Precision engineering and industrial automation rely heavily on linear motion components, which transform rotary motion into smooth, controlled linear movement. Whether used in CNC machines, robotics, packaging systems, or laboratory instruments, these components play a vital role in ensuring accuracy, efficiency, and repeatability.

This comprehensive article delves into the world of linear motion systems—examining their types, functions, advantages, and how they integrate into modern mechanical design. With in-depth analysis, practical insights, and real-world examples, this guide serves as a must-read for engineers, designers, and industry professionals seeking to optimize performance through linear motion components.

Outline

| Section | Heading |

|---|---|

| Introduction | Understanding Linear Motion Components |

| Concept | What Are Linear Motion Components? |

| Fundamentals | Principles of Linear Motion |

| Elements | Key Components in Linear Motion Systems |

| Linear Guides | Role of Linear Guideways |

| Bearings | Linear Bearings and Their Functions |

| Shafts | Precision Shafts in Linear Motion |

| Lead Screws | Function and Types of Lead Screws |

| Ball Screws | High-Performance Ball Screw Mechanisms |

| Linear Actuators | Integration of Linear Actuators |

| Motors | Electric and Servo Motors in Motion Systems |

| Couplings | Flexible and Rigid Couplings Explained |

| Sensors | Position Feedback and Motion Control Sensors |

| Stages | Linear Motion Stages in Automation |

| Assemblies | How Linear Motion Assemblies Work |

| Applications | Industrial Applications of Linear Motion Components |

| Robotics | Linear Motion in Robotics and Automation |

| CNC Machines | Precision Motion in CNC Systems |

| Packaging | Linear Motion in High-Speed Packaging Lines |

| Medical Devices | Precision in Healthcare and Biotech Applications |

| Selection | How to Choose the Right Linear Motion Components |

| Installation | Installation and Alignment Tips |

| Maintenance | Maintenance Practices for Longevity |

| Benefits | Advantages of Linear Motion Components |

| Future Trends | Smart Linear Motion Systems in Industry 4.0 |

| FAQs | Frequently Asked Questions |

| Conclusion | The Future of Linear Motion Technology |

Understanding Linear Motion Components

Linear motion components are mechanical and electromechanical devices that enable straight-line movement within machines. They convert rotational motion—often produced by a motor—into linear displacement.

This motion is essential for a range of tasks, from guiding robotic arms and moving heavy machine tool tables to positioning delicate instruments with micron-level accuracy.

A well-designed linear motion system enhances productivity, minimizes vibration, and ensures consistent repeatability—making it indispensable in industries such as automation, manufacturing, aerospace, medical, and electronics.

What Are Linear Motion Components?

Linear motion components are the building blocks of motion systems that facilitate movement along a straight path. They include mechanical, electromechanical, and control elements such as:

Linear guideways

Bearings

Ball screws and lead screws

Shafts

Couplings

Linear actuators

Sensors and encoders

Together, these components form an integrated system that allows machines to move precisely, repeatably, and efficiently.

Principles of Linear Motion

At its core, linear motion involves the translation of rotational energy into linear displacement. This is typically achieved through mechanical conversion (as in ball screws) or direct drive systems (as in linear motors).

The performance of a linear motion system depends on:

Friction reduction

Rigidity and load capacity

Speed and acceleration

Positioning accuracy

A properly engineered linear motion system strikes a balance between these factors to achieve optimal efficiency and precision.

Key Components in Linear Motion Systems

A linear motion assembly consists of several interdependent components that collectively produce controlled movement:

Linear Guideways – Provide directional guidance and support loads.

Bearings – Minimize friction and enable smooth rolling motion.

Ball Screws/Lead Screws – Convert rotational to linear motion.

Actuators – Generate linear force and movement.

Shafts and Couplings – Transmit mechanical power accurately.

Motors and Controllers – Supply and regulate power for movement.

Sensors – Provide feedback for precision control.

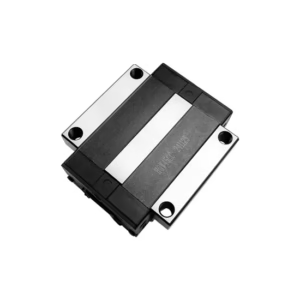

Linear Guideways

Linear guideways (also known as linear rails or slides) ensure that components move smoothly and precisely along a predefined path.

They typically consist of a hardened steel rail and a moving carriage with recirculating ball or roller bearings.

Advantages:

High precision and load capacity

Low friction and wear

Smooth, quiet motion

Long operational life

Common brands like THK, HIWIN, and NSK produce guideways tailored for high-speed, high-accuracy industrial applications.

Linear Bearings

Linear bearings provide the rolling interface that reduces friction between moving parts.

They can be classified as:

Ball bushings: Cylindrical bearings with recirculating balls, ideal for round shafts.

Plain bearings: Rely on sliding contact and are suitable for dirty or corrosive environments.

Cross-roller bearings: Use crossed rollers for ultra-high precision and rigidity.

Each bearing type offers unique benefits based on load capacity, environmental conditions, and motion speed.

Lead Screws and Ball Screws

Lead Screws

Lead screws are simple, cost-effective devices for converting rotary motion into linear motion. They are ideal for moderate precision applications such as linear stages and laboratory equipment.

Ball Screws

Ball screws use recirculating balls between the nut and the screw shaft to reduce friction dramatically.

They provide:

High efficiency (over 90%)

Excellent repeatability

Capability to handle large axial loads

These screws are commonly used in CNC machines, 3D printers, and aerospace systems.

Linear Actuators

Linear actuators convert electrical, pneumatic, or hydraulic energy into straight-line motion.

They are widely used in:

Automation systems

Conveyor systems

Adjustable machinery

Types:

Electric actuators: Use motors and screws for precise control.

Pneumatic actuators: Use air pressure for fast, short strokes.

Hydraulic actuators: Deliver strong force for heavy-duty applications.

Shafts and Couplings

Precision shafts provide the path for bearings and sliders to move along, while couplings connect shafts to motors, ensuring efficient torque transfer.

Common couplings include:

Flexible couplings – absorb misalignment.

Rigid couplings – ensure high torque transmission.

Oldham couplings – compensate for parallel misalignment.

Sensors and Feedback Systems

Modern linear motion systems integrate sensors for position, speed, and load feedback, enabling precise control through closed-loop systems.

Common sensors include:

Linear encoders

Proximity sensors

Load sensors

Limit switches

These ensure safety, accuracy, and synchronization across automation systems.

Applications of Linear Motion Components

Linear motion components are found across industries:

CNC Machining: Enables high-precision tool paths.

Robotics: Ensures accurate pick-and-place motion.

Semiconductor Manufacturing: Provides sub-micron positioning accuracy.

Packaging Lines: Enables fast, repetitive linear movements.

Medical Devices: Used in imaging systems, diagnostics, and surgical robots.

3D Printing: Ensures accurate layer deposition and alignment.

How to Choose the Right Linear Motion Components

Selecting suitable components depends on:

Load requirements (axial, radial, and moment)

Desired accuracy and repeatability

Speed and acceleration parameters

Operating environment (temperature, contamination)

Maintenance frequency and lubrication options

Consulting manufacturer data sheets or using CAD-based motion simulation tools helps ensure optimal configuration.

Maintenance and Longevity

To extend system life:

Keep rails and bearings clean.

Lubricate periodically using manufacturer-recommended grease or oil.

Check alignment and preload regularly.

Replace worn seals or damaged parts promptly.

Preventive maintenance minimizes downtime and maintains system precision.

Advantages of Linear Motion Components

High precision and stability

Low friction and wear resistance

Energy-efficient operation

Compact and modular design

Scalable for various industries

Compatible with automation and IoT systems

Future Trends in Linear Motion Systems

As industries embrace Industry 4.0, linear motion technology is evolving toward:

Smart components with built-in sensors.

Predictive maintenance through real-time data analytics.

Integrated mechatronic designs combining mechanics, electronics, and AI.

Environmentally friendly materials for sustainable automation.

These advancements promise more intelligent, reliable, and energy-efficient motion systems in the future.

Frequently Asked Questions

What are the main components of a linear motion system?

They include guideways, bearings, screws, actuators, motors, couplings, and sensors.

How is linear motion different from rotary motion?

Linear motion moves along a straight path, while rotary motion rotates around an axis.

Which industries use linear motion components most?

Automation, CNC machining, packaging, medical devices, and robotics industries.

How do you maintain linear bearings?

Clean and lubricate them regularly, keeping contaminants out of the system.

Are linear actuators better than hydraulic ones?

Electric actuators provide better control and cleanliness, while hydraulic actuators offer higher force output.

Can linear guideways handle heavy loads?

Yes, especially roller-type guideways designed for industrial-grade applications.

Conclusion

Linear motion components are at the heart of precision engineering, enabling machines to move with accuracy, reliability, and consistency. From guideways and bearings to actuators and sensors, every component plays a critical role in shaping modern automation and robotics.

As industries advance toward smarter, more connected systems, linear motion technology will continue evolving—enhancing productivity, sustainability, and design flexibility in every field of engineering.

Suggested Inbound Links:

Suggested Outbound Links: