Introduction to Linear Rail Bearing

A linear rail bearing is one of the most critical innovations in motion systems. It enables smooth, accurate, and controlled linear motion across multiple industrial applications. Unlike rotary bearings, which support circular movement, linear rail bearings support straight-line travel. They are widely used in CNC machines, robotics, packaging, and even medical devices.

The concept of linear motion dates back centuries, where craftsmen used wooden slides and lubricants like animal fat to reduce friction. However, those primitive systems lacked the precision required for modern applications. With industrial advancement, the introduction of rolling elements inside carriages revolutionized the way machines handled linear movement.

Today, industries prefer linear rail bearings because they combine high precision, durability, and load-bearing capacity in compact systems. They are especially vital where repeatable accuracy is essential, such as in semiconductor manufacturing or robotic arms. Without them, modern automation would not function as efficiently as it does.

Linear Rail Bearing Explained

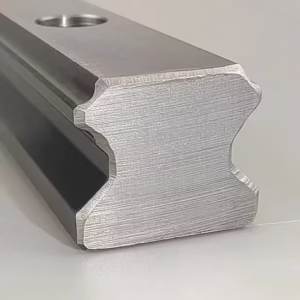

At its simplest, a linear rail bearing consists of two parts: the rail (or guide) and the carriage (or block). The rail is typically mounted on a fixed base, while the carriage moves along it, thanks to rolling elements like balls or rollers.

Structure and Design: Rails are precision-ground to ensure accuracy, while carriages hold rolling elements that distribute load evenly.

Materials Used: Stainless steel is common for corrosion resistance, hardened steel for heavy-duty applications, and aluminum alloys for lightweight needs.

Precision Engineering: Manufacturers maintain micron-level tolerances. Any misalignment, even at the smallest scale, could cause uneven wear and reduced performance.

These features allow linear rail bearings to deliver smooth, frictionless movement, which is why they are widely chosen for applications where accuracy is paramount.

Types of Linear Rail Bearing

There are multiple types of linear rail bearings, each suited for specific conditions:

Ball-Type Linear Bearings: The most common type, using recirculating steel balls to ensure smooth motion. They are cost-effective and precise.

Roller-Type Linear Bearings: Instead of balls, these use cylindrical rollers, offering higher load capacity and rigidity.

Plain Linear Bearings: These lack rolling elements and slide directly on the rail. While simpler, they are less efficient and better suited for lower loads.

Compact and Miniature Bearings: Designed for small devices, like medical equipment or 3D printers, where space is limited but precision is still crucial.

Each type comes with trade-offs in terms of load capacity, precision, and cost.

Working Principle of Linear Rail Bearing

The magic of linear rail bearings lies in how they reduce friction while ensuring stability.

Motion Transfer Mechanics: Rolling elements recirculate inside the carriage, continuously transferring loads from one end to the other.

Load Distribution: By spreading the load across multiple points, stress is minimized, enhancing service life.

Friction Reduction: Unlike sliding motion, rolling motion drastically reduces energy loss, allowing machines to operate faster and more efficiently.

This principle is why linear bearings are vital in automation, where both speed and accuracy must coexist.

Advantages of Linear Rail Bearing

The benefits of using linear rail bearings are numerous:

High Precision and Accuracy: Perfect for CNC and robotics.

Durability and Long Service Life: Hardened materials and specialized lubrication extend lifespan.

Reduced Friction and Smooth Operation: Less wear and tear compared to sliding bearings.

Cost-Effectiveness: While initial investment is higher, long-term savings on maintenance and efficiency make them economical.

Their ability to combine accuracy, longevity, and cost savings makes them invaluable across industries.

Applications of Linear Rail Bearing

Linear rail bearings have transformed how industries function.

CNC Machinery: Provides accuracy for cutting, milling, and engraving.

Robotics and Automation: Ensures repeatable precision in robotic arms.

Medical Equipment: Supports imaging devices and surgical robots.

Aerospace and Defense: Critical in simulators and precision assembly.

Packaging Industries: Enables fast and accurate packaging operations.

Essentially, any industry requiring precision linear motion depends on these components.

Linear Rail Bearing vs Other Bearings

Comparisons highlight why linear rail bearings are unique:

Linear vs Rotary Bearings: Rotary bearings support circular motion, while linear bearings enable straight-line travel.

Linear vs Plain Sliding Bearings: Sliding bearings have higher friction, while linear rail bearings glide smoothly.

Linear vs Magnetic Bearings: Magnetic systems offer near-frictionless motion but are more expensive and complex.

This makes linear rail bearings the most practical choice for most industries.

Design Considerations for Linear Rail Bearing

Choosing the right bearing involves multiple factors:

Load Capacity: The heavier the load, the stronger the bearing required.

Speed Requirements: High-speed applications need ball-type bearings with excellent lubrication.

Environmental Factors: Dust, moisture, or chemicals can affect lifespan.

Maintenance Needs: Systems requiring minimal upkeep may benefit from self-lubricating designs.

Engineers must balance these factors to achieve maximum performance.

Installation of Linear Rail Bearing

Proper installation is critical for efficiency.

Preparation: Clean surfaces and check alignment.

Tools Required: Torque wrenches, alignment tools, and lubricants.

Step-by-Step Guide:

Mount the rail securely.

Place the carriage carefully without damaging rolling elements.

Tighten bolts with correct torque.

Test motion for smoothness.

