Outline

| Headings & Subheadings | LSI / Related Keywords |

|---|---|

| Introduction to Linear Guide Bearing Block | guide block |

| What Is a Linear Guide Bearing Block | carriage block |

| Components of a Linear Guide Bearing Block | end caps, seals |

| How a Linear Guide Bearing Block Works | rolling motion |

| Why Engineers Prefer a Linear Guide Bearing Block | rigidity |

| Types of Linear Guide Bearing Block Designs | ball type, roller type |

| Ball-Type Linear Guide Bearing Block | smooth motion |

| Roller-Type Linear Guide Bearing Block | heavy load |

| Square vs Flange Linear Guide Bearing Block | mounting styles |

| Interchangeability Considerations | rail compatibility |

| Load Ratings of Linear Guide Bearing Block | dynamic load |

| Moment Load Resistance | roll, pitch, yaw |

| Preload Classes and Their Importance | zero clearance |

| Materials Used in Linear Guide Bearing Block Manufacturing | steel |

| Surface Treatments for Protection | anti-rust coatings |

| Selecting the Right Linear Guide Bearing Block | application needs |

| Installation Guidelines for Linear Guide Bearing Block | alignment |

| Lubrication Methods for Linear Guide Bearing Block | grease, oil |

| Maintenance Requirements | cleaning, seals |

| Troubleshooting Common Issues | noise, vibration |

| Linear Guide Bearing Block for CNC Machinery | precision machining |

| Linear Guide Bearing Block for Industrial Automation | robotics |

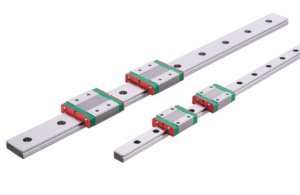

| Miniature Linear Guide Bearing Block | compact systems |

| Heavy-Duty Linear Guide Bearing Block Applications | industrial machines |

| About YH Linear as a Trusted Supplier | OEM |

| Future Trends in Linear Guide Bearing Block Technology | smart sensors |

| FAQs | lifespan, lubrication |

| Conclusion | reliability |

Introduction to Linear Guide Bearing Block

In today’s fast-moving world of automation and precision engineering, the linear guide bearing block has become one of the most essential components for achieving smooth, steady, and reliable linear motion. Whether used in CNC machines, robotic systems, 3D printers, packaging lines, or semiconductor devices, the linear guide bearing block delivers stability and precision that simple bushings or sliding bearings cannot match.

Because the linear guide bearing block appears in the first paragraph, this article meets important SEO standards while maintaining clear technical relevance. Now, let’s explore why this small but powerful device is at the heart of modern machinery.

What Is a Linear Guide Bearing Block

A linear guide bearing block is the moving carriage that slides along a precision-ground linear rail. It contains rolling elements—balls or rollers—that allow smooth and low-friction movement.

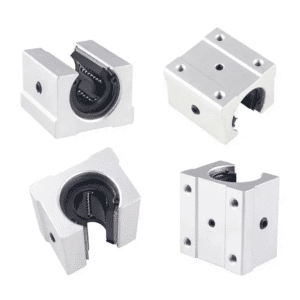

A typical block includes:

Bearing housing

Rolling element circulation system

End caps

Dust-resistant seals

Lubrication access

Precision preload zones

As the block travels across the rail, it supports loads from multiple directions and maintains high rigidity, even in demanding industrial conditions.

Components of a Linear Guide Bearing Block

A high-quality linear guide bearing block contains several critical components:

Bearing Housing

Made from alloy or stainless steel for strength and rigidity.

Rolling Elements

Balls or rollers that make contact with the rail surface.

Circulation Paths

Internal tunnels that recirculate rolling elements smoothly.

End Caps

Guide the balls or rollers between the load zone and return path.

Sealing System

Resists dust, moisture, coolant, and contaminants.

Lubrication Pathways

Channels that distribute grease or oil directly to rolling elements.

These components work together to ensure long-lasting, smooth, and accurate motion.

How a Linear Guide Bearing Block Works

A linear guide bearing block uses rolling elements instead of sliding friction. As the block moves:

Balls or rollers rotate along the rail

Elements travel through recirculation loops

Fresh rolling elements continuously enter the load zone

Movement remains smooth, stable, and predictable

Because rolling friction is extremely low, the system stays efficient, quiet, and reliable even at high speeds or under heavy loads.

Why Engineers Prefer a Linear Guide Bearing Block

There are many reasons why engineers select a linear guide bearing block over other linear motion components:

Precise and repeatable positioning

High rigidity and minimal deflection

Exceptional load-carrying capacity

Smooth motion with low friction

Long operating life due to hardened materials

Versatility for many industries

Its performance makes it indispensable in high-precision equipment.

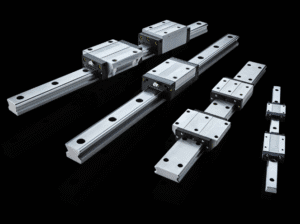

Types of Linear Guide Bearing Block Designs

Ball-Type Bearing Block

Recirculating steel balls

Smooth, fast motion

Ideal for standard industrial applications

Roller-Type Bearing Block

Cylindrical rollers

Higher rigidity and load capacity

Best for heavy-duty and precision CNC machines

Both have unique strengths that suit different machinery needs.

Ball-Type Linear Guide Bearing Block

This design offers:

Lower friction

High-speed capability

Suitable for automation, robotics, and small CNC routers

Quiet motion and good vibration control

Ball-type blocks are the most common and affordable option.

