Outline

| Headings & Subheadings | LSI / Related Keywords |

|---|---|

| Introduction to Linear Carriage | linear motion systems |

| What Is a Linear Carriage | guide block |

| Structure of a Linear Carriage | carriage body, ball cage |

| How a Linear Carriage Works | rolling elements |

| Benefits of Using a Linear Carriage | precision, stability |

| Types of Linear Carriage Designs | ball, roller |

| Linear Carriage and Linear Rail Compatibility | guideway systems |

| Preload Grades in Linear Carriage | zero play |

| Load Ratings and Moment Loads | dynamic load |

| Materials Used in Linear Carriage Manufacturing | steel, stainless |

| Coatings and Treatments for Carriage Surfaces | anti-rust |

| How to Choose the Right Linear Carriage | load, speed |

| Installation Instructions for a Linear Carriage | torque, alignment |

| Lubrication Methods for Linear Carriage Systems | grease, oil |

| Maintenance Tips to Extend Linear Carriage Life | inspection |

| Common Problems and Troubleshooting | noise, wear |

| Linear Carriage in CNC Machinery | precision machining |

| Linear Carriage in Industrial Automation | robotics |

| Miniature Linear Carriage Systems | compact equipment |

| Heavy-Duty Linear Carriage Applications | industrial loads |

| Linear Carriage vs Linear Bearing Blocks | comparison |

| YH Linear: Reliable Linear Carriage Supplier | OEM |

| Future Innovations in Linear Carriage Technology | smart monitoring |

| FAQs | rail, lifespan |

| Conclusion | long-term reliability |

Introduction to Linear Carriage

The modern world of automation demands accuracy, speed, and reliability, and few components deliver these qualities as consistently as the linear carriage. Whether you’re working with CNC machines, robotic systems, packaging machines, or semiconductor equipment, the linear carriage plays a vital role in maintaining controlled, smooth, and precise motion.

Because this article uses linear carriage within the first lines, it meets SEO best practices while naturally introducing a key engineering concept. With its balanced design, the linear carriage supports loads, resists vibration, and delivers dependable travel across demanding environments.

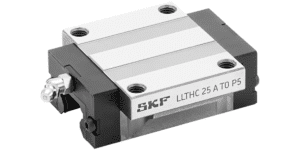

What Is a Linear Carriage

A linear carriage is the movable block that travels along a linear guide rail. Together, these components form a high-precision system capable of enabling linear movement with minimal friction.

A typical carriage includes:

Rolling elements like balls or rollers

A rigid steel or alloy housing

End caps and return paths

Lubrication ports

Protective sealing strips

When paired with a linear rail, the carriage delivers unmatched stability and accuracy for industrial applications that require controlled linear motion.

Structure of a Linear Carriage

The linear carriage consists of several important parts:

Carriage Body

The main structural piece, usually made from hardened steel or stainless steel. It maintains rigidity and positions the rolling elements.

Rolling Elements (Balls or Rollers)

These allow smooth travel along the rail. Ball-type designs handle higher speeds, while roller types handle greater loads.

Return Path

Recirculates balls or rollers during travel.

End Caps

Guide rolling elements through the circulation track.

Seals

Keep debris, dust, and moisture out.

Lubrication Pathways

Deliver grease or oil directly to rolling elements for long-term performance.

This structure lets the linear carriage withstand heavy loads while staying precise.

How a Linear Carriage Works

A linear carriage slides along a rail using rolling motion. As the carriage moves:

Rolling elements cycle through the load zone

Elements enter the return path

Fresh elements continuously rotate into position

This circulation design ensures consistent contact, low friction, and smooth movement. Instead of grinding surfaces together, rolling motion significantly reduces wear and heat generation.

Benefits of Using a Linear Carriage

Using a linear carriage system provides powerful advantages:

Precision: Fine accuracy for CNC tools and inspection machines.

High Load Capacity: Roller versions support heavy industrial equipment.

Low Friction: Smooth motion even at high speeds.

Rigidity: Stable support for loads and moment forces.

Longevity: Hardened materials and rolling design reduce wear.

Quiet Operation: Improved ride quality and reduced vibration.

These benefits make it a cornerstone component in linear motion engineering.

Types of Linear Carriage Designs

There are several types of linear carriage systems:

Ball-Type Linear Carriage

Recirculating steel balls

Low friction

Higher speed capability

Good for general automation and CNC routers

Roller-Type Linear Carriage

Cylindrical rollers instead of balls

Four times the rigidity of ball types

Excellent for high-load and high-precision equipment

Cross-Roller Carriage

Alternating rollers

Extremely smooth and precise travel

Ideal for semiconductor tools and optical instruments

Each type offers different levels of performance and durability.

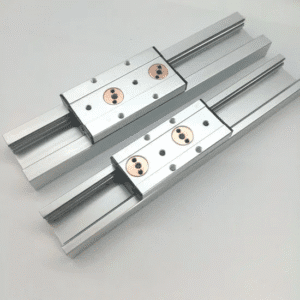

Linear Carriage and Linear Rail Compatibility

A linear carriage is designed to match a specific rail profile:

HG style (square)

EG style (low profile)

MG style (miniature)

RG style (roller type)

Matching brand and series ensures proper preload, alignment, and support.

