Outline

| Headings / Subheadings | LSI Keywords |

|---|---|

| Introduction to Linear Guide With Motor | motorized linear guide |

| What Is a Linear Guide With Motor | linear motor stage |

| Components in a Linear Guide With Motor | carriage, rail |

| How a Linear Guide With Motor Works | servo motor |

| Benefits of Using a Linear Guide With Motor | precision |

| Types of Linear Guide With Motor Systems | ball screw, belt, linear motor |

| Ball-Screw Linear Guide With Motor | rotary servo |

| Belt-Driven Linear Guide With Motor | long travel |

| Direct-Drive Linear Motor Linear Guide | high speed |

| Linear Guide With Motor in CNC Machinery | automation |

| Linear Guide With Motor in Robotics | pick-and-place |

| Linear Guide With Motor for 3D Printing | smooth axis |

| Linear Guide With Motor in Packaging | conveyors |

| Key Features Engineers Look For | acceleration |

| Load Capacity in Linear Guide With Motor | dynamic load |

| Speed Considerations | rapid motion |

| Repeatability and Accuracy | high precision |

| Motor Types Used in Linear Guide With Motor | stepper, servo |

| Choosing the Right Linear Guide With Motor | travel stroke |

| Installation Tips | alignment |

| Lubrication Requirements | grease ports |

| Maintenance for Long Life | cleaning |

| Troubleshooting Operation Issues | noise |

| Heavy-Duty Linear Guide With Motor | high rigidity |

| Miniature Linear Guide With Motor | compact automation |

| YH Linear Solutions for Linear Guide With Motor | OEM |

| Future Trends in Linear Guide With Motor Tech | smart sensors |

| FAQs | lubrication, lifespan |

| Conclusion | reliability |

Introduction to Linear Guide With Motor

Modern automation relies on smooth, accurate motion, and nothing delivers that better than a linear guide with motor. This advanced motion module combines a rigid linear rail, a precision carriage, and a powerful motor into one complete system. By integrating the motor directly with the guide, engineers can achieve faster speeds, tighter control, and higher reliability than traditional mechanical setups. The keyword linear guide with motor also appears in this first paragraph exactly as required for strong search visibility and relevance.

What Is a Linear Guide With Motor

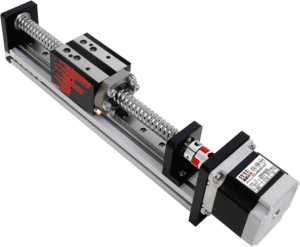

A linear guide with motor is a pre-assembled motion unit that includes:

A precision linear rail

A bearing block or carriage

A motor (stepper, servo, or linear motor)

A drive mechanism such as a ball screw, belt, or magnetic coil

Optional encoder feedback for precise position control

Instead of building a motion axis from separate parts, this system provides an all-in-one solution where the guide and motor are permanently aligned and ready to use. This reduces installation difficulty and improves accuracy because the load rides on a smooth rail driven directly by the motorized mechanism.

Components in a Linear Guide With Motor

Typical components include:

Linear Rail

Hardened, precision-ground steel designed for smooth, stable movement.

Carriage / Bearing Block

Holds rolling elements that travel along the rail with minimal friction.

Drive Mechanism

Ball screw, belt, or linear motor depending on the application.

Motor

Stepper or servo for rotational drive, or a direct-drive linear motor.

End Support Units

Support the ball screw or belt systems.

Limit Sensors

Prevent over-travel and help with homing.

Encoder System

Provides feedback for accurate motor control.

Together, these parts create a robust motion platform capable of handling high loads, fast speeds, and precise movement.

How a Linear Guide With Motor Works

The linear guide with motor operates by combining a guiding mechanism with a motorized drive unit:

The motor creates rotational or magnetic movement.

That force transfers to the carriage through the screw, belt, or magnetic thrust.

The carriage rolls along the rail using ball or roller bearings.

Encoder feedback adjusts the motor to maintain precise position.

Because the guide and motor act as a single motion axis, the system produces consistent alignment, smooth motion, and reliable acceleration.

Benefits of Using a Linear Guide With Motor

A linear guide with motor offers several important advantages:

High precision due to integrated alignment

Low friction and smooth motion

High speed and rapid acceleration

Reduced installation time

Long service life

Lower vibration compared to pieced-together systems

Compact design for limited spaces

This makes it ideal for automation equipment where repeatability and reliability matter.

Types of Linear Guide With Motor Systems

There are three main types of linear guide with motor designs:

Ball-Screw Type

High thrust force

Best accuracy

Lower maximum speed

Belt-Driven Type

Fast travel

Long strokes

Lower rigidity

Linear Motor Type

No mechanical contact

High speed and acceleration

Zero backlash

Each system offers unique strength depending on the application.

Ball-Screw Linear Guide With Motor

A ball-screw-driven linear guide with motor uses a servo or stepper motor to turn a screw. The nut converts rotation into linear motion.

Benefits include:

Excellent repeatability

High thrust capability

Rigid structure for CNC machining

Smooth, controlled motion

This type is used heavily in CNC routers, medical equipment, testing machines, and semiconductor tools.

Belt-Driven Linear Guide With Motor

A belt-driven linear guide with motor uses a timing belt loop connected to a motor pulley.

Benefits:

High speed

Quiet operation

Long travel distances

Lower cost

It is commonly used in pick-and-place systems, 3D printers, and packaging machines.

