Outline for “CNC Linear Slide”

| Section | Subtopics |

|---|---|

| Introduction | Importance of CNC linear slides in modern automation |

| What Is a CNC Linear Slide? | Structure and core function |

| How CNC Linear Slides Work | Motion mechanics and precision control |

| YH Linear’s Engineering Excellence | Manufacturing precision and material quality |

| Main Components of a CNC Linear Slide | Rails, blocks, drive mechanism, and supports |

| Types of CNC Linear Slides | Ball-type, roller-type, dovetail, and cross-roller slides |

| Advantages of Using CNC Linear Slides | High accuracy, durability, and low friction |

| Why Choose YH Linear CNC Slides | Brand innovation, global quality, and customization |

| Applications in CNC Machines | Milling, lathes, routers, and grinding equipment |

| Linear Slides in Robotics and Automation | Motion efficiency and integration with actuators |

| Design Considerations for Engineers | Load, travel, and mounting alignment |

| Installation and Setup Tips | How to achieve optimal performance |

| Maintenance and Lubrication Best Practices | Extending operational lifespan |

| Comparing CNC Linear Slides and Traditional Systems | Ball vs. dovetail slides |

| Performance Testing and Quality Assurance | YH Linear’s inspection standards |

| Common Problems and Troubleshooting | Noise, misalignment, and wear issues |

| Future of CNC Linear Slide Technology | Smart slides, sensors, and predictive maintenance |

| Customer Success Stories | How YH Linear slides improve real-world performance |

| FAQs | Common user questions |

| Conclusion | Summary and brand call to action |

| Suggested SEO Links | Internal and external SEO resources |

CNC Linear Slide

Precision machining depends on one thing above all: smooth and accurate linear motion.

The CNC linear slide — also known as a linear motion slide or guide — is the hidden champion behind the accuracy of every milling machine, router, or robotic arm.

At YH Linear (https://yhlinear.com/), we design, manufacture, and test CNC linear slides that redefine reliability, performance, and durability. Our engineering mastery ensures that every slide performs with micron-level precision, even under extreme industrial demands.

What Is a CNC Linear Slide?

A CNC linear slide is a mechanical component designed to provide controlled linear motion along a straight path. It is a crucial part of any CNC system, allowing machine tools and robotic devices to move smoothly and precisely.

Each slide typically consists of:

A linear rail — providing the guiding path.

A carriage or bearing block — holding the load and gliding along the rail.

A drive mechanism — such as a ball screw, belt, or linear motor that controls movement.

The result? Consistent, low-friction motion that enables exact positioning and repeatability.

How CNC Linear Slides Work

The working mechanism of a CNC linear slide relies on rolling contact between the rail and the carriage. Small steel balls or cylindrical rollers circulate within the bearing block, reducing friction and allowing precise motion.

When connected to a motorized actuator or CNC controller, the slide translates rotational motion into precise linear travel. This seamless interaction enables micron-level accuracy, vital for CNC machining, automation, and robotics.

YH Linear’s Engineering Excellence

At YH Linear, quality isn’t an afterthought — it’s built into every design stage.

We use CNC-ground rails, hardened bearing steel, and precision-assembled blocks to ensure the highest standard of accuracy and smoothness.

Key features include:

Ultra-fine 45° contact angle ball recirculation for rigidity.

Low-noise design with optimized circulation paths.

Preload adjustment for vibration damping.

ISO-certified production and inspection systems.

With YH Linear CNC slides, every micrometer counts.

Main Components of a CNC Linear Slide

| Component | Description |

|---|---|

| Linear Rail | Provides the fixed guiding surface for motion. |

| Carriage Block | Contains rolling elements for smooth travel. |

| Ball/Roller Bearings | Reduce friction and ensure stability. |

| Drive Mechanism | Moves the carriage via screw, belt, or actuator. |

| End Seals and Lubrication Ports | Protect from dust and maintain smoothness. |

These components are designed for high precision and minimal wear, even during heavy-duty cycles.

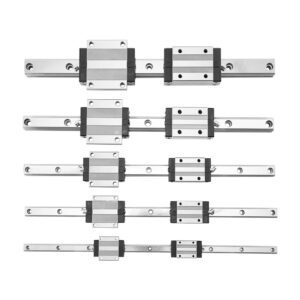

Types of CNC Linear Slides

YH Linear manufactures several types of linear slides:

Ball Bearing Slides: Offer the lowest friction for ultra-smooth motion.

Roller Bearing Slides: Provide higher load capacity for industrial applications.

Cross Roller Slides: Ideal for high precision and rigidity in compact designs.

Dovetail Slides: Traditional but robust for heavy loads.

Each type serves a different engineering demand — from lightweight automation to heavy CNC machining.

Advantages of Using CNC Linear Slides

Exceptional accuracy and repeatability

Low friction and high efficiency

Superior load-bearing capacity

Quiet and smooth motion

Compact structure and easy installation

Long lifespan with minimal maintenance

These benefits make YH Linear’s CNC slides the preferred choice for manufacturers worldwide.

Why Choose YH Linear CNC Slides

YH Linear is more than a manufacturer — we are your engineering partner.

Our custom solutions offer:

Tailor-made slide lengths and preload options.

Stainless steel or corrosion-resistant materials.

Integrated lubrication and dust-proof features.

OEM branding and co-development opportunities.

Our slides are trusted by automation companies, CNC builders, and robotics innovators globally.

Applications in CNC Machines

YH Linear CNC slides are used in:

Milling and grinding machines

CNC routers and lathes

Engraving and plasma cutting equipment

Laser and 3D printing systems

Pick-and-place automation

In every application, they deliver precision, speed, and consistency.

Linear Slides in Robotics and Automation

In robotics, a linear slide defines motion accuracy. YH Linear slides offer smooth, controlled travel for robotic arms and automated production lines.

They can be integrated with servo motors, linear actuators, or pneumatic drives, creating systems that move fast — yet stop exactly where they should.

Design Considerations for Engineers

When designing with CNC linear slides, engineers should consider:

Load and torque requirements

Travel length and speed

Mounting flatness and alignment

Environmental conditions (dust, humidity, vibration)

Maintenance accessibility

Proper selection ensures both efficiency and durability.

Installation and Setup Tips

Check mounting surface flatness before assembly.

Align parallel rails using a precision straight edge.

Tighten bolts gradually and evenly.

Use recommended lubricants before initial operation.

Test motion under no load, then increase gradually.

Following these steps ensures peak accuracy and longevity.

Maintenance and Lubrication Best Practices

Regular lubrication is key to long-term reliability.

YH Linear recommends:

Synthetic lithium-based grease for general use.

Cleanroom-compatible lubricants for medical and semiconductor industries.

Cleaning debris regularly with a lint-free cloth.

Some models come with self-lubricating systems, extending service intervals significantly.

Comparing CNC Linear Slides and Traditional Systems

| Feature | CNC Linear Slide | Traditional Dovetail Slide |

|---|---|---|

| Friction | Very Low | High |

| Accuracy | ±0.001 mm | ±0.05 mm |

| Maintenance | Minimal | Frequent |

| Load Capacity | High | Medium |

| Motion Speed | Fast | Slow |

| Durability | Long-Term | Medium-Term |

YH Linear slides clearly outperform traditional setups in every metric that matters to modern engineers.

Performance Testing and Quality Assurance

Every YH Linear slide undergoes:

Dimensional inspection with micron-level accuracy.

Noise and vibration analysis.

Load testing under simulated working conditions.

Surface roughness and hardness checks.

This ensures every product exceeds international ISO 9001 quality standards.

Future of CNC Linear Slide Technology

YH Linear is leading innovation with:

Smart sensor integration for real-time diagnostics.

Self-lubricating and dust-proof designs.

Lightweight materials for energy-efficient machinery.

Predictive maintenance powered by AI systems.

The future is about intelligent precision motion, and YH Linear is already there.

FAQs

What is a CNC linear slide used for?

It enables smooth, accurate linear movement in CNC machines, robotics, and automation systems.

How long does a YH Linear CNC slide last?

With proper care, it can perform reliably for over 50,000 hours of continuous operation.

Are YH Linear slides compatible with other systems?

Yes, they conform to international mounting standards.

Do they need frequent lubrication?

No — YH Linear offers self-lubricating designs that reduce maintenance.

Can I request custom sizes?

Yes, YH Linear offers full OEM and customized options for different industries.

Conclusion

The CNC linear slide is the backbone of precision manufacturing.

At YH Linear, we push the boundaries of motion control, creating high-performance slides that empower industries across the world.

Whether you’re designing a robotic arm, CNC router, or automation system, trust YH Linear to deliver accuracy, durability, and excellence — every single time.

Explore more at 👉 https://yhlinear.com/

Suggested SEO Links

Inbound Links (YH Linear site):

Outbound Links: