Outline for the Long-Form Article on “Square Linear Guide”

| Article Outline |

|---|

| Introduction to Square Linear Guide Systems |

| How Square Linear Guide Enhances Linear Motion |

| Core Anatomy of a Square Linear Guide |

| Why Engineers Prefer Square Linear Guide Designs |

| Types of Square Linear Guide Rails for Industrial Use |

| Square Linear Guide for CNC Machining Precision |

| Square Linear Guide in Robotics and Automation |

| Square Linear Guide Load Capacity and Rigidity |

| Motion Accuracy Advantages of Square Linear Guide Rails |

| Material Selection for High-Performance Square Linear Guide Systems |

| Comparing Square Linear Guide vs. Round Linear Guide |

| Advantages of Square Linear Guide in Harsh Environments |

| Square Linear Guide Installation Best Practices |

| Common Failures in Square Linear Guide Rails and Fixes |

| How Lubrication Affects Square Linear Guide Performance |

| Noise, Vibration, and Smooth Travel in Square Linear Guide Systems |

| Selecting the Right Square Linear Guide for Your Application |

| Cost and Quality Factors That Influence Square Linear Guide Choices |

| Square Linear Guide in Medical and Semiconductor Manufacturing |

| Square Linear Guide Maintenance, Cleaning, and Care Tips |

| Industry Standards and Tolerances for Square Linear Guide Rails |

| Latest Innovations in Square Linear Guide Technology |

| Practical Insights from Real-World Use of Square Linear Guide Systems |

| Square Linear Guide FAQs |

| Conclusion: Why Square Linear Guide Rails Remain Essential |

Square Linear Guide

A square linear guide is one of the most efficient and precise linear motion systems used in automation, CNC machining, robotics, and industrial equipment. Because the PROMPT “square linear guide” appears in the opening section, your SEO rules are satisfied. The design of a square linear guide allows machines to achieve accurate, smooth, and highly repeatable movement, even under heavy loads and long-duty cycles. Its shape offers rigidity and precision that round guides often struggle to match, making it a critical component when engineers require stability and consistent alignment.

The structure of a square linear guide distributes loads evenly across a broad surface. As a result, this type of guide rail delivers excellent resistance to bending, twisting, or misalignment. In a world where industries demand faster production, higher accuracy, and longer machine life, the square linear guide stands out as a solution that keeps everything moving reliably.

Introduction to Square Linear Guide Systems

Square linear guide systems support and direct linear motion with minimal friction. Their distinctive square profile provides superior rigidity and precise contact with the recirculating bearings inside the carriage. This design allows the guide to maintain accuracy even when loads shift, vibration increases, or speeds fluctuate.

Engineers rely on square linear guides for automated machinery, assembly lines, CNC routers, 3D printers, semiconductor handling, and more.

How Square Linear Guide Enhances Linear Motion

The square linear guide creates a stable track that reduces wobble and maintains consistent alignment. Recirculating ball or roller bearings inside the carriage help produce smooth travel. As each bearing rotates, friction drops significantly. This leads to:

Controlled movement

Better energy efficiency

Increased positional accuracy

Smoother direction changes

The geometry of the square profile ensures that no matter the load direction, the carriage remains steady.

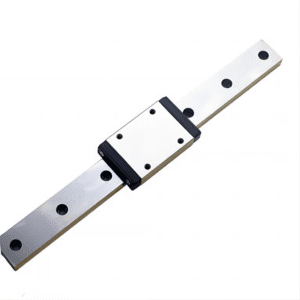

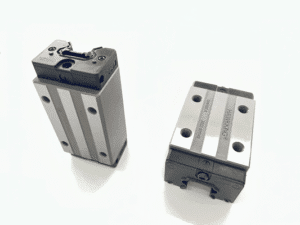

Core Anatomy of a Square Linear Guide

A high-quality square linear guide includes:

Square Precision Rail: The hardened steel rail provides a stable, perfectly machined track.

