Outline for the Long-Form Article on “Ball Bearing Linear”

| Section | Subtopics |

|---|---|

| Introduction | Overview of ball bearing linear motion systems and their industrial importance |

| Understanding Ball Bearing Linear Systems | Definition, structure, and working principles |

| Core Components of Ball Bearing Linear Assemblies | Rail, carriage, ball elements, cage, and seals |

| How Ball Bearing Linear Mechanisms Work | Rolling motion and friction reduction explained |

| Types of Ball Bearing Linear Systems | Different styles based on load, shape, and application |

| Ball Bearing Linear vs Roller Bearing Linear | Detailed comparison of performance and use cases |

| Key Benefits of Ball Bearing Linear Systems | Precision, stability, low noise, and long lifespan |

| Applications of Ball Bearing Linear Systems | Industries using these systems for smooth motion |

| Ball Bearing Linear in CNC Machines | Role in accuracy and high-speed operation |

| Ball Bearing Linear in Robotics | Contribution to flexibility and consistent movement |

| Selecting the Right Ball Bearing Linear System | Considerations for engineers and machine designers |

| Installation and Alignment Techniques | How to install for maximum efficiency |

| Lubrication and Maintenance Guidelines | Keeping ball bearing linear systems in top condition |

| Common Issues and Troubleshooting Tips | Noise, wear, and misalignment problems solved |

| Material Options for Ball Bearing Linear Components | Stainless steel, chrome steel, and hybrid ceramics |

| Design Innovations in Ball Bearing Linear Technology | Modern improvements for efficiency and load capacity |

| YH Linear Ball Bearing Linear Solutions | Introduction to YH Linear’s expertise and product line |

| Why Choose YH Linear for Ball Bearing Linear Systems | Reliability, quality, and precision engineering |

| Manufacturing Standards at YH Linear | Quality testing, tolerances, and certifications |

| Global Applications of YH Linear Ball Bearing Systems | Export markets and customer success stories |

| YH Linear’s Sustainable Production Practices | Eco-friendly engineering and resource optimization |

| Customer Support and Customization Options | OEM/ODM solutions from YH Linear Motion Systems |

| Frequently Asked Questions | Six common queries with practical answers |

| Conclusion | Summary of benefits and final brand invitation |

| Suggested Inbound and Outbound Links | Internal and external SEO-friendly resources |

Ball Bearing Linear

A ball bearing linear system is a key element in precision machinery, designed to deliver smooth, accurate, and friction-free motion along a straight path. From CNC machining centers to automated robotics, this motion system ensures consistent performance and extended component lifespan.

YH Linear Motion Systems (https://yhlinear.com/) stands as a global manufacturer and innovator in linear motion technology. Their ball bearing linear solutions are engineered to meet the demands of modern industries that require high precision, reliability, and durability.

Understanding Ball Bearing Linear Systems

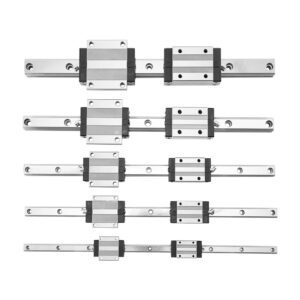

A ball bearing linear system consists of a linear rail and a carriage (or block) that moves along it using rows of precision steel balls. These balls roll between the rail and block, minimizing friction and enabling high-speed, accurate linear motion.

Unlike sliding bearings, which rely on surface contact, ball bearing linear mechanisms utilize rolling contact—significantly reducing wear and energy loss. The design ensures smoother travel, less noise, and consistent alignment across long operational periods.

Core Components of Ball Bearing Linear Assemblies

A typical ball bearing linear system includes several critical components:

Linear Guide Rail: Provides the track for movement and supports the load.

Bearing Block (Carriage): Houses the rolling elements and moves along the rail.

Steel Balls: Facilitate rolling motion with minimal friction.

Ball Retainer: Maintains ball spacing and circulation.

Seals and End Caps: Prevent dust and debris ingress.

Lubrication Port: Allows grease or oil to be applied for longer service intervals.

These elements combine to form a robust, long-lasting linear motion system capable of operating in demanding environments.

How Ball Bearing Linear Mechanisms Work

The principle behind the ball bearing linear mechanism lies in the transformation of rolling motion into linear movement. As the block slides along the guide rail, the internal steel balls circulate continuously within defined paths. This design ensures load stability, high-speed performance, and reduced friction compared to sliding alternatives.

By minimizing contact friction, ball bearing linear systems achieve superior energy efficiency, lower operational noise, and increased machine accuracy.

