Outline for “Linear Guide with Motor”

| Main Headings | Sub-Headings |

|---|---|

| Introduction to Linear Guide with Motor | What It Means, Why It Matters |

| Linear Guide with Motor | Core Concept, How It Combines Guidance and Power |

| How Linear Guide with Motor Works | Rail, Carriage, Motor Integration, Motion Control |

| Types of Motors Used in Linear Guides | Stepper Motors, Servo Motors, DC Motors |

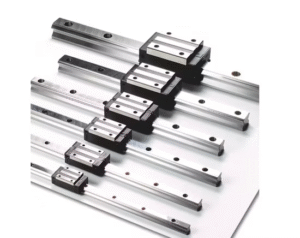

| Key Components of Linear Guide with Motor | Rails, Bearings, Carriage, Motor, Controller |

| Advantages of Linear Guide with Motor | Precision, Compact Design, Energy Savings, Versatility |

| Challenges of Linear Guide with Motor | Higher Costs, Maintenance, Technical Complexity |

| Applications of Linear Guide with Motor | CNC Machines, Robotics, Medical Equipment, Packaging Industry, Semiconductor Manufacturing |

| Installation of Linear Guide with Motor | Mounting, Motor Wiring, Alignment, Calibration |

| Maintenance of Linear Guide with Motor | Lubrication, Electrical Inspection, Monitoring |

| Linear Guide with Motor vs Traditional Linear Guides | Efficiency, Cost, Performance |

| Innovations in Linear Guide with Motor | Smart Sensors, AI Motion Control, Integrated Drives |

| Choosing the Right Linear Guide with Motor | Load, Speed, Precision, Environment |

| Top Manufacturers | Hiwin, THK, NSK, Bosch Rexroth, Parker Hannifin |

| Future of Linear Guide with Motor | IoT Integration, Predictive Maintenance, Sustainability |

| Cost and ROI Analysis | Upfront Investment vs Long-Term Benefits |

| Safety Considerations | Overload Protection, Emergency Stops, Safe Wiring |

| Case Studies of Linear Guide with Motor | Robotics, Aerospace, Medical Imaging |

| Frequently Asked Questions | Six FAQs with Detailed Answers |

| Conclusion | Final Thoughts on Linear Guide with Motor |

Introduction to Linear Guide with Motor

Modern automation thrives on accuracy, speed, and compactness. Machines that once required bulky mechanisms can now deliver flawless movements with reduced footprints. One technology at the center of this shift is the linear guide with motor.

This system merges two critical components—guidance and drive. Traditionally, rails handled linear movement while external belts, pulleys, or screw drives powered motion. By integrating the motor directly with the linear guide, industries now enjoy higher precision, simpler setups, and more reliable performance.

From CNC machines to robotic arms, and from medical imaging to packaging lines, linear guides with motors are revolutionizing how motion is achieved in modern industry.

Linear Guide with Motor

A linear guide with motor is a motion system that combines a rail-and-carriage guiding mechanism with a built-in motor drive. The motor, often a servo or stepper type, directly powers the carriage’s movement along the rail.

This integration eliminates unnecessary components, making the system compact, faster to install, and easier to maintain. The design also improves synchronization, ensuring that motion is more predictable and controllable.

In industries where microns matter, this synergy ensures both accuracy and efficiency.

How Linear Guide with Motor Works

Understanding how these systems function helps reveal why they’re growing so quickly in demand.

Rail: Provides the linear pathway for the carriage.

Carriage: Holds the load and slides along the rail.

Motor Integration: The motor, either attached directly or embedded within the carriage, drives the motion.

Motion Control: An external controller manages input signals, regulating speed, acceleration, and stopping points.

The result is a streamlined process that reduces vibration, increases lifespan, and enhances operational performance.

Types of Motors Used in Linear Guides

The motor type determines system performance.

Stepper Motors

Operate in discrete steps, ensuring precise positioning.

Cost-effective and reliable.

Ideal for low to medium-load automation systems.

Servo Motors

Offer closed-loop control with feedback systems.

Capable of high-speed, high-accuracy movement.

Widely used in robotics, CNC, and aerospace.

DC Motors

Simple and robust design.

Great for continuous, low-cost applications.

Common in packaging, material handling, and lightweight robotics.

Choosing the right motor depends on balancing cost, speed, and required accuracy.

Key Components of Linear Guide with Motor

A well-functioning system requires seamless coordination of components:

Rails: Hardened steel or alloy tracks provide precise pathways.

Bearings: Reduce friction and support smooth load movement.

Carriage: The load-bearing unit that integrates with the motor.

Motor: The driving force behind movement.

Controller: Manages motion instructions and feedback.

Sensors (Optional): Ensure position accuracy and prevent overloads.

Each part plays a distinct role, and together they make linear guides with motors powerful automation tools.

Advantages of Linear Guide with Motor

The popularity of these systems is driven by their clear benefits:

Compact Design: Eliminates belts, screws, and pulleys.

Higher Precision: Direct motor control reduces errors.

Energy Efficiency: Lower friction and smarter motion save energy.

Easy Installation: Fewer components mean faster setup.

Reduced Maintenance: Less wear on parts leads to longer lifespans.

Versatility: Suitable for a range of industries, from robotics to healthcare.

These qualities make them indispensable in today’s competitive industrial landscape.

Challenges of Linear Guide with Motor

Despite their strengths, there are some hurdles:

Cost: Higher initial investment compared to traditional rails.

Technical Complexity: Requires skilled setup and calibration.

Maintenance: Motors demand periodic inspection and lubrication.