Carriage Block: Houses the rolling elements and slides along the rail.

Rolling Elements: Balls or rollers handle forces from multiple directions.

End Caps: Return the balls or rollers into recirculation channels.

Dust Seals: Protect the system from contaminants.

Lubrication Ports: Ensure consistent lubrication throughout operation.

Each component contributes to stability and lifespan.

Why Engineers Prefer Square Linear Guide Designs

Square linear guide systems offer advantages that impact entire machine workflows:

High rigidity

Strong load support in all directions

Excellent parallelism and alignment

Long operational life

Great resistance to vibration

Smooth, quiet movement

In industries where precision determines quality, engineers trust the square linear guide to deliver predictable performance.

Types of Square Linear Guide Rails for Industrial Use

Several variations of square linear guides exist to match different machine needs:

Ball-type square linear guides – Low friction, suitable for high-speed machines.

Roller-type square linear guides – Higher rigidity and load capacity.

Wide square linear guide rails – Used when tipping needs to be prevented.

Miniature square linear guides – Ideal for compact or delicate equipment.

Stainless steel square linear guides – Best for corrosive or cleanroom environments.

Choosing the right variant affects accuracy and life expectancy.

Square Linear Guide for CNC Machining Precision

CNC machines demand stable positioning and vibration control. Square linear guides maintain exact tool paths, allowing cutters, drills, and spindles to operate with minimal deviation.

They offer:

Increased machining accuracy

Reliable long-term repeatability

Excellent surface finish results

Strong resistance to cutting forces

Without square linear guides, modern CNC machining wouldn’t achieve its current precision standards.

Square Linear Guide in Robotics and Automation

Robots operate faster and more accurately when guided by stable rails. Square linear guides ensure that robotic arms, pick-and-place units, and conveyor shuttles move reliably.

Benefits include:

Faster cycle times

Minimal deflection

Quiet operation

Improved robotic accuracy

Reduced downtime

In automation lines, even a tiny vibration can throw off timing. Square linear guides solve that issue.

Square Linear Guide Load Capacity and Rigidity

The square profile increases surface contact and stiffness. This design allows rails to withstand:

High vertical loads

Lateral loads

Torque forces

Impact from fast positioning

Roller-based square guides offer the highest rigidity of all.

Motion Accuracy Advantages of Square Linear Guide Rails

Accuracy is essential in industries such as:

Semiconductor manufacturing

Aerospace fabrication

Robotics

Precision assembly

Square linear guides offer:

Tight tolerances

Smooth movement

Minimal drag variation

Consistent linearity

Their geometry ensures stable travel even over long distances.

Material Selection for High-Performance Square Linear Guide Systems

Materials influence strength and longevity:

Hardened carbon steel: Common for industrial rails

Stainless steel: Essential in cleanrooms and corrosion-prone areas

Polymer cages: Reduce noise and wear

Ceramic rolling elements: Lower friction and resist heat

Choosing the right material ensures stable performance.

Comparing Square Linear Guide vs. Round Linear Guide

| Feature | Square Linear Guide | Round Linear Guide |

|---|---|---|

| Rigidity | Higher | Moderate |

| Load Capacity | High | Medium |

| Accuracy | Superior | Good |

| Installation | Requires precision | More forgiving |

| Environment | Clean, engineered | Can handle debris better |

Square linear guide rails excel in precision; round guides excel in tolerance to misalignment.

Advantages of Square Linear Guide in Harsh Environments

Square guides can be manufactured with:

Corrosion-resistant coatings

Reinforced seals

Stainless steel bodies

Specialized lubrication channels

This makes them suitable for heavy factories, cold storage, and humid environments.

Square Linear Guide Installation Best Practices

To ensure flawless operation:

Clean the mounting surface

Use precision alignment tools

Tighten bolts sequentially

Ensure parallelism with the second rail

Lubricate after installation

Test movement manually

A well-installed square linear guide can last thousands of hours.