Types of Ball Bearing Linear Systems

Ball bearing linear systems vary by design, application, and capacity. The major types include:

Miniature Linear Guides: Ideal for compact devices like medical equipment.

Standard Linear Guides: Suited for general-purpose industrial machinery.

Heavy-Duty Linear Guides: Designed for large loads and harsh conditions.

Flanged Linear Guides: Easier mounting options with stable structure.

Stainless Steel Linear Guides: Perfect for humid, chemical, or cleanroom environments.

YH Linear provides all these types, ensuring compatibility with global machine standards and offering customization options.

Ball Bearing Linear vs Roller Bearing Linear

| Feature | Ball Bearing Linear | Roller Bearing Linear |

|---|---|---|

| Rolling Element | Spherical balls | Cylindrical rollers |

| Load Capacity | Moderate to high | Very high |

| Friction | Extremely low | Slightly higher |

| Speed | Higher | Moderate |

| Precision | Excellent | Excellent |

| Best Use | CNC, 3D printing, robotics | Heavy-duty machinery |

Ball-bearing linear systems offer superior speed and smoothness, while roller-bearing systems excel in rigidity and load handling.

Key Benefits of Ball Bearing Linear Systems

Smooth Motion: Virtually frictionless rolling motion.

High Precision: Accurate linear movement for advanced equipment.

Compact Design: Space-efficient yet powerful.

Low Maintenance: Long lubrication intervals.

Quiet Operation: Ideal for noise-sensitive environments.

Longevity: Extended lifespan even under continuous load.

For engineers, these systems translate to reduced downtime, higher output quality, and overall cost efficiency.

Applications of Ball Bearing Linear Systems

Linear ball bearing systems play a pivotal role in diverse industries:

CNC and Milling Machines

Industrial Robots

3D Printers and Scanners

Semiconductor Manufacturing

Medical and Laboratory Equipment

Automated Packaging Systems

Each application benefits from the system’s combination of precision, reliability, and motion smoothness.

YH Linear Ball Bearing Linear Solutions

YH Linear Motion Systems (https://yhlinear.com/) manufactures a full range of ball bearing linear guides and motion components engineered for top-tier performance. With years of manufacturing expertise and a focus on innovation, YH Linear has become a preferred supplier for global industries seeking dependable linear motion systems.

Their products comply with international standards such as ISO, JIS, and DIN, ensuring compatibility and interchangeability with major global brands.

Why Choose YH Linear for Ball Bearing Linear Systems

Precision Manufacturing: CNC-ground rails and blocks ensure unmatched accuracy.

Material Excellence: High-quality steel resists wear and corrosion.

Competitive Pricing: Direct factory sales at global standards.

Customization Options: OEM/ODM available for all sectors.

Global Reach: Exporting to Europe, North America, and Asia.

YH Linear’s products stand out for their consistency, performance, and customer-oriented support.

Lubrication and Maintenance Guidelines

To keep your ball bearing linear system running at peak performance:

Apply recommended grease or oil every few hundred operational hours.

Clean the rail and carriage regularly to prevent particle buildup.

Inspect for alignment and preload to maintain smooth motion.

Replace seals if they show signs of wear or contamination.

Proper care ensures operational reliability and extends system life.

Frequently Asked Questions

What is a ball bearing linear system used for?

It enables smooth, precise linear motion in machines like CNCs, robots, and 3D printers.

How long does a YH Linear bearing system last?

With regular maintenance, it can last millions of cycles with consistent performance.

What makes YH Linear products reliable?

Precision manufacturing, strict quality control, and durable materials ensure long service life.

Can ball bearing linear systems handle heavy loads?

Yes. YH Linear’s heavy-duty series can support substantial industrial loads.

Do I need to lubricate my linear bearings often?

Periodic lubrication maintains optimal smoothness and prevents early wear.

Where can I purchase YH Linear products?

You can visit https://yhlinear.com/ for direct inquiries and product catalogs.

Conclusion

The ball bearing linear system is a vital innovation in modern engineering, ensuring smooth, precise, and energy-efficient motion across industries. Its low-friction operation and long lifespan make it an essential component for advanced machinery.

By choosing YH Linear Motion Systems, you invest in reliability, performance, and a partner dedicated to excellence in motion technology.

Visit https://yhlinear.com/ to explore YH Linear’s full range of linear bearings, rails, and motion components designed for the world’s most demanding applications.

Suggested Inbound and Outbound Links

Inbound Links (to YH Linear site):

Outbound Links: