Outline for “Linear Guides”

| Heading | Sub-Headings |

|---|---|

| Introduction to Linear Guides | Role in modern engineering |

| What are Linear Guides? | Definition and core function |

| History of Linear Guides | From sliding mechanisms to precision rails |

| Types of Linear Guides | Ball, roller, plain, magnetic |

| How Linear Guides Work | Friction reduction and load distribution |

| Key Components of Linear Guides | Rails, blocks, rolling elements |

| Advantages of Linear Guides | Speed, rigidity, and durability |

| Limitations of Linear Guides | Cost, maintenance, contamination |

| Applications of Linear Guides | CNC, robotics, 3D printing, healthcare |

| Linear Guides in CNC Machines | Precision under cutting forces |

| Role in Robotics and Automation | Accuracy in repetitive motion |

| Use in 3D Printing | Ensuring smooth and accurate movement |

| Medical and Laboratory Applications | Imaging, diagnostic, and surgical tools |

| Linear Guides in Aerospace and Automotive | High precision in production |

| Factors to Consider When Choosing Linear Guides | Load, speed, and environment |

| Materials Used in Linear Guides | Steel, ceramic, polymers |

| Load Capacity of Linear Guides | Static and dynamic load ratings |

| Installation of Linear Guides | Alignment and setup best practices |

| Lubrication of Linear Guides | Grease, oil, and auto-lubrication |

| Maintenance Practices | Cleaning, inspection, and replacement |

| Common Issues with Linear Guides | Misalignment, wear, contamination |

| How to Extend the Life of Linear Guides | Proper use and protection |

| Linear Guides vs. Other Linear Motion Systems | Ball screws, plain slides |

| Future of Linear Guides | Smart sensors and IoT integration |

| Cost vs. Performance Analysis | Balancing investment and benefits |

| Linear Guides | Their overall importance |

| Frequently Asked Questions about Linear Guides | Six FAQs |

| Conclusion | Final thoughts |

Introduction to Linear Guides

Precision engineering would not be possible without linear guides. These unsung heroes are at the heart of countless machines, ensuring movement is accurate, smooth, and reliable. From CNC machining centers to robotic arms and 3D printers, linear guides make sure components move exactly where they need to be—without deviation.

Their role may appear small, but their impact is monumental. They define performance, enhance reliability, and reduce wear in industries where tolerances are measured in microns.

What are Linear Guides?

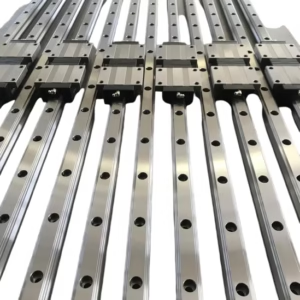

Linear guides are mechanical components that facilitate smooth, precise, and low-friction linear motion along a fixed path. Unlike rotary bearings that support rotational movement, linear guides ensure back-and-forth travel along rails or tracks.

Each linear guide system typically consists of a hardened steel rail and a sliding block (or carriage) equipped with rolling elements like balls or rollers. This setup guarantees accuracy, repeatability, and rigidity in demanding environments.

History of Linear Guides

Before linear guides, engineers relied on plain sliding surfaces, where friction was reduced with lubricants. While functional, these systems wore out quickly.

The industrial revolution brought hardened rails and rolling-element bearings, drastically improving durability and accuracy. Modern linear guides now use advanced coatings, precision grinding, and even self-lubricating materials, making them more efficient and long-lasting than ever before.

Types of Linear Guides

Different applications call for different linear guide designs:

Ball Linear Guides – Use circulating steel balls for smooth, low-friction motion. Perfect for high-speed, medium-load applications.

Roller Linear Guides – Employ cylindrical rollers for greater rigidity and load capacity. Best suited for heavy-duty operations.

Plain Linear Guides – Utilize low-friction sliding materials like polymer composites. Ideal for environments with dust or chemicals.

Magnetic Linear Guides – Use magnetic levitation for near-frictionless movement, though expensive and less common.

How Linear Guides Work

Linear guides work by minimizing friction between a rail and a carriage. In ball or roller designs, rolling elements circulate inside the block as it moves, reducing resistance and distributing load evenly. In plain designs, a low-friction surface slides along the rail.

This mechanism ensures smooth, precise, and repeatable linear movement, even under heavy loads or high speeds.

Key Components of Linear Guides

Guide Rail – Provides the path of travel.

Carriage/Block – The moving component carrying loads.

Rolling Elements – Balls or rollers reducing friction.

Seals and End Caps – Protect against dirt and retain lubrication.

Lubrication System – Maintains smooth operation.

Advantages of Linear Guides

High precision and repeatability

Smooth, low-friction movement

Long service life

High load-carrying capacity

Rigidity under stress

These qualities make linear guides indispensable for modern industries.

