Linear guide rails, also known as linear motion guides, are crucial components in modern machinery and automation systems. They enable precise, smooth, and reliable linear motion for a wide range of industrial applications. Linear guide rails are widely used in CNC machines, 3D printers, robotic systems, medical equipment, and other precision-driven environments. By minimizing friction and distributing loads evenly, they improve the efficiency, accuracy, and lifespan of mechanical systems.

This comprehensive guide explores the fundamental aspects of linear guide rails, including their types, components, materials, benefits, applications, selection criteria, installation, maintenance, and troubleshooting. Whether you are an engineer, technician, or industry enthusiast, understanding linear guide rails can help optimize performance, reduce downtime, and enhance productivity.

Table of Contents

What Are Linear Guide Rails?

Components of Linear Guide Rail Systems

Types of Linear Guide Rails

Materials Used in Linear Guide Rails

Advantages of Linear Guide Rails

Applications of Linear Guide Rails

Factors to Consider When Selecting Linear Guide Rails

Installation and Alignment of Linear Guide Rails

Maintenance and Lubrication

Common Issues and Troubleshooting

Innovations and Future Trends in Linear Guide Rails

Frequently Asked Questions

Conclusion

1. What Are Linear Guide Rails?

Linear guide rails are mechanical components that provide stable and precise linear motion along a predetermined path. They consist of a rail and a carriage or slider that moves along it, typically incorporating rolling elements such as balls or rollers to reduce friction. These systems are designed to handle different load types—including radial, axial, and moment loads—while maintaining high accuracy and repeatability.

Linear guide rails differ from traditional sliding mechanisms in that they offer minimal resistance, uniform motion, and longer operational life. They are especially valuable in applications requiring high-speed, high-precision linear motion.

2. Components of Linear Guide Rail Systems

A standard linear guide rail system generally comprises the following components:

2.1. Rail

Description: The fixed track or pathway for the moving carriage.

Features: Precision-ground surfaces, hardened steel or stainless steel, groove patterns for rolling elements.

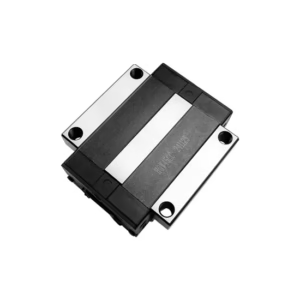

2.2. Carriage or Slider

Description: The moving component that travels along the rail.

Features: Contains recirculating balls or rollers, housing for load distribution, mounting holes for attachments.

2.3. Rolling Elements

Description: Balls or rollers that circulate within the carriage to reduce friction.

Function: Enables smooth, precise motion and minimizes wear on both the rail and carriage.

2.4. End Caps and Seals

End Caps: Prevent rolling elements from falling out.

Seals: Protect against dust, dirt, and contaminants, extending the life of the guide rail system.

3. Types of Linear Guide Rails

Linear guide rails are categorized based on the type of rolling element, carriage design, and intended application.

3.1. Ball-Type Linear Guide Rails

Mechanism: Recirculating balls reduce friction between the carriage and rail.

Advantages: High precision, smooth motion, suitable for light to medium loads.

Applications: CNC machinery, 3D printing, precise robotic movements.

3.2. Roller-Type Linear Guide Rails

Mechanism: Cylindrical or needle rollers instead of balls provide motion.

Advantages: Higher load capacity than ball types, better for heavy-duty applications.

Applications: Industrial automation, machine tools, large-scale manufacturing.

3.3. Profile Rail vs. Round Rail

Profile Rail: Rectangular cross-section, high precision, ideal for heavy and moment loads.

Round Rail: Cylindrical design, lighter, simpler mounting, suitable for smaller applications.

3.4. Miniature Linear Guide Rails

Description: Compact systems for small-scale devices.

Applications: Medical instruments, laboratory automation, micro-assembly.

4. Materials Used in Linear Guide Rails

Material selection affects durability, friction, and environmental compatibility.

4.1. Carbon Steel

Strong, durable, cost-effective.

Often heat-treated for hardness.

4.2. Stainless Steel

Corrosion-resistant, suitable for outdoor or humid environments.

Used in medical, food, and chemical applications.

4.3. Aluminum

Lightweight, corrosion-resistant, and easy to machine.

Applied in aerospace and portable equipment.

4.4. Polymers and Composites

Low friction, noise reduction, chemical resistance.

Used in cleanroom applications or where lubrication is limited.

5. Advantages of Linear Guide Rails

Linear guide rails offer numerous benefits:

Precision and Accuracy: High repeatability, ideal for CNC and automated systems.

Low Friction: Reduced wear and energy consumption.

Load Handling: Capable of supporting axial, radial, and moment loads.

Durability: Long lifespan with proper maintenance.

Smooth Motion: Minimal vibration and noise.

Flexibility: Suitable for a wide range of industrial applications.

6. Applications of Linear Guide Rails

Linear guide rails are used extensively across industries:

6.1. CNC Machines

Guides cutting tools and tables with high accuracy.

6.2. 3D Printers

Provides precise movement of print heads and build plates.

6.3. Robotics

Ensures smooth linear motion in robotic arms and automated assembly.

6.4. Industrial Automation

Used in packaging, conveyor systems, and material handling equipment.

6.5. Medical Equipment

Supports precise positioning in imaging systems, lab automation, and surgical devices.

6.6. Aerospace and Defense

Used in high-precision instruments, satellite mechanisms, and control systems.

7. Factors to Consider When Selecting Linear Guide Rails

When choosing linear guide rails, consider:

Load Requirements: Both static and dynamic.

Precision: Tolerance, repeatability, and positional accuracy.

Speed: High-speed motion may require specific bearing types.

Environment: Temperature, humidity, chemical exposure, dust.

Space Constraints: Length, width, and mounting compatibility.

Maintenance Needs: Some systems are easier to maintain than others.

8. Installation and Alignment

Proper installation ensures optimal performance and longevity.

8.1. Surface Preparation

Ensure mounting surfaces are flat, clean, and rigid.

8.2. Alignment

Parallelism and straightness of rails are critical.

Misalignment leads to uneven wear, friction, and performance issues.

8.3. Fastening

Use correct torque specifications.

Avoid over-tightening, which can distort rails or carriages.

8.4. Testing

Check for smooth motion and correct load distribution before full operation.

9. Maintenance and Lubrication

Maintenance ensures long-term performance:

Cleaning: Remove dust, debris, and contaminants.

Lubrication: Use grease or oil compatible with rail materials.

Inspection: Check for wear, damage, and corrosion.

Replacement: Replace worn or damaged components promptly.

10. Common Issues and Troubleshooting

Linear guide rails may face:

Noise or Vibration: Often due to misalignment or insufficient lubrication.

Sticking or Jamming: Caused by dirt, debris, or damaged rolling elements.

Excessive Wear: Results from contamination or overloading.

Corrosion: Occurs in humid or chemically aggressive environments.

11. Innovations and Future Trends

Recent advancements in linear guide rail technology include:

High-Speed Rail Systems: For ultra-fast automation applications.

Lightweight, Compact Designs: Reduce weight without compromising load capacity.

Integrated Sensors: Monitor load, motion, and condition for predictive maintenance.

Advanced Materials and Coatings: Reduce friction, improve durability, and resist corrosion.

12. Frequently Asked Questions

Q1: Can linear guide rails handle heavy loads?

A1: Yes, roller-type and profiled rails can support high axial, radial, and moment loads.

Q2: How often should linear guide rails be lubricated?

A2: Depending on the application, load, and speed, weekly to monthly maintenance is recommended.

Q3: What is the difference between ball and roller linear guide rails?

A3: Ball rails offer high precision and smooth motion for light to medium loads; roller rails support heavier loads with slightly less precision.

Q4: Are linear guide rails suitable for outdoor use?

A4: Stainless steel or coated rails prevent corrosion in outdoor and humid environments.

13. Conclusion

Linear guide rails are essential in modern machinery, providing smooth, precise, and reliable linear motion. Correct selection, installation, and maintenance enhance performance and lifespan, making them indispensable for industrial automation, CNC machining, 3D printing, robotics, medical equipment, and aerospace applications. Continuous advancements in materials, sensors, and design ensure that linear guide rails remain a cornerstone of high-precision mechanical systems.

By understanding the types, materials, advantages, and applications of linear guide rails, engineers and technicians can optimize machine efficiency, reduce downtime, and improve overall system accuracy.