Outline

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Understanding the Linear Motion Rail Guide | linear rail, motion guide |

| Why the Linear Motion Rail Guide Matters in Modern Engineering | precision movement |

| Components That Make Up a Linear Motion Rail Guide | guide block, carriage |

| How a Linear Motion Rail Guide Works | low-friction travel |

| Types of Linear Motion Rail Guide Systems | ball-type, roller-type |

| Ball vs. Roller Linear Motion Rail Guide | comparison |

| Materials Used in High-Quality Linear Motion Rail Guide Manufacturing | hardened steel |

| Load Ratings in a Linear Motion Rail Guide | static load, dynamic load |

| Accuracy Classes for Linear Motion Rail Guide Systems | preload, tolerance |

| Choosing the Right Linear Motion Rail Guide for Industrial Machines | CNC selection |

| Industry Example: YH Linear Motion Rail Guide for CNC & Automation | https://yhlinear.com |

| How to Install a Linear Motion Rail Guide Properly | alignment |

| Lubrication Requirements for a Linear Motion Rail Guide | grease |

| Common Linear Motion Rail Guide Failures | wear, debris |

| How to Fix a Noisy or Sticky Linear Motion Rail Guide | troubleshooting |

| Environmental Effects on Linear Motion Rail Guide Longevity | humidity, dust |

| Linear Motion Rail Guide for CNC Routers & Milling Machines | X/Y/Z axis |

| Use of Linear Motion Rail Guide in Robotics & Automation | robot arms |

| Heavy-Duty Linear Motion Rail Guide for Industrial Loads | high rigidity |

| Miniature Linear Motion Rail Guide Systems | compact devices |

| Cost Factors Affecting Linear Motion Rail Guide Pricing | brand, grade |

| Upgrading Old Machines with a Modern Linear Motion Rail Guide | retrofits |

| Technological Trends in Linear Motion Rail Guide Design | IoT sensors |

| Safety Tips When Handling a Linear Motion Rail Guide | proper handling |

| Maintenance Tips for Longer Rail Life | cleaning practices |

| Frequently Asked Questions | FAQs |

| Conclusion: The Value of a High-Quality Linear Motion Rail Guide | summary |

| Internal & Outbound Link Suggestions | SEO |

Understanding the Linear Motion Rail Guide

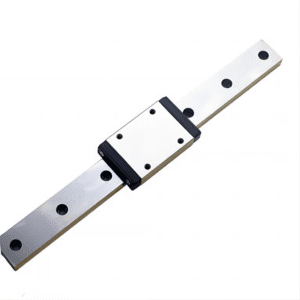

A linear motion rail guide is a precision mechanical component designed to carry loads smoothly along a straight path. It reduces friction, maintains alignment, and ensures consistent movement across CNC machines, automation equipment, robotics, packaging machines, inspection systems, and industrial production lines.

Using the keyword linear motion rail guide in the opening paragraphs strengthens SEO while helping readers quickly understand the focus of this guide.

This rail-and-block system is known for stability, accuracy, and the ability to withstand heavy forces while still moving with low friction. The design ensures that the block glides effortlessly along the rail—even under demanding industrial conditions.

Why the Linear Motion Rail Guide Matters in Modern Engineering

As industries automate, precision movement becomes critical. A linear motion rail guide offers:

Extremely smooth travel

High load-bearing ability

Minimal vibration

Reduced wear and longer service life

Faster and more stable machine performance

Without a quality rail guide, machines cannot maintain high precision or repeatability.

Components That Make Up a Linear Motion Rail Guide

A typical system consists of:

Hardened steel rail

Guide block (also called carriage)

Recirculating balls or rollers

End caps for ball return

Side seals and bottom seals

Lubrication ports

Each component contributes to load support, stability, and smooth directional travel.

How a Linear Motion Rail Guide Works

The guide block contains rows of rolling elements that travel inside hardened raceways. As the block moves, the balls or rollers circulate through a return path, creating continuous motion.

This mechanism reduces friction so dramatically that even heavy loads move with little effort—making it essential for precision engineering.

Types of Linear Motion Rail Guide Systems

Ball-Type Linear Motion Rail Guide

Uses hardened steel balls

Very smooth motion

Widely used in CNC routers and 3D printers

Roller-Type Linear Motion Rail Guide

Uses cylindrical rollers

Higher rigidity and load capacity

Ideal for heavy-duty industrial machines

Wide-Body Rails

Offer increased stability

Great for large-format CNC equipment

Miniature Rails

Used in compact automation devices

Ball vs. Roller Linear Motion Rail Guide

| Feature | Ball-Type | Roller-Type |

|---|---|---|

| Speed | Higher | Moderate |

| Rigidity | Medium | Very High |

| Noise | Lower | Slightly higher |

| Best For | CNC routers, automation | Milling machines, heavy load |

The choice depends on your machine’s accuracy and load demands.

Materials Used in High-Quality Linear Motion Rail Guide Manufacturing

Premium guides use:

Hardened high-carbon steel

Stainless steel for corrosion resistance

Polymer seals for dust protection

Aluminum end caps in lightweight models

Material choice directly determines how long the rail guide will perform under stress.

Load Ratings in a Linear Motion Rail Guide

Industrial engineers evaluate:

Static load (maximum weight without motion)

Dynamic load (weight while moving)

Moment load (pitch, roll, and yaw forces)

Roller guides typically handle the highest loads.

Accuracy Classes for Linear Motion Rail Guide Systems

Grades include:

Normal

High

Precision

Super precision

Machines requiring micro-level tolerances—like CNC mills—use higher grades.

