Outline for Long-Form Article: Linear Bearing Carriage

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Linear Bearing Carriage | Importance in precision motion, Applications overview |

| What is a Linear Bearing Carriage? | Definition, Purpose, Difference from linear guide carriage |

| History of Linear Bearing Systems | Early designs, Evolution with industrial needs |

| Core Components of Linear Bearing Carriage | Rail, Carriage body, Bearing elements, Seals |

| Types of Linear Bearing Carriage | Ball-type, Roller-type, Miniature, Flanged |

| Materials Used in Linear Bearing Carriage | Stainless steel, Alloy steel, Coatings |

| Working Principle of Linear Bearing Carriage | Rolling mechanism, Load distribution |

| Advantages of Linear Bearing Carriage | Accuracy, Smooth motion, Durability |

| Disadvantages and Limitations | Cost, Alignment, Maintenance requirements |

| Applications of Linear Bearing Carriage | CNC, Robotics, Medical, Aerospace, Automotive |

| Comparison with Other Linear Motion Systems | Bushings vs bearings, Carriages vs blocks |

| Load Capacity and Performance | Static load, Dynamic load, Shock resistance |

| Accuracy and Precision | Repeatability, Positioning accuracy |

| Maintenance of Linear Bearing Carriage | Lubrication, Cleaning, Wear inspection |

| Common Problems and Troubleshooting | Noise, Misalignment, Contamination |

| Installation Process | Mounting, Alignment, Preload adjustment |

| Innovations in Linear Bearing Carriage | Smart systems, Nano-coatings, Lightweight designs |

| Cost Considerations | Pricing, Long-term value |

| How to Choose the Right Linear Bearing Carriage | Load, Speed, Environment |

| Future Trends in Industry 4.0 | Smart monitoring, Predictive maintenance |

| Environmental Impact and Sustainability | Eco-friendly lubricants, Recycling |

| Leading Manufacturers | Global brands, Specialized producers |

| Case Studies of Linear Bearing Carriage | Aerospace, Semiconductor, Packaging |

| Conclusion | Final thoughts |

| FAQs about Linear Bearing Carriage | Six most common questions with answers |

Introduction to Linear Bearing Carriage

In the world of industrial automation and precision machinery, the linear bearing carriage is a cornerstone technology. It enables smooth, accurate, and reliable movement along a straight path. Without it, systems like CNC machines, robotic arms, and semiconductor manufacturing equipment would struggle to achieve the precision and consistency demanded in modern production.

Linear bearing carriages are designed to minimize friction, distribute load efficiently, and withstand heavy usage. As industries move toward Industry 4.0 and smart manufacturing, these carriages play a critical role in ensuring machines operate at peak performance, with fewer errors and longer service lives.

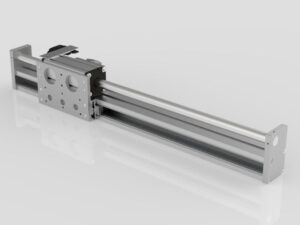

What is a Linear Bearing Carriage?

A linear bearing carriage is a motion component that allows a load to travel along a rail with minimal friction. Unlike sliding systems, which rely on surface contact, a bearing carriage uses rolling elements such as balls or rollers to enable smooth travel.

Its main functions include:

Supporting loads in multiple directions.

Providing smooth, low-friction travel.

Maintaining high accuracy and repeatability.

The linear bearing carriage differs from a linear guide carriage primarily in the design of its rolling elements and the way it handles loads. While the terms are often used interchangeably, linear bearing carriages tend to emphasize the rolling element mechanism, ensuring superior smoothness in motion.

History of Linear Bearing Systems

The development of linear bearing carriages follows humanity’s ongoing quest to reduce friction in motion. Ancient builders used lubricated slides and rollers for moving heavy loads. These methods were effective but crude.

The Industrial Revolution introduced hardened steels and precision machining, which allowed for the creation of more refined bearings. The introduction of recirculating ball bearings in the mid-20th century marked a major leap forward. These innovations paved the way for today’s high-precision linear bearing carriages, which are capable of micrometer-level accuracy.

Modern designs incorporate advanced materials, nano-coatings, and even sensor technology that allows monitoring of wear and performance in real-time.

Core Components of Linear Bearing Carriage

Despite its compact size, a linear bearing carriage contains multiple precision components:

Rail: The hardened steel track that defines the movement path.

Carriage Body: The main structure housing the rolling elements.