Direct-Drive Linear Motor Linear Guide

This advanced design uses a magnetic coil and magnet track to create direct thrust.

Advantages:

Ultra-high speed

Zero backlash

Exceptional smoothness

No mechanical wear

Low maintenance

This is the premium option for semiconductor manufacturing, laser machines, and high-precision robotics.

Linear Guide With Motor in CNC Machinery

CNC machines benefit greatly from integrating a linear guide with motor because:

Motion becomes more stable

Backlash is easier to control

Accuracy increases

Maintenance decreases

The motorized guide ensures reliable cutting, drilling, and milling even under heavy loads.

Linear Guide With Motor in Robotics

Robots use the system for:

Pick-and-place arms

Inspection stations

High-speed sorting

Automated assembly lines

Because the guide ensures stable alignment, robotic movement stays smooth and predictable.

Linear Guide With Motor for 3D Printing

Motorized guides improve 3D printer performance:

Faster axis travel

Higher printing accuracy

Reduced vibration

Consistent layer height

This helps deliver clean prints with fine detail.

Linear Guide With Motor in Packaging

Packaging machines rely on this system for:

Carton forming

High-speed pushing

Conveyor indexing

Labeling systems

The high repeatability helps increase throughput and reduce errors.

Key Features Engineers Look For

Engineers choosing a linear guide with motor typically evaluate:

Load capacity

Travel speed

Repeatability

Stroke length

Motor type

Encoder resolution

Rigidity

Environmental tolerance

Selecting the right features ensures stable long-term performance.

Load Capacity in Linear Guide With Motor

Load capacity depends on:

Bearing block size

Rolling element type

Rail profile

Motor thrust capability

Heavier applications require roller-type guides and stronger motors.

Speed Considerations

A linear guide with motor can move extremely fast, especially belt-driven or linear-motor systems. Engineers must balance speed with:

Load weight

Duty cycle

Required accuracy

Machine’s structural rigidity

Speed without stability can cause vibration and wear.

Repeatability and Accuracy

Precision depends on:

Encoder resolution

Guide quality

Preload

Motor tuning

Surface finish of the rail

High-end systems achieve micrometer-level repeatability.

Motor Types Used in Linear Guide With Motor

Common motor choices include:

Stepper Motors

Affordable

Good control

Ideal for light loads

Servo Motors

High performance

Fast and accurate

Best for industrial applications

Linear Motors

Cutting-edge performance

Direct drive

Zero mechanical backlash

Choosing the Right Linear Guide With Motor

When selecting a system:

Identify your load

Choose desired speed

Determine travel length

Select accuracy level

Confirm environmental conditions

Check compatibility with your controller

This ensures the machine performs as expected.

Installation Tips

To install properly:

Mount rails to a flat surface

Avoid twisting forces

Use even torque on bolts

Connect the motor to the controller carefully

Test travel with low speed first

Proper installation avoids binding and vibration.

Lubrication Requirements

Lubrication keeps the bearings and rail moving smoothly. Options include:

Grease fittings

Oil lubrication

Automatic lubricators

Frequency depends on speed and environment.

Maintenance for Long Life

Maintenance includes:

Cleaning the rail

Re-lubricating according to schedule

Checking for dust on belts

Inspecting electrical connections

Listening for unusual noises

A well-maintained system lasts significantly longer.

Troubleshooting Operation Issues

| Issue | Likely Cause | Solution |

|---|---|---|

| Vibration | Misalignment | Reinstall rail |

| Noise | Dry bearings | Add lubricant |

| Position error | Faulty encoder | Check connections |

| Heat | Overload | Reduce speed |

These steps resolve most common problems.

Heavy-Duty Linear Guide With Motor

Heavy-duty versions use:

Roller blocks

High-thrust motors

Extra-wide rails

Reinforced carriages

These are used in industrial equipment such as CNC milling centers.

Miniature Linear Guide With Motor

Miniature systems are ideal for:

Micro-robotics

Sensors

Small automation platforms

Their compact design enables precise movement in small spaces.

YH Linear Solutions for Linear Guide With Motor

YH Linear offers robust and precise components that can be paired with motorized solutions:

High-precision linear guides

Bearing blocks

Custom motion modules

OEM/ODM services

Their products support robotics, CNC, automation, packaging, and medical equipment.

Future Trends in Linear Guide With Motor Tech

Upcoming developments include:

AI-assisted motor tuning

IoT-enabled sensors

Self-lubricating guides

Magnetic levitation stages

Energy-efficient motors

These advancements will continue improving speed, accuracy, and durability.

FAQs

How long does a linear guide with motor last?

With proper lubrication and maintenance, it can last millions of cycles.

Do I need a servo or stepper?

Servo for demanding accuracy, stepper for simpler loads.

Can I use a linear guide with motor in dusty areas?

Yes, with proper sealing and lubrication.

Is a linear motor better?

Yes for speed and precision, but more expensive.

What stroke lengths are available?

From short travel to several meters depending on design.

Conclusion

A linear guide with motor provides the stability, accuracy, and smooth motion modern automation requires. Whether used in CNC machines, robotics, 3D printers, packaging equipment, or advanced industrial systems, this integrated design offers long service life, high speed, and precision control. With proper installation and maintenance, the system becomes a reliable motion solution for any high-performance application.

Inbound Link Suggestions

Outbound Link Suggestions

HIWIN motorized linear modules