A misaligned bearing can shorten its lifespan drastically.

Maintenance of Linear Rail Bearing

Keeping a linear rail bearing in peak condition requires:

Lubrication Methods: Grease or oil lubrication reduces friction and wear.

Cleaning Techniques: Regular removal of dust and contaminants.

Common Wear Signs: Increased noise, vibration, or uneven movement.

Preventive Maintenance: Scheduled checks extend service life significantly.

Neglecting maintenance often leads to costly replacements.

Common Problems with Linear Rail Bearing

Some frequent issues include:

Misalignment: Causes uneven wear.

Excessive Wear: Often due to poor lubrication.

Noise and Vibration: Usually indicates contamination or damage.

Overheating: Result of high load or lack of lubrication.

Most of these problems can be prevented with proactive care.

Choosing the Right Linear Rail Bearing

When selecting a bearing:

Consider load capacity, speed, and precision needs.

Check industry standards for quality assurance.

Balance cost and performance for long-term ROI.

Making the wrong choice can lead to inefficiency and higher costs.

Innovations in Linear Rail Bearing

Modern advancements are reshaping this field:

Self-Lubricating Bearings: Reduce maintenance needs.

Smart Sensors: Monitor performance in real-time.

Lightweight Materials: Improve energy efficiency in robotics.

These innovations make bearings smarter, more reliable, and sustainable.

Future Trends of Linear Rail Bearing

Looking ahead, the future is exciting:

AI-Driven Predictive Maintenance: Early fault detection reduces downtime.

Eco-Friendly Materials: Reduces environmental footprint.

Miniaturization: Critical for medical and micro-robotics applications.

Linear rail bearings are set to become even more efficient and sustainable.

Cost of Linear Rail Bearing

Costs depend on:

Material and Size: Larger bearings cost more.

Type: Roller bearings are pricier than ball-type.

Customization: Special coatings or tolerances add cost.

While initial investment may be high, their durability ensures excellent ROI.

Top Manufacturers of Linear Rail Bearing

Some global leaders include:

THK (Japan): Known for precision.

HIWIN (Taiwan): Affordable and reliable.

Bosch Rexroth (Germany): High-performance industrial solutions.

NSK (Japan): Durable designs for heavy loads.

These companies set benchmarks in the industry.

Linear Rail Bearing in Automation

In Industry 4.0, linear rail bearings are vital:

Support robotic arms for smart factories.

Enable automation precision in packaging and assembly.

Improve productivity and reduce errors.

Without them, automation efficiency would drop significantly.

Environmental Impact of Linear Rail Bearing

Environmental considerations include:

Energy Efficiency: Reduced friction lowers energy consumption.

Recyclability: Many bearings are made from recyclable metals.

Sustainable Manufacturing: Growing focus on green production processes.

This ensures bearings remain eco-friendly while serving industrial needs.

Safety Considerations with Linear Rail Bearing

For safe usage:

Handle bearings with care to avoid contamination.

Follow safety standards like ISO and ANSI.

Reduce risks with proper installation and regular checks.

Negligence in safety can cause equipment failure and accidents.

Case Studies of Linear Rail Bearing

CNC Industry: Improved cutting precision by 40%.

Robotics: Increased repeatability in robotic arms.

Aerospace: Enhanced flight simulator accuracy.

These case studies prove the real-world impact of linear rail bearings.

Linear Rail Bearing Maintenance Tools

Specialized Lubricants: Extend bearing life.

Alignment Kits: Ensure precise installation.

Vibration Analyzers: Detect early-stage issues.

These tools make maintenance easier and more effective.

Troubleshooting Linear Rail Bearing Issues

When problems arise:

Diagnose Faults: Identify misalignment or contamination.

Quick Fixes: Re-lubrication or realignment often helps.

Replacement: When damage is severe, replacement is the only option.

Quick troubleshooting prevents costly downtime.

Linear Rail Bearing Lifespan

Longevity depends on:

Proper installation and lubrication.

Avoiding overload conditions.

Regular preventive maintenance.

On average, a high-quality bearing lasts 8–10 years in industrial use.

Linear Rail Bearing

To sum it up, a linear rail bearing is an essential mechanical component enabling precise, smooth, and efficient linear motion. Its applications span robotics, CNC, aerospace, and more, making it a vital part of modern technology.

Frequently Asked Questions

What is a linear rail bearing used for?

It is used to enable smooth linear motion in machines like CNCs, robots, and medical devices.

How long does a linear rail bearing last?

With proper maintenance, they can last 8–10 years or more.

Which type of linear rail bearing is best?

Ball-type is most common, but roller-type is better for heavy loads.

How do I maintain a linear rail bearing?

Regular lubrication, cleaning, and alignment checks are essential.

Can linear rail bearings be customized?

Yes, manufacturers often customize size, coating, and materials.

Are linear rail bearings expensive?

They vary in cost, but long-term efficiency makes them cost-effective.

Conclusion

Linear rail bearings are the unsung heroes of precision engineering. They ensure machines operate with speed, accuracy, and durability. From CNC machines to aerospace applications, their role is unmatched. With innovations like smart sensors and eco-friendly materials, the future of linear rail bearings looks promising.

Investing in the right bearing means improved efficiency, reduced downtime, and long-term savings—making them indispensable in modern industries.

Suggestions for Inbound Links

Link to articles on CNC machining

Link to guides on robotics components

Link to maintenance best practices pages