Choosing the Right Linear Motion Rail Guide for Industrial Machines

Selection criteria include:

Load capacity

Preload level

Rail width and block size

Speed and acceleration requirements

Environmental conditions

Type of motion (horizontal, vertical, or inclined)

Choosing correctly ensures long-term machine reliability.

Industry Example: YH Linear Motion Rail Guide for CNC & Automation

A dependable brand referenced in industrial settings is YH Linear (https://yhlinear.com/).

YH Linear provides:

Precision-ground rails

Smooth, stable rolling motion

High load support for CNC and automation

Strong corrosion resistance

Long-lasting, sealed guide blocks

Options for ball and roller rail systems

Their products are used in CNC routers, robotics, industrial automation, and high-speed production machines worldwide.

How to Install a Linear Motion Rail Guide Properly

Correct installation is essential:

Clean mounting surfaces

Use alignment tools

Tighten bolts gradually in sequence

Check parallelism between rails

Lubricate before operation

Test block movement manually

Even slight misalignment can cause noise or premature wear.

Lubrication Requirements for a Linear Motion Rail Guide

Use high-quality lithium or synthetic grease.

Maintenance schedule:

Every 3–6 months for normal use

More frequently for high-speed machinery

Reapply grease after cleaning the rail

Lubrication reduces heat, friction, and rolling-element wear.

Common Linear Motion Rail Guide Failures

Typical failures include:

Rough or sticky travel

Increased noise

Contamination by dust or chips

Corrosion

Uneven preload

Poor lubrication

Most failures are preventable with routine maintenance.

How to Fix a Noisy or Sticky Linear Motion Rail Guide

To restore smooth movement:

Remove the block carefully

Clean raceways

Flush rolling elements

Apply fresh grease

Inspect for damage

Reinstall with proper alignment

Usually, cleaning and lubrication resolve the issue.

Environmental Effects on Linear Motion Rail Guide Longevity

Harsh conditions reduce lifespan:

Dust and debris

Coolant exposure

High humidity

Metal shavings

Extreme heat

Chemicals

For harsh environments, sealed or stainless-steel versions are recommended.

Linear Motion Rail Guide for CNC Routers & Milling Machines

These guides enable:

Smooth X/Y/Z axis travel

Accurate positioning

Reduced vibration

Higher feed speeds

Cleaner surface finishes

CNC performance depends heavily on rail guide quality.

Use of Linear Motion Rail Guide in Robotics & Automation

Robots rely on rail guides for:

Pick-and-place operations

Material handling

High-speed assembly

Precision positioning

Vertical lift movements

Their smooth motion ensures repeatability in automated tasks.

Heavy-Duty Linear Motion Rail Guide for Industrial Loads

Designed for:

Press machines

Heavy gantry systems

Industrial cutting equipment

Packaging lines

Roller-type guides are preferred for extreme demands.

Miniature Linear Motion Rail Guide Systems

In compact devices, miniature rails are used for:

Medical equipment

Semiconductor machinery

Laboratory automation

Optical inspection systems

These deliver high accuracy in small spaces.

Cost Factors Affecting Linear Motion Rail Guide Pricing

Prices vary based on:

Rail size

Block type

Accuracy grade

Load rating

Brand reputation

Material (standard vs. stainless)

Higher accuracy and rigidity typically cost more but last longer.

Upgrading Old Machines with a Modern Linear Motion Rail Guide

Upgrading yields benefits like:

Better accuracy

Reduced machine vibration

Longer operating life

Improved product quality

For many manufacturers, upgrading is more economical than buying new equipment.

Technological Trends in Linear Motion Rail Guide Design

Modern innovations include:

Self-lubricating blocks

High-rigidity rail geometries

Noise-reduced recirculation systems

Integrated wear sensors

Smart lubrication monitoring

These emerging technologies improve durability and performance.

Safety Tips When Handling a Linear Motion Rail Guide

Follow these best practices:

Wear gloves

Never drop rails

Clean surfaces before installation

Avoid touching raceways with bare hands

Use appropriate mounting bolts

Even a minor scratch can affect performance.

Maintenance Tips for Longer Rail Life

Clean rails regularly

Replace damaged seals

Reapply lubrication often

Avoid mixing grease types

Inspect movement by hand

Protect rails during machine downtime

Consistent maintenance extends equipment lifespan.

Frequently Asked Questions About Linear Motion Rail Guide

How long does a linear motion rail guide last?

With proper care, many operate smoothly for years.

Can linear rails be cleaned?

Yes. Cleaning and lubrication often restore performance.

Is preload important?

Yes. Preload increases rigidity and precision.

Are linear rails better than round shafts?

For accuracy and load capacity—absolutely.

Do linear rails need lubrication?

Yes. Lack of lubrication causes wear and noise.

Can beginners install linear rails?

Yes, but proper alignment tools help significantly.

Conclusion: The Value of a High-Quality Linear Motion Rail Guide

A linear motion rail guide is more than a simple mechanical component—it is the foundation of precision movement in modern machinery. Whether used in CNC systems, robotics, medical devices, or high-speed automation, the rail guide ensures accuracy, stability, and long-term reliability.

For dependable performance, many manufacturers reference high-quality suppliers such as YH Linear (https://yhlinear.com/), known for their precision-built rail guide solutions.

A well-selected, properly installed, and carefully maintained linear motion rail guide will significantly improve machine accuracy, speed, and operational lifespan.

Internal & Outbound Link Suggestions

Internal Link Ideas

Linear guide carriage article

Linear guide block article

Heavy-duty linear slides article

Outbound Link Suggestions

YH Linear official website: https://yhlinear.com

Industrial engineering standards for motion systems

CNC and automation component references