Introduction

Machine rails, also known as linear rails or guide rails, are essential components in modern industrial machinery, automation systems, and precision equipment. They provide reliable and accurate linear motion, enabling machines to perform tasks with high repeatability, precision, and efficiency. From CNC machines and robotic arms to 3D printers and inspection equipment, machine rails play a pivotal role in a wide range of industrial and commercial applications.

This comprehensive guide explores the types, mechanics, materials, design considerations, applications, installation, maintenance, troubleshooting, and emerging trends in machine rails. It is intended to serve as a complete resource for engineers, designers, and industry professionals seeking in-depth knowledge.

Table of Contents

What Are Machine Rails?

Components of a Machine Rail System

Types of Machine Rails

Mechanics and Design Principles

Materials Used in Machine Rails

Advantages of Machine Rails

Applications Across Industries

Selecting the Right Machine Rail

Installation and Alignment Techniques

Maintenance and Lubrication

Common Issues and Troubleshooting

Emerging Trends and Innovations

Frequently Asked Questions (FAQs)

Conclusion

1. What Are Machine Rails?

Machine rails are precision-engineered linear tracks that allow components of a machine to move smoothly along a straight path. Unlike simple sliding mechanisms, machine rails often incorporate rolling elements such as balls or rollers to reduce friction, improve accuracy, and enable the system to carry heavier loads. These rails are crucial in applications where precise linear motion is required, including industrial automation, robotics, CNC machining, and medical devices.

Machine rails are also referred to as linear rails, linear guideways, or linear guide rails, depending on their design and usage. They serve as the foundation for linear motion systems and are designed to withstand various types of loads, including axial, radial, and moment forces.

2. Components of a Machine Rail System

A complete machine rail system typically includes several essential components:

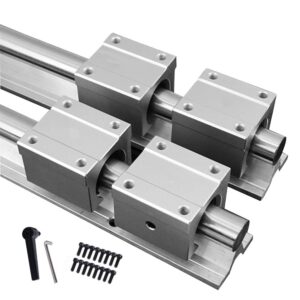

2.1 Rail

The rail is the fixed track along which the moving carriage or block travels. Rails are precisely manufactured to ensure minimal deflection and high accuracy. Rails may be straight, curved, or custom-shaped depending on the application.

2.2 Carriage (Slider or Block)

The carriage, also known as the slider block, moves along the rail and carries the load. It houses rolling elements or sliding surfaces and may incorporate integrated lubrication channels, seals, and protective covers.

2.3 Rolling Elements

Rolling elements, such as balls or cylindrical rollers, reduce friction and allow smooth movement. Recirculating designs allow continuous operation over long distances.

2.4 End Caps and Covers

End caps prevent rolling elements from escaping and protect the system from contaminants, dust, and debris.

2.5 Lubrication Features

Lubrication channels, reservoirs, or wicks help maintain smooth motion and extend the life of the rail system.

3. Types of Machine Rails

Machine rails come in various types depending on the design, load capacity, and application requirements:

3.1 Ball-Type Linear Rails

Design: Uses recirculating balls to minimize friction.

Applications: CNC machinery, automation systems, 3D printers.

Advantages: Smooth motion, moderate load capacity, high precision.

3.2 Roller-Type Linear Rails

Design: Cylindrical or needle rollers distribute loads over a larger contact area.

Applications: Heavy industrial machinery, press equipment.

Advantages: High load capacity, long service life.

3.3 Cross-Roller Rails

Design: Rollers are arranged in a cross pattern to handle multi-directional loads.

Applications: Precision robotics, medical devices, inspection systems.

Advantages: Supports radial, axial, and moment loads simultaneously.

3.4 Miniature Linear Rails

Design: Compact rails for small-scale applications.

Applications: Laboratory instruments, small automation systems.

Advantages: High precision in limited spaces.

3.5 Plain (Sliding) Rails

Design: Low-friction sliding surfaces without rolling elements.

Applications: Light machinery, low-speed operations.

Advantages: Simple, cost-effective, minimal maintenance.

4. Mechanics and Design Principles

4.1 Load Distribution

Machine rails are engineered to distribute loads evenly across rolling elements or sliding surfaces, preventing localized wear and maintaining system longevity.

4.2 Friction Reduction

Rolling elements or low-friction sliding surfaces reduce energy loss, heat generation, and wear, enabling smoother and more efficient motion.

4.3 Rigidity and Accuracy

High-quality machine rails maintain rigidity under heavy loads, ensuring precise positioning and minimal deflection.