Limitations of Linear Guides

Cost – More expensive than plain guides.

Maintenance – Require lubrication and inspection.

Contamination – Susceptible to dust and debris.

Installation Complexity – Misalignment can reduce lifespan.

Applications of Linear Guides

Linear guides are found in a wide variety of industries:

CNC machining and milling

Robotics and industrial automation

3D printing

Aerospace and automotive manufacturing

Medical and laboratory equipment

Packaging and conveyor systems

Linear Guides in CNC Machines

CNC machining demands accuracy under heavy loads. Linear guides provide rigidity, reducing vibration and maintaining tool precision. This ensures better surface finishes, higher productivity, and longer tool life.

Role in Robotics and Automation

Robots need precise, repeatable movement. Linear guides ensure that robotic arms, pick-and-place systems, and assembly-line equipment can perform tasks reliably at high speed.

Use in 3D Printing

In additive manufacturing, precision is crucial. Linear guides keep the print head and bed stable, ensuring clean layers and consistent prints, reducing the risk of print failures.

Medical and Laboratory Applications

Linear guides enable precise motion in diagnostic equipment, MRI scanners, and surgical robots. Their smooth, quiet operation makes them ideal for sensitive environments.

Linear Guides in Aerospace and Automotive

In aerospace and automotive industries, where accuracy and reliability are paramount, linear guides ensure machining tolerances are met while handling large, heavy components.

Factors to Consider When Choosing Linear Guides

Load requirements

Speed of travel

Precision needs

Environmental conditions

Maintenance requirements

Budget constraints

Materials Used in Linear Guides

Hardened Steel – Strong and wear-resistant.

Stainless Steel – Corrosion-resistant.

Ceramic Coatings – Reduce friction and extend lifespan.

Polymer Inserts – Quiet and low-maintenance.

Load Capacity of Linear Guides

Linear guides are rated for both static and dynamic loads. Roller guides handle heavier loads, while ball guides are optimized for lighter, faster operations.

Installation of Linear Guides

Proper installation ensures longevity:

Rails must be mounted on flat surfaces.

Bolts must be tightened with correct torque.

Lubrication should be applied before use.

Alignment must be precise to avoid premature wear.

Lubrication of Linear Guides

Grease – Provides long-lasting lubrication.

Oil – Suitable for high-speed movement.

Automatic Lubrication – Common in large industrial machines.

Maintenance Practices

Regular cleaning of rails

Monitoring lubrication levels

Checking seals for damage

Replacing worn components

Common Issues with Linear Guides

Misalignment causing uneven wear

Contamination leading to damage

Insufficient lubrication

Excessive loads reducing service life

How to Extend the Life of Linear Guides

Install protective covers

Follow load and speed ratings

Lubricate at recommended intervals

Inspect regularly for wear or noise

Linear Guides vs. Other Linear Motion Systems

| System | Motion Type | Pros | Cons |

|---|---|---|---|

| Linear Guides | Rail and block | Precision, rigidity | Higher cost |

| Ball Screws | Screw-driven | High accuracy | Slower |

| Plain Slides | Sliding surfaces | Low cost, durable | Higher friction |

Future of Linear Guides

The future lies in smart, sensor-enabled linear guides that monitor wear, load, and temperature in real-time. IoT integration will allow predictive maintenance, while eco-friendly lubricants and materials will improve sustainability.

Cost vs. Performance Analysis

Although costlier than alternatives, linear guides save money in the long run by:

Reducing downtime

Increasing efficiency

Extending machine lifespan

Improving product quality

Linear Guides

In essence, linear guides are more than components—they are enablers of precision, productivity, and reliability. Their role in shaping the future of manufacturing, healthcare, and automation is undeniable.

Frequently Asked Questions about Linear Guides

What are linear guides used for?

They provide smooth, precise motion in CNC machines, robots, printers, and medical equipment.

Are linear guides expensive?

Yes, but they offer long-term savings through durability and efficiency.

How often should linear guides be lubricated?

It depends on usage, but regular lubrication is essential to prevent wear.

What is the difference between ball and roller linear guides?

Ball guides are suited for speed and light loads, while roller guides handle heavy-duty applications.

Can linear guides operate in dirty environments?

Yes, but protective covers and seals are strongly recommended.

Do linear guides require alignment during installation?

Yes, precise alignment is crucial to ensure smooth motion and long service life.

Conclusion

Linear guides are at the core of precision engineering. Their ability to provide stable, smooth, and accurate movement makes them essential in industries where even the smallest error can have major consequences.

As technology advances, linear guides will evolve into smarter, more sustainable, and even more efficient systems, continuing to shape the future of automation and engineering.

Inbound Link Suggestions

Link to article on Linear Motion Bearings

Link to article on CNC Machine Technology

Link to article on Robotics in Industry