Bearing Elements: Steel balls or cylindrical rollers that circulate within the carriage, minimizing friction.

Seals: Prevent contaminants like dust and fluids from entering, while retaining lubrication.

End Caps: Guide rolling elements back into circulation smoothly.

Each component must be precisely engineered to ensure reliability and long service life. Even the smallest imperfection can lead to vibration, noise, or premature wear.

Types of Linear Bearing Carriage

The linear bearing carriage comes in multiple configurations to meet specific requirements across different industries. Each type has unique advantages, and the right choice depends on load, precision, and space constraints.

Ball-Type Carriage:

Uses recirculating steel balls that provide smooth, low-friction motion. This type is the most common, offering excellent precision and speed, making it suitable for CNC machines and robotics.Roller-Type Carriage:

Instead of balls, cylindrical rollers are used. This design increases surface contact, providing higher rigidity and load capacity. Roller-type carriages are ideal for heavy-duty applications where deflection must be minimized.Miniature Carriage:

Compact and lightweight, miniature carriages are found in medical devices, semiconductor equipment, and electronics. They provide exceptional precision in tight spaces.Flanged Carriage:

Features an extended flange base for easier mounting and greater stability. These are often used in machinery where high rigidity and secure installation are critical.

Choosing between these types involves balancing precision, rigidity, size, and cost based on the application’s specific needs.

Materials Used in Linear Bearing Carriage

The material selection for a linear bearing carriage greatly influences its strength, lifespan, and resistance to environmental conditions.

Stainless Steel:

Offers excellent corrosion resistance, making it ideal for cleanroom environments, food production, and medical equipment.Alloy Steel:

Known for its toughness and wear resistance, alloy steel is a common choice in heavy-duty industrial applications.Ceramic or Hybrid Bearings:

Sometimes rolling elements are made of ceramics or hybrid materials, offering lighter weight, higher speed capabilities, and extended durability.Protective Coatings:

Surfaces may be treated with black oxide, nickel plating, or chrome coatings to resist corrosion, dust, and moisture.

The right material not only extends service life but also ensures reliable performance in harsh or sensitive environments.

Working Principle of Linear Bearing Carriage

The linear bearing carriage operates on a rolling mechanism rather than sliding contact. Rolling elements inside the carriage continuously circulate as it moves along the rail.

Here’s how it works:

Load Support: Rolling elements in contact with the rail bear the load, distributing it evenly.

Rolling Motion: As the carriage advances, balls or rollers rotate instead of sliding, drastically reducing friction.

Recirculation: Once rolling elements pass through the load zone, they are guided back to the start via return paths inside the carriage.

Continuous Operation: This cycle repeats seamlessly, enabling smooth and precise motion.

This principle ensures that the carriage can handle high loads while maintaining long-term durability and accuracy, even in high-speed applications.

Advantages of Linear Bearing Carriage

The linear bearing carriage has gained wide adoption due to its numerous advantages:

High Precision: Delivers micrometer-level accuracy, crucial for CNC and semiconductor manufacturing.

Smooth Motion: Rolling friction provides stable, vibration-free operation.

Load Capacity: Capable of supporting heavy static and dynamic loads.

Durability: Advanced designs withstand years of high-speed use.

Noise Reduction: Operates more quietly compared to sliding mechanisms.

Low Maintenance: Sealed and pre-lubricated options minimize the need for frequent servicing.

These benefits make linear bearing carriages indispensable in industries that require reliability and repeatability in motion.

Disadvantages and Limitations

While powerful, linear bearing carriages do come with a few limitations:

Cost: They are more expensive than simple linear bushings or shafts.

Alignment Sensitivity: Improper mounting or uneven surfaces can lead to premature wear and failure.

Environmental Factors: Dust, dirt, and moisture can damage rolling elements if seals are compromised.

Overengineering Risks: In low-precision or lightweight applications, simpler and cheaper alternatives may be more practical.

Understanding these limitations ensures that carriages are deployed only where their benefits outweigh the added cost and complexity.

Applications of Linear Bearing Carriage

Linear bearing carriages are used across a wide spectrum of industries due to their versatility and reliability:

CNC Machines: Provide precise tool and workpiece movement, ensuring high-quality machining.

Robotics: Enable smooth and repeatable arm and actuator motion.

Medical Equipment: Found in imaging systems, lab automation, and surgical robots.

Aerospace: Used for precise positioning in assembly and testing systems.