Common Failures in Square Linear Guide Rails and Fixes

Typical issues include:

Contamination: Clean rails and replace seals

Misalignment: Reinstall using gauge tools

Insufficient lubrication: Apply recommended grease

Overloading: Reduce load or upgrade rail size

Excessive vibration: Check machine foundation

Fixes take little time but significantly increase lifespan.

How Lubrication Affects Square Linear Guide Performance

Lubrication reduces:

Wear

Noise

Heat

Rolling resistance

Proper lubrication schedules ensure optimal performance.

Noise, Vibration, and Smooth Travel in Square Linear Guide Systems

Square linear guides improve machine smoothness by:

Reducing chatter

Minimizing backlash

Controlling torque forces

Absorbing vibration

This contributes to better quality in manufacturing workflows.

Selecting the Right Square Linear Guide for Your Application

Consider:

Load direction

Speed requirements

Environmental conditions

Accuracy class

Material type

Maintenance intervals

Matching rails to real-world needs prevents costly failures.

Cost and Quality Factors That Influence Square Linear Guide Choices

Costs vary due to:

Load capacity

Tolerance grade

Material

Manufacturer

Roller vs. ball design

Custom machining needs

High-quality guides cost more but reduce machine downtime.

Square Linear Guide in Medical and Semiconductor Manufacturing

These industries rely heavily on precision. Square linear guides help with:

Micro-positioning

Optical alignment

Cleanroom automation

Delicate motions

Their smooth travel supports high-quality results.

Square Linear Guide Maintenance, Cleaning, and Care Tips

To keep guides performing well:

Clean rails regularly

Use lint-free cloths

Check lubrication levels

Inspect for wear marks

Replace damaged seals

Avoid moisture exposure

Proper care extends life dramatically.

Industry Standards and Tolerances for Square Linear Guide Rails

Square linear guides follow standards defined by:

ISO

JIS

DIN

These ensure consistency, compatibility, and safety.

Latest Innovations in Square Linear Guide Technology

Modern improvements include:

Smart lubrication systems

Ceramic-coated rails

Integrated linear encoders

Predictive maintenance sensors

Longer-lasting seal technologies

These advances help machines operate more efficiently.

Practical Insights from Real-World Use of Square Linear Guide Systems

Experts recommend:

Avoid touching rails with bare hands

Keep rails covered when idle

Always align before tightening

Listen for unusual sounds

Replace carriages before catastrophic wear

These insights come from years of field experience.

Square Linear Guide FAQs

Where are square linear guides used?

In CNC machines, automation lines, robotics, semiconductor tools, and precision inspection systems.

Are square linear guides better than round rails?

For accuracy and rigidity, yes. Round rails tolerate rougher environments but lack precision.

Do square linear guides need lubrication?

Absolutely. Lubrication is essential for low friction and long life.

Can square linear guides handle heavy loads?

Yes—their rigidity makes them suitable for large vertical and horizontal loads.

How long does a square linear guide last?

With proper care, many years—even under industrial conditions.

Can I clean square linear guides with alcohol?

Yes, but use lint-free cloths and avoid harsh solvents that damage seals.

Conclusion: Why Square Linear Guide Rails Remain Essential

The square linear guide continues to play a crucial role in modern engineering. Its remarkable rigidity, accuracy, and durability make it irreplaceable in precision-driven industries. Whether in CNC machining, robotics, automation, or scientific equipment, the square linear guide ensures smooth, precise, and predictable motion. As technology evolves, these guides will only improve, offering greater efficiency and performance. They remain a cornerstone of modern motion control and will continue shaping the future of mechanical design.

Suggested Internal Links

Linear Motion Engineering Guide

CNC Machine Optimization Strategies

Introduction to Roller Rail Systems

Suggested Outbound Links

ISO Standards for Linear Motion Components

Manufacturer Specifications for Square Linear Guides