Environmental Sensitivity: Dust, vibration, and extreme temperatures can reduce performance.

For high-value industries, however, the trade-off is well worth the long-term benefits.

Applications of Linear Guide with Motor

The adoption of these systems spans multiple industries:

CNC Machines: Enable high-speed, vibration-free cutting.

Robotics: Ensure precise, repeatable robotic arm movements.

Medical Equipment: Essential for imaging machines, surgical robots, and lab automation.

Packaging Industry: Boosts speed and accuracy in assembly lines.

Semiconductor Manufacturing: Supports micron-level precision for chip placement.

Whether handling microchips or airplane parts, these systems adapt to vastly different demands.

Installation of Linear Guide with Motor

Proper installation ensures peak performance.

Preparation: Clean rails and check motor housing.

Mounting: Secure rail onto a flat, rigid base.

Motor Wiring: Connect motor to the controller with correct specifications.

Alignment: Verify rail straightness and carriage movement.

Calibration: Program controller for motion sequences.

A poorly aligned system can reduce lifespan and compromise accuracy.

Maintenance of Linear Guide with Motor

While these systems are durable, upkeep is necessary:

Lubrication: Regularly apply grease or oil as recommended.

Electrical Inspection: Check wiring, sensors, and controllers.

Cleaning: Remove dust, debris, and coolant buildup.

Monitoring: Use diagnostic software for predictive maintenance.

Preventive care helps avoid costly breakdowns.

Linear Guide with Motor vs Traditional Linear Guides

Traditional Guides rely on external ball screws or belts for motion, increasing system size and complexity.

Linear Guide with Motor integrates drive and motion, saving space and improving synchronization.

Efficiency: Integrated systems consume less power.

Cost: Higher upfront, but lower long-term maintenance.

Performance: Superior speed, accuracy, and reliability.

For precision-driven industries, integrated designs are the future.

Innovations in Linear Guide with Motor

Technology continues to evolve:

Smart Sensors: Provide real-time data on wear and performance.

AI Motion Control: Adaptive systems that learn and optimize movements.

Integrated Drives: All-in-one designs with controller and motor in a compact package.

Noise Reduction: Enhanced materials and designs for quieter operation.

These breakthroughs push the boundaries of what’s possible in automation.

Choosing the Right Linear Guide with Motor

Key considerations before investing:

Load Capacity: Match system strength with application demands.

Speed Requirements: Higher speeds may need servo-driven designs.

Precision Needs: Semiconductor and medical fields demand micron-level accuracy.

Environment: Dusty, wet, or high-vibration settings may need sealed systems.

Budget: Balance initial costs with long-term savings.

The right choice ensures efficiency, reliability, and ROI.

Top Manufacturers

Leading global suppliers include:

Hiwin – Known for reliable, cost-effective automation solutions.

THK – Pioneers in advanced motion technologies.

NSK – Focused on durability and high-load applications.

Bosch Rexroth – Offers integrated automation systems worldwide.

Parker Hannifin – Specializes in custom-engineered solutions.

Working with trusted brands guarantees quality and support.

Future of Linear Guide with Motor

The next decade will see:

IoT Integration: Systems that self-monitor and report issues.

Predictive Maintenance: Early fault detection with AI diagnostics.

Eco-Friendly Designs: Lightweight, sustainable materials.

Hybrid Systems: Combining linear drives with rotary functions.

Future-proofing automation requires embracing these advances.

Cost and ROI Analysis

Though pricier upfront, linear guides with motors save money over time:

Initial Investment: Higher than basic linear rails.

Operational Savings: Reduced downtime, lower energy use.

ROI Timeline: Typically within 1–3 years, depending on industry.

For companies where uptime equals profit, the ROI is compelling.

Safety Considerations

Safety must always come first:

Overload Protection: Prevents damage from excessive force.

Emergency Stops: Integrated systems for sudden shutdowns.

Proper Wiring: Reduces risks of short circuits or fire.

Alignment Checks: Prevents mechanical failure and accidents.

Following safety protocols ensures reliability and worker protection.

Case Studies of Linear Guide with Motor

Robotics: A factory using servo-driven linear guides improved assembly line speed by 30%.

Aerospace: Linear guides with motors reduced vibration in machining jet engine components.

Medical Imaging: MRI systems used linear guides with motors for patient positioning, improving scan accuracy.

These real-world examples highlight the versatility of the technology.

Frequently Asked Questions

What is a linear guide with motor?

It’s a motion system that integrates a motor with a linear rail and carriage for compact, precise automation.

Which motor is best for linear guides?

Servo motors are ideal for high precision, while stepper motors suit cost-effective applications.

Do linear guides with motors need lubrication?

Yes, bearings and rails require lubrication, while motors need periodic inspection.

Are they expensive?

They cost more initially but save money through efficiency and reduced maintenance.

Can they be used in medical devices?

Yes, they’re widely used in surgical robots, imaging systems, and lab automation.

What industries use linear guides with motors?

CNC machining, robotics, aerospace, packaging, healthcare, and semiconductor manufacturing.

Conclusion

The linear guide with motor represents a new era in motion technology. By merging guiding precision with integrated motor power, industries gain compact, efficient, and accurate solutions.

Though the upfront investment is higher, the long-term benefits—higher uptime, lower energy use, and consistent precision—make them indispensable for future automation.

As innovations like AI-driven control and IoT monitoring become standard, linear guides with motors will only grow in importance. For industries where accuracy is non-negotiable, this technology is not just a choice—it’s the future.

Inbound Link Suggestions

Article on Linear Motion Rails for system comparisons.

Post on Linear Bearing and Rail for alternative motion solutions.