Automotive Industry: Support assembly lines, inspection systems, and component manufacturing.

Packaging & Printing: Deliver high-speed, repetitive motion with accuracy.

From heavy-duty aerospace machinery to delicate medical devices, linear bearing carriages play a crucial role in enabling precision engineering.

Comparison with Other Linear Motion Systems

To understand the strengths of a linear bearing carriage, it’s helpful to compare it with other motion systems:

Linear Bushings and Shafts:

These use sliding contact, making them inexpensive and simple. However, they create more friction, wear faster, and lack the precision of bearing carriages.Plain Bearings:

Suitable for low-load or low-precision applications, plain bearings are cost-effective but cannot match the smoothness and load capacity of rolling systems.Linear Guide Blocks vs Carriages:

A linear guide block and a linear bearing carriage are closely related but not identical. The carriage focuses on the bearing mechanism itself, while the block may be part of a broader rail system. Carriages are generally more refined in handling loads and ensuring smooth rolling.

In short, linear bearing carriages outperform alternatives when accuracy, durability, and repeatability are priorities.

Load Capacity and Performance

One of the defining features of a linear bearing carriage is its ability to handle significant loads while maintaining precision. Performance is typically measured in three categories:

Static Load Capacity:

The maximum weight a carriage can bear while stationary without deformation or damage.Dynamic Load Capacity:

The maximum load it can carry while in continuous motion over its service life.Moment Load Resistance:

The ability to resist tilting or twisting forces acting on the carriage.

Engineers select carriages based on these parameters to ensure systems run smoothly without premature wear. For heavy-duty applications such as aerospace assembly or automotive testing, roller-type carriages often outperform ball-type ones due to their rigidity and surface contact.

Accuracy and Precision

The accuracy of linear bearing carriages makes them indispensable in high-tech industries. Their benefits include:

Positioning Accuracy: Carriages provide micrometer-level travel accuracy, essential in CNC machining and optical devices.

Repeatability: They maintain consistency over repeated cycles, ensuring reliable manufacturing outcomes.

Straightness of Motion: With proper installation, motion stays true to the rail path, minimizing deviations.

These qualities explain why industries like semiconductor manufacturing and medical device production rely heavily on linear bearing carriages.

Maintenance of Linear Bearing Carriage

Although many models are designed for low-maintenance use, proper care extends the life of a linear bearing carriage:

Lubrication: Applying grease or oil reduces friction and wear. Many modern carriages are pre-lubricated.

Cleaning: Removing dust, chips, or other contaminants prevents damage to rolling elements.

Inspection: Regular checks for noise, vibration, or uneven movement help identify issues early.

Seal Replacement: Damaged seals should be replaced promptly to protect the carriage’s interior.

With a solid maintenance schedule, carriages can last years, even in demanding conditions.

Common Problems and Troubleshooting

Despite their precision, linear bearing carriages may encounter issues. Common problems include:

Noise or Vibration: Often caused by contamination or insufficient lubrication.

Misalignment: Poor mounting surfaces or incorrect installation can lead to uneven load distribution.

Contamination: Dust, dirt, or fluids can damage the rolling mechanism if seals are compromised.

Wear and Deformation: Overloading or extended use without maintenance may shorten service life.

Solutions often involve cleaning, re-lubrication, or re-alignment. For severe damage, replacement may be more cost-effective than repair.

Installation Process

Proper installation is critical to ensure a linear bearing carriage performs as designed. The process typically involves:

Mounting: Secure the rail to a flat, rigid surface to prevent deflection.

Alignment: Ensure rails are parallel and aligned to avoid stress on the carriage.

Preload Adjustment: Some systems allow preload tuning to eliminate play and increase rigidity.

Testing: Move the carriage manually to check for smooth travel before powering the system.

Even the most advanced carriage will fail if installed on an uneven or improperly prepared surface. Precision installation is as important as the component itself.

Innovations in Linear Bearing Carriage

Recent years have seen exciting innovations in linear bearing carriage technology:

Smart Carriages: Equipped with embedded sensors that monitor vibration, wear, and lubrication levels.

Advanced Coatings: Nano-coatings reduce friction, resist corrosion, and extend service life.

Lightweight Designs: Aluminum and composite materials help reduce system weight without sacrificing strength.

Self-Lubricating Systems: Built-in reservoirs release lubricant gradually, reducing maintenance needs.

These innovations align with the needs of Industry 4.0, where predictive maintenance and efficiency are top priorities.