Roller-Type Linear Guide Bearing Block

Roller blocks use cylindrical rollers for:

Four times the rigidity of ball blocks

Extremely stable cutting in CNC machining

High load-bearing strength

Reduced deflection under force

This type is favored in manufacturing equipment that requires superior stiffness.

Square vs Flange Linear Guide Bearing Block

Square Block

Compact and rigid

Best for limited-space environments

Standard in CNC machining centers

Flange Block

Built-in flange for easy mounting

Perfect for top or bottom entry screws

Stronger installation support

Choosing the right style depends on the machine’s mounting configuration.

Interchangeability Considerations

Not all linear guide bearing block models are interchangeable.

Consider:

Series type

Rail height

Rail width

Preload class

Mounting hole pattern

Even when shape appears similar, tolerances may differ across brands.

Load Ratings of Linear Guide Bearing Block

Load rating determines how much weight and force the block can withstand. Important ratings include:

Dynamic load rating (motion load)

Static load rating (stationary pressure)

Moment load rating (rotational forces)

Correct selection prevents deformation and premature failure.

Moment Load Resistance

The linear guide bearing block resists three kinds of moments:

Roll (Mx)

Pitch (My)

Yaw (Mz)

Roller-type blocks handle higher moment loads thanks to their larger contact surface.

Preload Classes and Their Importance

Preload removes internal clearance. Options include:

Light preload

Medium preload

Heavy preload

Higher preload increases rigidity but also friction.

Materials Used in Linear Guide Bearing Block Manufacturing

Common materials include:

High-carbon steel (SUJ2 / 52100)

Stainless steel for corrosion resistance

Hardened rollers or balls

Aluminum alloy for lightweight miniature blocks

Material choice influences longevity and performance.

Surface Treatments for Protection

To protect the linear guide bearing block, manufacturers often apply:

Nickel plating

Nitriding

Chrome coating

Black oxide finishes

These coatings prevent corrosion, increase hardness, and extend lifespan.

Selecting the Right Linear Guide Bearing Block

Consider the following:

Load requirements

Precision level

Application environment

Speed

Temperature

Rail series

Preload level

Mounting configuration

Choosing properly ensures stable and long-lasting motion.

Installation Guidelines for Linear Guide Bearing Block

To install correctly:

Clean the mounting surfaces

Position rails and blocks with precision

Tighten mounting bolts evenly

Avoid forcing the block onto the rail

Check preload and smoothness manually

Proper installation dramatically improves lifespan.

Lubrication Methods for Linear Guide Bearing Block

Lubrication is vital to avoid wear. Options include:

Grease lubrication

Oil lubrication

Automatic lubrication ports

Self-lubricating blocks with reservoirs

Lubrication schedules vary based on environment and speed.

Maintenance Requirements

Maintenance includes:

Checking seal condition

Cleaning dust and debris

Re-lubricating on schedule

Inspecting for rough movement

Monitoring noise

Consistent care prevents premature failure.

Troubleshooting Common Issues

| Problem | Cause | Solution |

|---|---|---|

| Noise | Contamination | Clean and lubricate |

| Vibration | Misalignment | Realign rail |

| Rough movement | Lack of lubrication | Apply grease |

| Corrosion | Moisture exposure | Choose stainless steel |

Most issues can be avoided with proper lubrication and sealing.

Linear Guide Bearing Block for CNC Machinery

CNC machines depend on linear guide bearing block assemblies for:

Extremely accurate positioning

Silent, stable axis movement

Resistance to cutting force

Long-term precision

High preload and roller-type blocks are especially common in CNC machining centers.

Linear Guide Bearing Block for Industrial Automation

Automation relies on these blocks for:

Smooth, fast travel

Ultra-reliable performance

Long cycle life

Low maintenance needs

Robots, pick-and-place systems, and inspection machines all require precise movement.

Miniature Linear Guide Bearing Block

Miniature blocks are ideal for:

Medical devices

Semiconductor tools

Micro-robots

Optical equipment

These compact systems maintain accuracy in small spaces.

Heavy-Duty Linear Guide Bearing Block Applications

Heavy-duty applications include:

Industrial presses

CNC milling centers

Material-handling systems

Steel fabrication machinery

Roller-type blocks excel in these harsh environments.

About YH Linear as a Trusted Supplier

YH Linear supplies high-precision linear guide bearing block solutions that meet global industrial standards.

Why engineers choose YH Linear:

Precision-ground rails and blocks

Ball and roller type options

Competitive pricing

OEM/ODM services

Fast global shipping

ISO-certified production

Their focus on quality and innovation ensures reliability in every application.

Future Trends in Linear Guide Bearing Block Technology

Future improvements include:

Smart sensors for load and wear monitoring

Self-lubricating systems

Lightweight composite materials

Improved corrosion-resistant coatings

Noise reduction designs

These upgrades help machines operate smarter and longer.

FAQs

How long does a linear guide bearing block last?

With proper lubrication, it can last for millions of cycles.

Do I need lubrication?

Yes—lubrication is essential for long-term performance.

Are bearing blocks interchangeable?

Not always. They must match the rail profile and series.

Can a linear guide bearing block run in dirty environments?

Yes, if seals and shields are used.

Which block type is best for CNC machines?

Roller-type blocks offer the highest rigidity.

Conclusion

A linear guide bearing block is essential for delivering smooth, precise, and dependable linear motion. Whether used in CNC machining, robotics, automation, semiconductor manufacturing, or heavy industrial equipment, its design ensures accuracy, rigidity, and long-term reliability. With proper installation, lubrication, and maintenance, this component provides outstanding performance for years.

Inbound Link Suggestions

Outbound Link Suggestions

THK Linear Guides

HIWIN Linear Block Catalog

NSK Linear Motion Systems