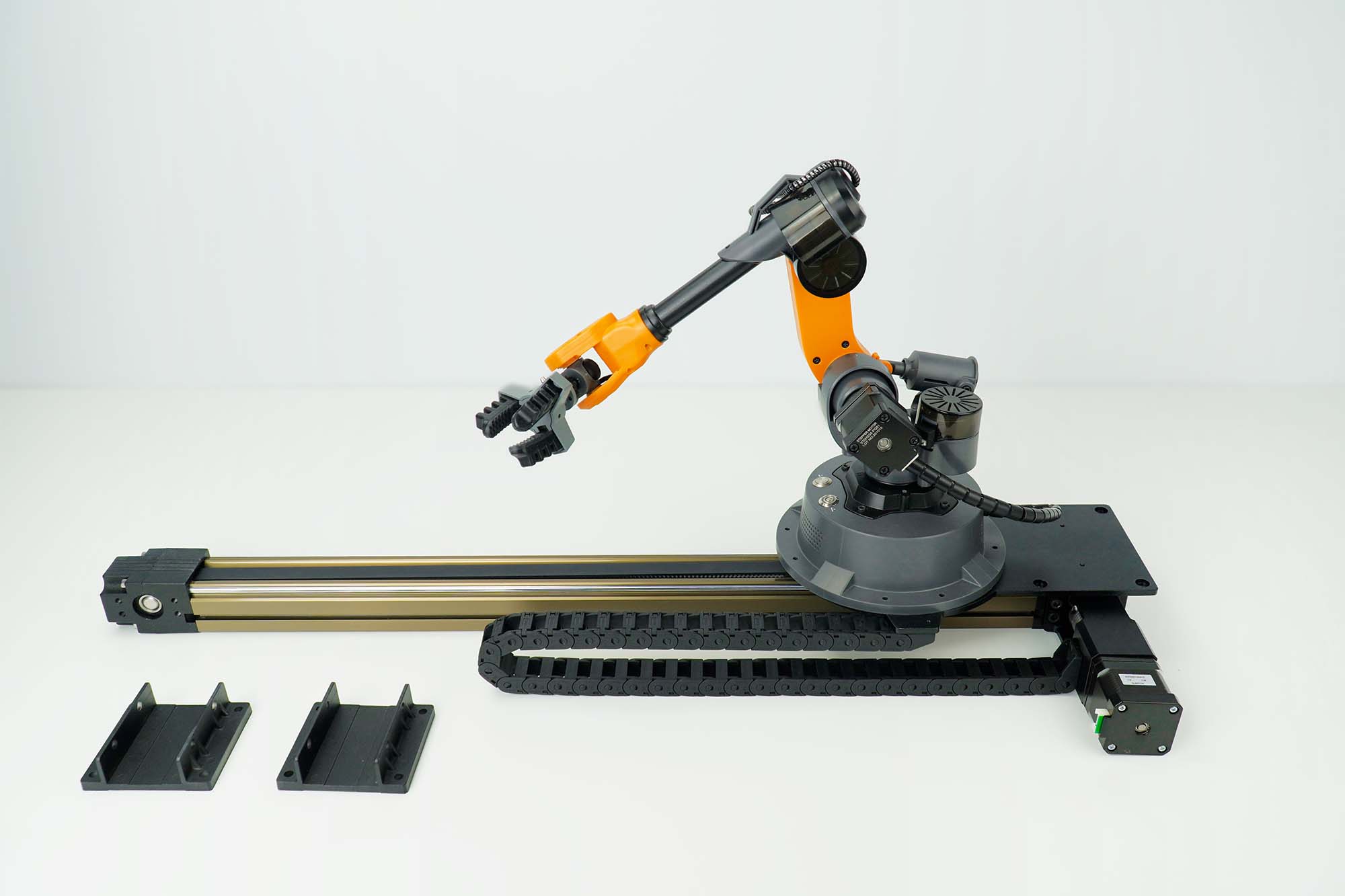

Robotics & Automation

In robotics, linear guides are used for sliders, pick-and-place axes, gantries, inspection systems. They provide smooth, accurate motion under varying loads. Manufacturers like Nadella highlight robotics and packaging as key fields. Nadella

Semiconductor Manufacturing

Semiconductor processing demands ultra-precision motion (sub-micron), clean environments, high speed. Linear guides with sealed blocks, low friction and precision raceways are critical.

Packaging & Assembly Lines

In packaging lines, speed and reliability matter. Linear guides with self-alignment features, long travel, and low maintenance are well suited (e.g., Rollon’s Compact Rail series for medium loads and compact design) rollon.com

Medical Equipment & Imaging

Equipment such as MRI tables, surgical robots, diagnostic devices need smooth, quiet, reliable motion under strict cleanliness standards. The low-friction and high-precision nature of linear guides help meet those needs. NSK mentions medical equipment as application. nsk.com

Other Specialized Uses

Aerospace / defense: positioning systems, guided devices. nsk.com

Clean rooms / food machines: self-lubricating rails (e.g., igus drylin®). igus.com

Material handling: long travel gantries, heavy loads.

Architecture/seismic isolation systems: some large scale linear guide systems are used for movement control in buildings (not just industrial machines).

The variety of applications shows just how fundamental linear guides and rails are to modern motion-systems design.

Challenges and Pitfalls (What to Watch Out For)

Even though linear guides and rails are excellent, they are not without challenges. Knowing what to watch out for can save time, cost and headaches.

Misalignment and Base Deflection

As mentioned before, the performance of a linear guide depends strongly on how straight and rigid the base is. A rail mounted on a warped or flexible base will deflect under load, which can cause binding, increased friction, wear, loss of accuracy and reduced life. This is a very frequent but often overlooked issue.

Contamination (Chips, Dust, Coolant)

In machining or factory environments, chips, coolant, dust can get between the carriage and raceways. This contaminant causes accelerated wear, increased friction and possibly failure. Choosing sealed or self-lubricating versions helps, but you must still maintain the environment.

Insufficient Lubrication or Wrong Lubricant

Neglecting lubrication or using incompatible grease can dramatically shorten the lifespan. Even sealed units may require periodic checks. Some users assume “sealed = no maintenance” which can be false in harsh environments.

Over-specing or Under-specing

Under-specing: Choosing a guide with insufficient load or rigidity will lead to poor performance, excessive wear, or failure.

Over-specing: Picking the highest specification when not needed can be wasted cost and heavier than necessary. Always match requirements to the system.

Thermal Expansion / Length Effects

For long rails, thermal expansion, straightness deviations, mounting expansion must be managed. Also longer rails may accumulate error along the length (straightness, wear). Segmenting, using floating mounts or expansion joints may help.

Preload Mis-setting

Preload is often adjusted to eliminate clearance and improve rigidity. But if set too tight, friction rises, wear increases, temperature may increase; too loose and you get play. The correct preload must be set according to manufacturer spec. For example, Redi-Rail allows side-adjustable preload. PBC Linear

Maintenance Access Neglected

If the design makes it hard to access lubrication ports, inspect and replace blocks, the maintenance will suffer and the system will degrade faster.

End-of-Life and Replacement Strategy

Even high quality linear guides wear slowly, especially with repeated travel reversals, heavy loads, misalignment etc. Plan for inspection, life-prediction, maybe replacement or re-grinding rails before accuracy falls too far.

Cost-Benefit and Life-Cycle Considerations

When budgeting for linear guides and rails, it’s not just the purchase cost but the total life-cycle cost that matters. Let’s break down what that means.

Initial Cost

This includes: rail + carriage/block + mounting hardware + installation labor + alignment time + shields/covers if needed. Higher performance (higher load, higher precision, corrosion resistant) means higher cost.

Installation Cost

Mounting requires precision base, alignment tools, may require base preparation. Labor cost can be significant.

Operational Cost

Lower friction translates to lower energy consumption. Lower friction and precise motion may reduce cycle time or improve throughput. Lower maintenance needs reduce downtime. Higher accuracy may reduce scrap and rework (saving money).

Maintenance Cost

Lubrication, cleaning, inspection, possible replacement of blocks or rails. If neglected, this cost can escalate (unexpected downtime, higher scrap rate, more wear, early failure).

Life / Replacement Cost

Estimating useful life based on load/speed/environment is important. Replacing worn guides prematurely is costly; but waiting too long can cause damage to machine or produce poor output.

ROI (Return on Investment)

The case for linear guides becomes clear when:

You need high precision or repeatability.

You need low friction, high speed.

You need high rigidity or moment load capacity.

You face tough environment or long travel.

In such cases the increased cost is justified by lower scrap, higher throughput, lower downtime and better quality.

In one machine I worked on, moving from simple round-shaft linear bushings to a profiled rail + block system cost ~20% more upfront, but reduced positional error by ~0.15 mm, allowed speed increase by ~30%, and lowered maintenance downtime by ~40% over a year. The pay-back occurred within about 8 months.

Future Trends in Linear Guides and Rails

Like all mechanical components, linear guides and rails continue to evolve. What are some of the trends to watch?

Longer Travel, Modular Systems

As automation and large-format machines (gantries, additive manufacturing, large-area scanning) increase, there is demand for longer rails, modular segments, easier installation over long distances while maintaining accuracy. For example, some rails now deliver lengths of 6 m or more. PBC Linear

Integration with Sensors and IoT

Smart linear guides will likely integrate sensors (for preload, wear, temperature, vibration) enabling predictive maintenance and reduced downtime. Monitoring guide block health and rail alignment in real time will become more common.

Improved Materials and Coatings

Developments in materials (stainless steel, ceramic bearings, hybrid coatings) to reduce wear, corrosion, lighter weight, higher temperature capability. For example, manufacturer marketing highlights special coatings and lubricants for specific environments. nsk.com

Self-Lubricating and Maintenance-Free Designs

Guides like igus’ drylin® already offer self-lubricating systems that are ideal for dirty/clean/hygiene environments. Expect further expansion in maintenance-free linear motion systems. igus.com

Environmental and Energy Efficiency

Lower friction systems means lower energy consumption. Also better precision means less waste and scrap—so there is an environmental benefit. In machine tool and robotics markets, efficiency is becoming a selling point.

More Customization and Smart Selection Tools

Online configurators, CAD download, simulation tools help designers choose proper guide systems more easily. For example, Rollon offers selection tools for different types of linear guides. rollon.com

Real-World Example: Specifying a Linear Guide System

Let’s walk through a simplified example of selecting a linear guide for a pick-and-place automation axis.

Step 1: Define the requirements

Travel length: 1200 mm

Load: carriage plus payload = 50 kg

Speed: up to 1 m/s, acceleration 5 m/s²

Orientation: horizontal axis with occasional vertical component

Environment: factory with occasional dust/chips, moderate coolant exposure

Accuracy: ±0.02 mm repeatability

Life expectancy: 5 years with daily usage (2 shifts)

Step 2: Calculate or estimate loads

Radial load (perpendicular): 50 kg × 9.81 ≈ 490 N

Axial load: assume moderate, say 100 N due to inertial forces

Moment loads: consider overhangs, cantilever length, braking loads — estimate moment about rail axis = 50 kg × 0.3 m = 15 kg·m ~ 147 N·m (approx)

Step 3: Select guide type

Because travel is long (1200 mm), we need a rail capable of that length, mounting on base.

Because environment has some chips/coolant, choose sealed carriage or self-lubricating variant.

Because precision is ±0.02 mm, pick a preload version to eliminate clearance.

Because repeatability and moment load matter, choose a double rail/dual-block arrangement for better moment handling.

Choose ball recirculating type if speed is top priority, or roller type if moment demands high. Here moderate moment so ball type suffices.

Step 4: Vendor/Model Consideration

Visit catalogues of manufacturers like THK, NSK, Rollon. Confirm dynamic load rating > designed load (with safety factor 2~3). Confirm rail length availability, mounting flatness requirement, preload options, seals etc.

Step 5: Installation Plan

Prepare machine bed for flatness within required spec (e.g., ±0.02 mm over 1200 mm). Mount rails carefully, torque bolts, align blocks, set preload, test travel with load, measure repeatability and friction.

Step 6: Maintenance Plan

Schedule lubrication every 6 months (or according to manufacturer). Inspect seals annually. Record baseline performance, monitor for increased friction/noise.

By following a structured approach like this you avoid under- or over-specifying, ensure the guide system will perform as required, and align installation and maintenance accordingly.

THK SHS20‑220L Linear Guide Rail: A branded high-precision linear guide rail from THK, good for serious machine tool/industrial use, with hardened rail, matching blocks, etc.

12mm SBR12 Linear Bearing Rail Slide Kit: A smaller size rail/slide kit, suitable for light loads, prototyping, hobby use.

12mm 55 Rail Guideway System Linear Motion: Similar small guideway system, focusing on linear motion for perhaps optical or lighter duty systems.

VEVOR SFC20‑1200mm Linear Rail Slide Guide: Longer travel rail slide (1200mm) for DIY CNC, gantry, or other motion systems.

200mm Stroke CNC Linear Stage Motion Actuator: A motion stage including guide rail, usually pre-integrated, useful for integrated assembly or lab equipment.

Makita Guide Rails 1400mm ONE Size: More general guide rails used perhaps for woodworking power tools, reflecting that linear rail concept applies beyond industrial machinery.

(And alternates show the variety of price/performance tiers.)

When choosing among these you still must check: load rating, moment rating, accuracy class, environmental suitability, length, mounting interface, compatibility with carriage blocks, availability of service/spares.

FAQ (Frequently Asked Questions)

What is the difference between a linear guide and a linear rail?

A “linear rail” typically refers to the fixed track (the rail) element, while “linear guide” often refers to the system including the rail + carriage/block + rolling elements. In practice many people use both terms interchangeably (i.e., “linear guide/rail system”). The key is to recognize that the system comprises both the rail and the moving block.

Can I use a round-shaft bearing slide instead of a profiled rail?

Yes, in simpler, lower-load, lower-accuracy applications you might use a round shaft with linear bushings or bearings. However, profiled rail + block systems provide higher load capacity, better moment load handling, higher accuracy and better rigidity. MISUMI explains that standard linear guides (rail + block) offer significantly more radial and moment load capacity than round shaft linear bearings. us.misumi-ec.com

How long can a linear guide rail be?

It depends on the manufacturer and system. Some systems allow rails of several meters in length (for example up to 6,000 mm in certain series) or modular segments joined together. PBC Linear However, you must also consider mounting base flatness, straightness of the rail, cumulative alignment errors and expansion effects.

Do I need to preload a linear guide?

Preloading removes clearance between the carriage and rail raceways and improves rigidity and accuracy. If your application demands high repeatability, no play, good moment handling, then yes – a preloaded block is beneficial. But preload also increases friction and may reduce lifespan if excessive. So you must follow manufacturer guidelines and match to your performance vs cost trade-off.

What is the maintenance requirement for linear guides and rails?

Maintenance depends on duty, environment and design. Generally: periodic lubrication (every so many meters of travel or time interval), cleaning of rails and carriages, inspection for wear/seals, checking alignment. Some self-lubricating or sealed units reduce maintenance significantly (for example igus’ drylin® series). igus.com

How do I choose between ball-type and roller-type linear guides?

Ball-type: good speed, moderate loads, good general purpose.

Roller‐type: higher load capacity, higher moment loads, better stiffness, but may cost more/introduce more friction.

Consider load, stiffness, accuracy, cost, speed and environment. If loads and moments are high, roller type might be better; if speed and moderate loads dominate, a ball type may suffice.

Conclusion

In summary, linear guides and rails are fundamental components in modern precision motion systems. They bring together hardened rails, rolling elements, sealed carriages, and mounting systems to deliver smooth, accurate, repeatable linear motion under demanding conditions. From their historical origin as simple ball bushings to today’s high-performance profiled rails, their evolution reflects the increasing demands for precision, speed, reliability and longevity.

When you select, install and maintain them properly—taking into account loads, alignment, environment, lubrication and baseline performance—you unlock major advantages: higher throughput, lower scrap, better accuracy, less downtime. On the flip side, neglecting installation or maintenance, mis-specifying the system, or ignoring the base structure will compromise performance quickly.

As machines become smarter, larger, distributed and more demanding, the role of these linear motion systems will only grow. With embedded sensors, longer modules, maintenance-free materials and more modular systems, the future is bright for linear guides and rails. So whatever your next machine design or automation project, give due weight to this seemingly “simple” component—it may well drive your performance.

Suggestions for Inbound and Outbound Links

Inbound (internal links you could add on your site):

Link to your article on “Precision motion systems in CNC machines”

Link to your article on “How to maintain machine tool guideways and bearings”

Link to your article on “Selecting linear motion components for automation”

Outbound links (to credible external resources):

THK Linear Guides – design & selection overview. thk.com

Rollon linear guides – product families and selection. rollon.com

igus drylin® self-lubricating linear guides. igus.com