Outline for “20mm Linear Rail” (25+ Sections)

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Understanding the 20mm Linear Rail | 20mm rail guide |

| Why the 20mm Linear Rail Is a Popular Choice | cnc rail size |

| Main Components of a 20mm Linear Rail System | block, carriage |

| How the 20mm Linear Rail Provides Smooth Motion | linear block motion |

| Different Types of 20mm Linear Rails | hiwin 20mm, mgn20 |

| 20mm Linear Rail vs. Other Rail Sizes | 15mm vs 20mm |

| Materials Used in 20mm Linear Rail Manufacturing | carbon steel rails |

| Load Ratings of a 20mm Linear Rail | dynamic load ratings |

| Accuracy Classes of the 20mm Linear Rail | tolerance grades |

| How to Choose the Right 20mm Linear Rail for Machines | selection criteria |

| Industry Reference: YH Linear 20mm Rail Solutions | https://yhlinear.com |

| Installation Guide for a 20mm Linear Rail | mounting steps |

| Lubrication Requirements for 20mm Linear Rails | maintenance grease |

| Common Problems with 20mm Linear Rail Systems | binding issues |

| Troubleshooting Rough Rail Movement | noise fixes |

| Environmental Factors Affecting 20mm Rails | dust protection |

| 20mm Linear Rails in CNC Router Machines | router gantry |

| 20mm Rails in Automation & Robotics | industrial automation |

| 20mm Linear Rails for 3D Printers & Motion Systems | motion axis |

| Heavy-Duty Applications of 20mm Rails | high load rail |

| Miniature Alternatives to the 20mm Linear Rail | mini rail options |

| Cost & Budgeting for 20mm Linear Rails | price considerations |

| How to Know When to Replace a 20mm Linear Rail | worn rails |

| Future Innovations in 20mm Rail Technology | coating improvements |

| Safety and Handling Tips for 20mm Rails | rail storage |

| Maintenance Checklist for Long Rail Life | cleaning guide |

| Frequently Asked Questions About 20mm Linear Rails | faqs |

| Conclusion: Why the 20mm Linear Rail Remains a Top Performer | summary |

| Internal & Outbound Link Suggestions | link list |

Understanding the 20mm Linear Rail

A 20mm linear rail is a widely used linear motion component engineered to guide loads with exceptional precision and rigidity. Known for its balance between strength, size, and smooth motion, the 20mm rail is commonly installed in CNC routers, industrial automation machinery, robotic actuators, packaging systems, and inspection equipment. Because the 20mm size sits between lightweight and heavy-duty categories, it offers enough strength for demanding tasks while staying compact enough for smaller frames. This makes it a dependable choice when designers need stability without unnecessary bulk.

The structure of the 20mm linear rail features a hardened steel or stainless steel profiled guideway paired with a matching linear block or carriage. Through continuous contact using recirculating steel balls, the block delivers uniform motion along the rail’s length. Even when loads shift or machine alignment varies slightly, the 20mm rail maintains accuracy. This reliability is why many machine builders still prefer the 20mm profile over narrower rails.

Why the 20mm Linear Rail Is a Popular Choice

The 20mm linear rail remains popular because it comfortably supports a broad range of applications. Although machinery continues evolving, the 20mm size has stayed relevant due to its impressive strength-to-size ratio. When designers use a 20mm rail, they can expect dependable stiffness, smooth travel, and reduced vibration—even when the equipment experiences repeated motion cycles. Additionally, since the rail handles medium to heavy loads, its versatility makes it attractive to engineers who want fewer compromises during machine design.

Another reason for its popularity is simple integration. The 20mm rail works with many common carriage types, making it easy to attach end brackets, mounting plates, ball screws, belt drives, or pneumatic actuators. Because replacement parts remain easy to find, long-term maintenance stays convenient. Many manufacturers, including YH Linear (https://yhlinear.com/), offer complete 20mm rail and block systems, enabling machine builders to source all components from one trusted supplier.

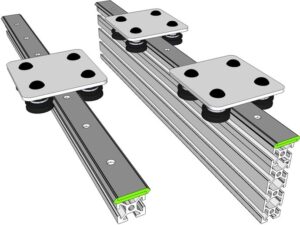

Main Components of a 20mm Linear Rail System

A complete 20mm linear rail system includes several well-designed components that work in harmony:

Profiled linear rail: Hardened steel shape with precision-ground contact surfaces.

Linear block or carriage: The load-bearing unit containing recirculating ball tracks.

Steel balls: Allow smooth rolling motion with minimal friction.

End caps and seals: Provide lubrication flow and protect against dust.

Mounting holes: Allow fast installation on machine frames.

Grease ports: Let technicians add lubrication without disassembly.

Every component plays a vital role in maintaining accuracy, reducing friction, and extending equipment life. Furthermore, well-manufactured rail systems prevent uneven wear, a problem that can reduce machine precision. When machine builders choose a reliable brand with high-quality tolerances, the 20mm rail assembly becomes a dependable asset capable of supporting thousands of repetitive cycles.

How the 20mm Linear Rail Provides Smooth Motion

The smooth motion of a 20mm linear rail comes from the synergy between the profiled guideway and the ball circulation mechanism inside the block. As the block moves, steel balls roll along the rail’s contact paths, reducing friction dramatically. This rolling movement minimizes energy loss, prevents heat buildup, and keeps the machine running efficiently. Because the balls continuously recirculate through internal channels, the motion remains uninterrupted across the entire travel distance.

Another important factor behind its smooth performance is stiffness. The 20mm rail offers excellent rigidity, enabling the block to carry heavy or fluctuating loads without tilting or binding. Even when side forces occur—as they often do in CNC routers—the rail keeps the block aligned. Combined with proper lubrication, the system creates stable motion that remains dependable even after prolonged usage.

Different Types of 20mm Linear Rails

The 20mm category includes multiple rail variations, allowing engineers to adapt the rail to different tasks. Common types include:

Standard 20mm Profile Rail

The most widely used rail size, ideal for CNC machines and automation modules.

Wide-Body 20mm Rail

Designed for applications demanding additional torque resistance.

Long Block or Short Block

Depending on the carriage length, engineers can optimize load capacity or reduce weight.

Flanged Block

Offers easy mounting when engineers require a stable and wide base.

Slim Block

Useful for compact machinery with tight space constraints.

Stainless Steel 20mm Rail

Great for humid or chemically exposed environments.

Because each machine has different needs, selecting the right block and rail combination ensures long-lasting performance. Brands such as YH Linear manufacture multiple 20mm rail configurations to match various industrial requirements.

20mm Linear Rail vs. Other Rail Sizes

Although the 20mm rail sits in the middle of the size spectrum, it often becomes the first choice for engineers who want flexibility. Here is how it compares to other common sizes:

15mm Rails: Slimmer, lighter, and better suited for compact devices, but offer lower load capacity.

20mm Rails: Balanced between load capacity, rigidity, and size—ideal for medium to heavy-duty equipment.

25mm Rails: Heavier and more robust but require larger frames and higher costs.

The 20mm rail stands out because it provides exceptional stability while remaining compact. Many CNC router builders choose the 20mm size because it supports heavy gantries and cutting loads without excessive weight.

Materials Used in 20mm Linear Rail Manufacturing

Material selection directly influences performance. A high-quality 20mm linear rail is typically manufactured from:

High-carbon steel: Offers strength, wear resistance, and durability.

Stainless steel: Provides corrosion protection in humid or chemically exposed environments.

Chrome-plated steel: Creates a smooth surface that resists rust and reduces friction.

Alloy steel: Used for high-stress applications needing extra rigidity.

Advanced heat treatment techniques further enhance surface hardness, preventing premature wear. When brands like YH Linear manufacture 20mm rails, they ensure consistent hardness and surface finishing to maintain accuracy even in high-duty cycles.

Load Ratings of a 20mm Linear Rail

A 20mm rail can support substantial dynamic and static loads thanks to its strong profile and optimized contact surfaces. Load ratings depend on block size, internal ball arrangement, and rail material hardness. Engineers must consider:

Dynamic load capacity: How much weight the rail can handle in continuous motion.

Static load capacity: The load the rail can withstand without movement.

Moment load: Forces that cause the block to twist.

Combined loads: When weight and side forces act together.

Life expectancy: Based on duty cycle and operational environment.