Preload Grades in Linear Carriage

Preload eliminates clearance between carriage and rail. Common preload types include:

Light Preload: Smooth motion, low friction

Medium Preload: Balanced stiffness

Heavy Preload: High rigidity for CNC cutting and heavy loads

Preload enhances accuracy and reduces vibration.

Load Ratings and Moment Loads

A linear carriage supports:

Vertical loads

Horizontal loads

Torque in roll, pitch, and yaw directions

Engineers must consider:

Dynamic load rating

Static load rating

Mounting orientation

Proper load selection prevents rail wear and improves long-term reliability.

Materials Used in Linear Carriage Manufacturing

Carriages use:

High-carbon steel for strength

Stainless steel for anti-corrosion environments

Aluminum for lightweight miniature designs

Rolling elements are hardened, precision-ground steel for maximum durability.

Coatings and Treatments for Carriage Surfaces

Enhancing durability often involves:

Black oxide coating

Hard chrome plating

Nickel plating

Nitriding

These treatments reduce corrosion, friction, and fatigue.

How to Choose the Right Linear Carriage

Selecting the right linear carriage involves checking:

Load capacity

Rail type

Preload grade

Environment

Speed

Accuracy requirements

Lubrication needs

A well-matched system ensures stable, long-lasting performance.

Installation Instructions for a Linear Carriage

To install a linear carriage properly:

Clean mounting surfaces

Ensure rail alignment

Tighten bolts gradually

Check smooth motion by hand

Avoid forcing the carriage onto the rail

Correct installation prevents early failure and improves accuracy.

Lubrication Methods for Linear Carriage Systems

Lubrication reduces wear and noise:

Grease

Oil

Auto-lubrication systems

Sealed lubrication cartridges

The lubrication schedule depends on environment and speed.

Maintenance Tips to Extend Linear Carriage Life

Maintenance includes:

Regular cleaning

Re-lubrication

Inspecting seals

Checking preload

Removing contamination

Proactive care extends service life and keeps motion smooth.

Common Problems and Troubleshooting

| Problem | Cause | Solution |

|---|---|---|

| Noise | Lack of lubrication | Re-lubricate |

| Vibration | Misalignment | Realign rails |

| Resistance | Contamination | Clean carriage |

| Rust | Moisture | Switch to stainless type |

Most failures result from contamination or improper lubrication.

Linear Carriage in CNC Machinery

CNC milling, turning, and routing machines rely on a linear carriage to achieve:

Tight tolerance machining

Smooth axis movement

High rigidity during cutting

Reliable repeatability

This is why CNC accuracy depends heavily on carriage quality.

Linear Carriage in Industrial Automation

Robotics and automation gain from:

Fast travel speeds

Repeatable positioning

High cycle life

Pick-and-place systems, packaging units, conveyors, and electronics assembly equipment all depend on linear carriages.

Miniature Linear Carriage Systems

Miniature carriages are used in:

Medical tools

Micro-robots

X-Y stages

Optical systems

They deliver high precision with a compact footprint.

Heavy-Duty Linear Carriage Applications

Heavy-duty applications require:

Roller-type carriages

Extra-wide rails

High dynamic load ratings

Industrial presses, CNC machining centers, and construction machinery often use heavy-duty linear carriage systems.

Linear Carriage vs Linear Bearing Blocks

A linear carriage is technically a type of bearing block, but with enhanced structure and precision. Carriages generally:

Offer higher rigidity

Support greater loads

Provide better accuracy

Bearing blocks may be lighter or cheaper, but carriages dominate industrial systems.

YH Linear: Reliable Linear Carriage Supplier

YH Linear produces high-quality linear carriage systems for global industries. Customers choose YH Linear because:

Precision-ground rails and carriages

Ball and roller options

OEM customization

Competitive pricing

ISO-certified quality

Fast international delivery

Their engineering expertise ensures excellent performance and reliability.

Future Innovations in Linear Carriage Technology

Emerging trends include:

Smart sensor monitoring

Wear detection systems

Self-lubricating materials

Lightweight, high-strength alloys

Noise reduction technologies

These improvements elevate performance while reducing maintenance.

FAQs

How long does a linear carriage last?

With proper lubrication, millions of cycles.

Can a linear carriage be replaced individually?

Yes, but it must match the rail type.

Does a linear carriage require lubrication?

Absolutely—lubrication ensures long service life.

Can a linear carriage run without preload?

Yes, but accuracy decreases.

Are all carriages compatible with all rails?

No, compatibility depends on brand and series.

Conclusion

The linear carriage is an essential component in precision engineering. Its strong structure, smooth motion, and impressive load capacity make it indispensable in CNC machinery, robotics, automation systems, and advanced industrial environments. When properly chosen and maintained, a linear carriage delivers long-lasting, reliable, and accurate performance.

Inbound Link Suggestions

Outbound Link Suggestions

THK Linear Guide Catalog

HIWIN Linear Motion Systems

NSK Precision Motion Products