Outline

| Headings & Subheadings | LSI / Related Keywords |

|---|---|

| Introduction to Linear Bearing and Rail | linear motion components |

| What Is a Linear Bearing and Rail System | linear guideway |

| Structure of a Linear Bearing and Rail | bearing block, guide rail |

| How a Linear Bearing and Rail Works | rolling motion, friction reduction |

| Benefits of Linear Bearing and Rail Systems | precision, rigidity |

| Types of Linear Bearings Used on Rails | ball, roller, cross-roller |

| Types of Rails in Linear Motion | profile rails, round rails |

| Linear Bearing and Rail vs Shaft Support Systems | comparison |

| Materials Used in Linear Bearing and Rail Systems | steel, stainless steel |

| Surface Treatments and Coatings | corrosion protection |

| Selecting the Right Linear Bearing and Rail | load, speed, accuracy |

| Installation Guidelines | alignment, torque |

| Lubrication Requirements | grease, oil, automatic lubrication |

| Maintenance Practices | cleaning, inspection |

| Common Problems and Troubleshooting Tips | noise, wear |

| Environmental Considerations | dust, moisture |

| Linear Bearing and Rail for CNC Machines | precision machining |

| Linear Bearing and Rail for Automation | industrial robotics |

| Heavy-Duty Linear Rail Systems | industrial loads |

| Miniature Linear Bearing and Rail | compact devices |

| YH Linear: Reliable Linear Bearing and Rail Supplier | OEM, customization |

| Innovations in Linear Rail Technology | smart sensors |

| FAQs | lubrication, lifespan |

| Conclusion | reliability and performance |

Introduction to Linear Bearing and Rail

In modern manufacturing and automation, the linear bearing and rail system plays a crucial role in delivering accurate, repeatable, and smooth motion. Whether it is in CNC machines, robotic platforms, or advanced packaging systems, this dynamic duo ensures precise linear travel and superior load capacity.

Because the linear bearing and rail combination appears early in this article, it supports both SEO goals and technical clarity. Now, let’s explore how this critical mechanical system powers modern engineering.

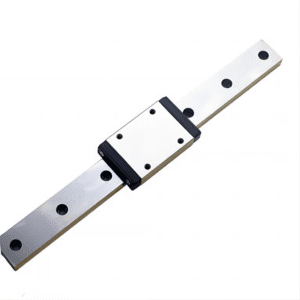

What Is a Linear Bearing and Rail System

A linear bearing and rail system is a mechanical assembly designed to provide controlled, low-friction linear movement along a straight path.

It typically includes:

A hardened guide rail

A bearing block or carriage

Rolling elements such as balls or cylindrical rollers

These components work together to reduce friction, improve rigidity, and maintain accuracy during linear travel. Unlike simple bushings, the rail provides a stable track that resists twisting, bending, and vibration.

Structure of a Linear Bearing and Rail

A complete linear bearing and rail assembly contains:

Guide Rail

Typically made of high-carbon or stainless steel

Ground with extreme precision

Supports loads in multiple directions

Bearing Block (Carriage)

Houses rolling elements

Moves smoothly along the rail

Includes seals, lubrication ports, and preload adjustments

Rolling Elements

Ball bearings

Cylindrical rollers

Crossed rollers

Each structure contributes to smooth motion, high rigidity, and long operating life.

How a Linear Bearing and Rail Works

The linear bearing and rail system operates using rolling motion instead of sliding. Rolling elements between the bearing block and the rail rotate as the block moves.

This results in:

Very low friction

Smooth, stable operation

Long-lasting accuracy

Reduced wear and energy consumption

Because the rail guides the bearing block so precisely, the system maintains its path even under dynamic loads.

Benefits of Linear Bearing and Rail Systems

Choosing a linear bearing and rail system offers many advantages:

High Accuracy: Ensures precise positioning for machining and automation.

Superior Rigidity: Withstands heavy loads without bending.

Low Friction: Reduces energy consumption and heat generation.

High Load Capacity: Handles large dynamic and static forces.

Long Lifespan: Hardened surfaces and rolling motion maximize durability.

Smooth Travel: Eliminates vibration, which improves product quality.

These qualities make them an essential part of modern industrial machinery.

Types of Linear Bearings Used on Rails

Ball-Type Linear Bearings

Contains recirculating steel balls

Ideal for fast motion

Low friction and good precision

Roller-Type Linear Bearings

Uses cylindrical rollers

Higher rigidity

Supports heavy-duty applications

Cross-Roller Bearings

Alternating rollers arranged perpendicularly

Extremely smooth and precise motion

Perfect for measuring systems or robotic arms

Each type influences the performance and load capacity.

Types of Rails in Linear Motion

Profile Linear Rails

Rectangular, ground profiles

Common in CNC and industrial automation

High load capacity and rigidity

Round Shaft Rails

Circular shafts with mounted bearings

Cheaper and easier to install

Lower rigidity than profile rails

Profile rails are preferred for precision tasks, while round rails suit lighter applications.