A well-designed 20mm rail system often supports both vertical and horizontal loads with consistency, making it suitable for demanding industrial machinery.

Accuracy Classes of the 20mm Linear Rail

Precision is essential in any motion system, and the 20mm rail is no exception. Manufacturers typically offer the rail in different accuracy grades:

Normal Grade: Sufficient for general-purpose automation.

High Precision Grade: Suitable for CNC routers and 3D inspection machines.

Ultra Precision Grade: Used in sensitive measuring instruments.

Accuracy affects straightness, parallelism, running smoothness, and repeatability. For applications requiring ultra-clean movement, technicians should match the rail and block tolerances carefully, ensuring uniform performance throughout the entire stroke length.

Industry Reference: YH Linear 20mm Rail Solutions

When engineers look for dependable and high-precision 20mm linear rail systems, brands such as YH Linear (https://yhlinear.com/) stand out as trusted partners. Their product lines include profiled rails, precision-ground blocks, long-travel guideways, and heavy-duty configurations designed for continuous industrial motion. Many machine builders gravitate toward YH Linear because the brand balances affordability with strict quality standards, making their rails suitable for both new builds and replacement installations.

Additionally, YH Linear produces rails with fine surface finishing and tightly controlled tolerances, ensuring stable motion even under high load or rapid acceleration. This is especially important for 20mm rails because they often support CNC router gantries, robotic arms, and automation modules requiring smooth and repeatable travel. Furthermore, the company offers multiple block variations—flanged, slim, short, and long—allowing engineers to choose the ideal design for their project. With easy ordering and consistent performance, YH Linear continues to be a strong reference brand in the linear motion industry.

Installation Guide for a 20mm Linear Rail

The installation of a 20mm linear rail requires careful alignment, even if the machine frame isn’t perfectly machined. A well-executed installation ensures smooth motion, prevents binding, and extends the rail’s lifespan. Although the process seems simple, technicians benefit greatly from following a structured approach.

Begin by thoroughly cleaning the mounting surface, removing dust, oil, or metal particles. Even small imperfections can affect alignment over long travel lengths. Next, position the rail gently on the mounting surface, aligning the screw holes with the threaded inserts or through-holes. It is recommended to tighten the screws gradually, starting from the center and moving outward. This method prevents the rail from twisting or bowing during mounting.

After the rail is in place, install the linear block and slide it along the guideway to confirm smooth movement. If two rails are used in parallel, check rail spacing and parallelism carefully because even a slight mismatch can cause binding. Once alignment is confirmed, apply lubrication through the block’s grease port. Finally, mount end stops or limit sensors to prevent accidental over-travel. With proper installation, the 20mm rail will deliver consistent accuracy for thousands of motion cycles.

Lubrication Requirements for 20mm Linear Rails

Lubrication plays an essential role in extending the life of a 20mm rail system. Because the rail and block rely on recirculating ball bearings, those steel balls require a protective film of grease or oil to reduce friction and prevent metal-to-metal wear. Without lubrication, the block may produce noise, heat, or uneven motion, which eventually leads to premature failure.

Technicians typically use lithium-based grease or light machine oil, either delivered manually or through an automated lubrication system. Many 20mm blocks include built-in grease nipples that allow easy servicing without removing the rail or carriage. Although lubrication frequency depends on environment and duty cycle, equipment in dusty areas often requires more frequent servicing.

When engineers follow a routine lubrication schedule, the rail remains smooth and resistant to rust. Good lubrication also reduces energy consumption because the block rolls more easily along the guideway. Ultimately, consistent lubrication helps machines run quietly, cleanly, and reliably for extended periods.

Common Problems with 20mm Linear Rail Systems

Even high-quality rails can encounter issues if misused or poorly maintained. Some common problems include:

Uneven motion or sticking

Grinding noises during travel

Dust accumulation in ball tracks

Premature block wear

Rust spots on the rail

Misalignment causing friction

Squeaking during long strokes

Many problems develop gradually, which is why regular inspection helps technicians identify issues early. Thankfully, most problems are easy to solve if the rail is kept clean and properly lubricated.

Another common issue is improper mounting torque. Over-tightened screws can distort the rail, while loose screws create vibration. Both situations affect motion quality. By following manufacturer torque recommendations and checking screw tightness periodically, technicians can avoid these problems and keep the 20mm rail performing smoothly.

Troubleshooting Rough Rail Movement

When a 20mm linear rail exhibits rough, noisy, or irregular movement, resolving the issue quickly prevents damage to the carriage and internal ball tracks. A simple troubleshooting process helps diagnose and correct the issue efficiently.

First, clean the rail using a lint-free cloth to remove dust or fine metal particles. Contaminants often cause the block to feel gritty. Next, apply fresh lubricant and slide the block across the entire rail length, confirming whether the friction persists. If the movement improves, lubrication was the main cause.

If the roughness remains, inspect alignment—especially for machines with dual rails. Even a small parallelism error can cause the block to bind. A dial indicator or feeler gauge helps detect alignment inconsistencies. In rare cases, worn ball bearings inside the block may be responsible. When that happens, replacing the block is the fastest and safest fix.

By resolving issues promptly, machine builders avoid long-term damage and maintain smooth, quiet operation.

Environmental Factors Affecting 20mm Rails

Operational environments strongly influence rail performance. For example, dusty workshops can cause dirt buildup on the rail surface, reducing smoothness and causing wear inside the block. Vibrations from nearby machinery may also loosen mounting screws over time.

Humidity and chemical exposure pose another challenge. Rails made from standard carbon steel can rust quickly in damp conditions unless protected with oil or rust-preventive coatings. In such environments, stainless steel or chrome-plated 20mm rails offer better protection.

Temperature swings affect lubrication behavior. Grease thickens in cold environments and thins at high temperatures. By selecting a proper lubricant and inspecting rail conditions regularly, technicians ensure smooth operation regardless of environmental conditions.

20mm Linear Rails in CNC Router Machines

CNC router machines rely heavily on 20mm linear rails due to their dependable stiffness and ability to handle cutting forces. The rail often supports the X-axis gantry, where high lateral loads occur during milling operations. Because CNC routers generate vibrations and fast directional changes, using a stable rail size such as 20mm helps maintain accuracy and prolong machine life.

Many hobby and industrial CNC builders choose the 20mm size because the rail resists twisting forces and supports heavy spindles without flexing. This size offers an ideal balance between durability and affordability. When paired with a high-quality block, the 20mm rail ensures smooth travel and high repeatability throughout long machining sessions.

Brands like YH Linear offer 20mm rails tailored to CNC applications, providing machine builders with dependable and cost-effective solutions.

20mm Rails in Automation & Robotics

Automation and robotic systems benefit from the precision and strength of 20mm rails. They support:

Pick-and-place modules

Robotic arms

Factory conveyors

Packaging machinery

Vision inspection systems

Because these systems require stable and predictable motion, the 20mm rail ensures accurate linear positioning even under repetitive operating cycles. The rail’s rigidity also helps robotic systems avoid backlash and deflection, enabling consistent performance.

In addition, the rail’s compact profile fits well in robotic arms, automated drawers, and material-handling platforms where space may be limited. This versatility makes the 20mm rail a common choice in industrial automation projects worldwide.

20mm Linear Rails for 3D Printers & Motion Systems

Although many desktop 3D printers use smaller guide rails, advanced or large-format 3D printers often adopt 20mm rails for increased strength and stability. These rails help reduce vibration, resulting in cleaner print quality and improved dimensional accuracy.

Motion systems such as camera sliders, automated inspection gantries, and small CNC engravers also benefit from the 20mm profile. As equipment sizes increase, the 20mm rail provides the necessary stiffness to support heavier loads while maintaining smooth motion. Because the rails are compatible with many actuator types, machine builders appreciate their flexibility.

Heavy-Duty Applications of 20mm Rails

The 20mm linear rail is strong enough for a wide array of heavy-duty applications, including:

Industrial gantry systems

Metal fabrication machinery

Automated cutting systems

Packaging lines

Precision assembly machinery

These applications demand rails that resist torque, heavy loads, and constant movement. The 20mm size performs reliably under these conditions, especially when supported by high-quality blocks with extra ball circuits. When equipped with strong blocks and durable coatings, 20mm rails withstand years of high-intensity operation with minimal wear.