4.4 Recirculation Mechanism

In ball-type and roller-type rails, recirculating elements provide continuous motion and prevent jamming, allowing extended travel distances.

4.5 Preload

Preloading removes clearance between the carriage and rail, improving stiffness, reducing vibration, and enhancing positional accuracy.

5. Materials Used in Machine Rails

5.1 Hardened Steel

Offers excellent strength and wear resistance, suitable for heavy-duty applications.

5.2 Stainless Steel

Provides corrosion resistance in humid or chemically aggressive environments while maintaining strength.

5.3 Aluminum

Lightweight and corrosion-resistant, ideal for portable machinery or aerospace applications.

5.4 Polymers and Composites

Used for cages, seals, and low-friction coatings to reduce noise, friction, and maintenance requirements.

6. Advantages of Machine Rails

Precision: Enables high positional accuracy for automation and machining.

Smooth Motion: Minimal friction and vibration improve performance.

High Load Capacity: Supports axial, radial, and moment loads efficiently.

Durability: Long service life with proper maintenance.

Versatility: Suitable for industrial, robotic, and medical applications.

Noise Reduction: Quiet operation due to rolling elements or advanced sliding surfaces.

7. Applications Across Industries

7.1 CNC Machines

Provide precise linear motion for cutting heads, milling tables, and engraving systems.

7.2 Robotics

Enable accurate and smooth movement of robotic arms and automated assembly systems.

7.3 Industrial Automation

Used in conveyors, assembly lines, and inspection machinery for repeatable motion.

7.4 Medical Equipment

Support linear motion in imaging systems, surgical robots, and laboratory automation devices.

7.5 Semiconductor Manufacturing

Critical for precise wafer handling, assembly, and inspection.

7.6 Aerospace and Defense

Provide precise positioning for simulators, satellite mechanisms, and instrumentation.

8. Selecting the Right Machine Rail

Factors to consider:

Load Requirements: Ensure compatibility with both static and dynamic loads.

Precision: Evaluate positional accuracy and repeatability requirements.

Speed: Choose a rail suitable for desired operational speeds.

Environmental Conditions: Consider temperature, humidity, and contamination levels.

Space Constraints: Select rail and carriage dimensions suitable for the system.

Maintenance Requirements: Evaluate lubrication intervals and accessibility.

9. Installation and Alignment Techniques

9.1 Surface Preparation

Ensure the mounting surface is flat, rigid, and free of debris to prevent misalignment.

9.2 Rail Alignment

Rails must be parallel and straight; misalignment increases friction, reduces accuracy, and accelerates wear.

9.3 Mounting

Use proper fasteners and torque specifications to avoid rail deformation.

9.4 Testing

Conduct load and motion tests to verify smooth travel and accuracy.

10. Maintenance and Lubrication

Cleaning: Regularly remove dust, debris, and contaminants.

Lubrication: Apply grease or oil according to manufacturer specifications.

Inspection: Check for wear, corrosion, and damage.

Replacement: Replace worn or damaged components to maintain optimal performance.

11. Common Issues and Troubleshooting

Noise or Vibration: Often caused by misalignment, debris, or insufficient lubrication.

Sticking or Jamming: Check for bent rails, damaged rolling elements, or foreign particles.

Excessive Wear: Results from overloading, poor lubrication, or contamination.

Corrosion: Use stainless steel or coated rails in humid or chemically aggressive environments.

12. Emerging Trends and Innovations

High-Speed Rails: Designed for ultra-fast production machinery.

Miniaturized Rails: Compact guides for precision instruments and small automation systems.

Integrated Sensors: Real-time monitoring of position, load, and temperature.

Advanced Materials: Use of ceramics, coatings, and polymers to reduce friction and extend life.

Predictive Maintenance: IoT-enabled rails allow early detection of wear or operational issues.

13. Frequently Asked Questions (FAQs)

Q1: What is the difference between machine rails and conventional linear bearings?

A1: Machine rails provide precise linear motion using rolling or low-friction elements, while conventional linear bearings are simpler and often less precise.

Q2: Can machine rails be used outdoors?

A2: Yes, stainless steel or corrosion-resistant rails are suitable for outdoor or harsh environments.

Q3: How often should machine rails be lubricated?

A3: Depending on load and operating conditions, lubrication may be needed weekly, monthly, or per manufacturer guidance.

Q4: What is the typical lifespan of a machine rail?

A4: With proper maintenance, machine rails can last several years, even in heavy-duty industrial applications.