Linear Bearing and Rail vs Shaft Support Systems

| Feature | Linear Bearing & Rail | Linear Shaft System |

|---|---|---|

| Rigidity | Very high | Moderate |

| Load Capacity | High | Low–medium |

| Accuracy | Excellent | Average |

| Cost | Higher | Lower |

| Installation | More precise | Easier |

The linear bearing and rail system is the ideal option when accuracy and rigidity are essential.

Materials Used in Linear Bearing and Rail Systems

High-Carbon Bearing Steel (SUJ2 / 52100): Standard choice for precision rails

Stainless Steel: For corrosion-resistant environments

Alloy Steel: Enhanced strength and wear resistance

Aluminum Carriages: Lightweight solutions for small loads

Material choice affects performance, durability, and cost.

Surface Treatments and Coatings

Surface treatments improve durability:

Chrome Plating: Wear resistance

Black Oxide: Mild corrosion protection

Nickel Plating: Strong anti-corrosion properties

Nitriding: Extreme hardness

These coatings keep rails and bearings running smoothly even in harsh conditions.

Selecting the Right Linear Bearing and Rail

When selecting a linear bearing and rail, consider:

Load capacity (static and dynamic)

Moment loads

Precision level

Travel speed

Rail mounting configuration

Environmental exposure

Lubrication requirements

Matching these criteria ensures reliable performance and long service life.

Installation Guidelines

Proper installation is essential:

Clean all mounting surfaces

Ensure flatness and correct parallelism

Use precise torque settings

Install rails gradually to avoid twisting

Test carriage movement manually

Good installation minimizes wear and misalignment.

Lubrication Requirements

Lubrication is essential because it:

Minimizes wear

Reduces noise

Extends bearing life

Prevents corrosion

Most linear bearing and rail systems use:

Lithium-based grease

Low-viscosity oil

Automatic lubrication ports

Lubrication schedules depend on speed, load, and environment.

Maintenance Practices

To maintain peak performance:

Clean rail surfaces regularly

Reapply grease on schedule

Inspect preload and play

Replace worn seals

Listen for unusual noise or vibration

Routine maintenance avoids costly downtime.

Common Problems and Troubleshooting Tips

| Problem | Cause | Fix |

|---|---|---|

| Noise | Contamination | Clean & re-lubricate |

| Rough Movement | Misalignment | Reinstall or adjust rail |

| Vibration | Insufficient lubrication | Apply correct grease |

| Corrosion | Moisture exposure | Use stainless steel rails |

Most problems are preventable with proper care.

Environmental Considerations

The linear bearing and rail system may encounter:

Dust

Humidity

Coolant spray

Metal chips

High heat

Sealed bearings or stainless steel rails help protect against these conditions.

Linear Bearing and Rail for CNC Machines

CNC systems rely on linear bearing and rail assemblies for:

Smooth axis movement

Vibration-free positioning

High rigidity during cutting

Long-term accuracy

CNC milling, turning, and routing machines all depend heavily on profile rails.

Linear Bearing and Rail for Automation

Automation systems need:

Repeatable motion

High-speed travel

Stable positioning

Robotic platforms, pick-and-place units, conveyors, and assembly machines all benefit from the precise movement that linear bearings and rails offer.

Heavy-Duty Linear Rail Systems

For rugged industrial environments:

Roller-type bearings

Oversized rails

Increased contact area

Higher shock resistance

These systems handle extreme loads found in machining centers, presses, and material-handling systems.

Miniature Linear Bearing and Rail

These compact systems are ideal for:

Medical instruments

Micro-robots

Semiconductor equipment

Optical devices

Miniature rails offer precision in tight spaces.

YH Linear: Reliable Linear Bearing and Rail Supplier

YH Linear provides a complete range of linear bearing and rail solutions crafted for accuracy, durability, and consistency.

Why engineers choose YH Linear:

High-precision ground rails

Ball and roller bearing options

OEM & ODM services

Competitive pricing

Global shipping

ISO-certified manufacturing

YH Linear delivers dependable motion solutions for industries around the world.

Innovations in Linear Rail Technology

Recent advancements include:

Self-lubricating bearing blocks

Noise-reduction designs

Smart load monitoring

Lightweight aluminum housings

Enhanced corrosion-resistant coatings

These innovations improve performance and reduce maintenance demands.

FAQs

How long do linear bearings and rails last?

With proper lubrication, they can run for millions of cycles.

Do linear rails require lubrication?

Yes, lubrication is essential for smooth operation and long life.

Are linear rails interchangeable between brands?

Some brands follow similar dimensions, but compatibility must be verified.

Can linear rails handle high-speed applications?

Ball-type bearings are suitable for high-speed movement.

Conclusion

The linear bearing and rail system is the backbone of modern precision motion. Its rigid structure, smooth operation, and exceptional load capacity make it the preferred choice for CNC machinery, industrial automation, robotics, medical devices, and more. With proper installation and maintenance, these systems support long-term reliability and outstanding performance across countless industries.

Inbound Link Suggestions

Outbound Link Suggestions

THK Linear Motion Systems

HIWIN Linear Guides

NSK Linear Bearings