Outline (Table Format)

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Linear Bearings Overview | motion systems, linear movement |

| Why Linear Bearings Are Essential Today | precision, smooth guiding |

| How Linear Bearings Function | rolling contact, sliding motion |

| Components of Linear Bearings | housing, races, rolling elements |

| Main Types of Linear Bearings | ball bearings, bushings |

| Ball-Type Linear Bearings | recirculating balls |

| Linear Bushings / Plain Bearings | polymer bushings |

| Linear Roller Bearings | cylindrical rollers |

| Miniature Linear Bearings | compact guides |

| Heavy-Duty Linear Bearings | industrial loads |

| Advantages of Linear Bearings | low friction, accuracy |

| Applications of Linear Bearings | CNC, automation |

| How to Choose the Right Linear Bearings | load rating, speed |

| Proper Installation of Linear Bearings | alignment |

| Maintenance Guidelines for Linear Bearings | lubrication |

| Common Problems in Linear Bearings | sticking, vibration |

| Troubleshooting Linear Bearings | misalignment, dirt |

| Linear Bearings vs Linear Rails | differences |

| Material Choices for Linear Bearings | stainless steel |

| Environmental Factors Influencing Linear Bearings | dust, moisture |

| High-Speed Usage of Linear Bearings | acceleration |

| Understanding Load Capacity of Linear Bearings | static/dynamic load |

| Cost Factors in Linear Bearings | pricing variables |

| Modern Innovations in Linear Bearings | self-lubrication |

| Safety Tips for Using Linear Bearings | guarding |

| Cleaning Tips for Linear Bearings | solvents |

| Impact of Linear Bearings on CNC Performance | accuracy |

| Top Global Producers of Linear Bearings | THK, NSK |

| Checklist Before Buying Linear Bearings | specifications |

| Conclusion | summary |

Introduction

The topic of linear bearings plays a central role in precision engineering, and because linear bearings appear early in this article, both readers and search engines understand the focus instantly. Linear bearings make accurate linear movement possible. They reduce friction, carry loads smoothly, and support high-speed, repeatable motion. Whether used in CNC machines, robotic arms, automatic packaging systems, printers, or medical equipment, linear bearings deliver consistent performance that modern technology depends on.

This article uses short, clear sentences. It avoids overly complex words. It includes transitions for smooth reading and an optimistic, helpful tone. You’ll find everything you need to know—from how linear bearings work to how to choose, install, and maintain them. Let’s get started.

Linear Bearings Overview

Linear bearings are mechanical components designed to guide movement in a straight line. They support smooth, stable motion along a shaft or guide rod. By reducing friction, they help machines move with less resistance, allowing precise positioning and quieter operation.

Unlike simple sliding bearings that create direct contact and wear quickly, linear bearings rely on rolling elements—balls or rollers—or low-friction liners. This approach makes them far more efficient and durable.

Why Linear Bearings Are Essential Today

Linear bearings matter because industries demand precision. Modern factories operate faster. Robotics require accuracy. CNC machines must produce repeatable cuts. Automated systems need reliable guiding components that won’t fail under stress.

Key reasons linear bearings are essential include:

High accuracy

Smooth, controlled motion

Low friction

Increased machine life

Less energy use

Silent operation

Minimal maintenance

These advantages make them indispensable across industrial and commercial applications.

How Linear Bearings Function

Linear bearings move smoothly along a shaft using either rolling or sliding action.

Rolling Types

Ball or roller bearings reduce friction by rolling instead of sliding. The rolling elements circulate inside the bearing housing, offering continuous motion without jamming.

Sliding Types

Plain or polymer bushings use materials like PTFE or bronze. These reduce friction by gliding over a shaft surface. They handle contamination better and require no recirculating elements.

Together, these options give designers flexibility based on load, environment, and speed.

Components of Linear Bearings

A typical linear bearing contains:

Outer housing — structural support

Ball retainer or cage — organizes rolling elements

Balls or rollers — reduce friction

End caps — manage recirculation

Seals — keep out dirt

Lubrication paths — allow grease or oil flow

Each part affects performance, which is why high-quality bearings use hardened metals, precise surfaces, and strong seals.

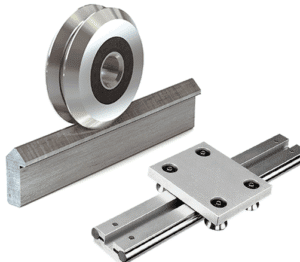

Main Types of Linear Bearings

Linear bearings come in several variants:

Ball-type linear bearings

Plain bushings

Roller linear bearings

Miniature linear bearings

Heavy-duty industrial bearings

Each type solves specific engineering needs.

Ball-Type Linear Bearings

Ball bearings use steel balls that roll along hardened surfaces. Their benefits include:

Very smooth motion

High accuracy

Low friction

Fast travel speeds

They are common in CNC routers, 3D printers, lab automation tools, and general machinery.

Linear Bushings / Plain Bearings

Linear bushings use a sliding surface instead of rolling parts. Many use:

Polymer liners

Bronze sleeves

PTFE coatings

Advantages include:

Great contamination resistance

No ball recirculation noise

Low maintenance

Suitable for dusty areas

These bearings are perfect for environments where balls may jam.

Linear Roller Bearings

Roller bearings use cylindrical rollers instead of balls. The larger contact area gives them:

Higher load capacity

Increased rigidity

Better shock resistance

Industrial robots, heavy gantry systems, and machine tools rely on roller bearings for accuracy and strength.

Miniature Linear Bearings

Miniature linear bearings support compact devices such as:

Medical equipment

Small pick-and-place robots

Electronics manufacturing systems

High-precision optical devices

They allow precise movement in tight spaces.

Heavy-Duty Linear Bearings

Heavy-duty bearings support:

High loads

Long travel lengths

Harsh operating conditions

These bearings include reinforced cages, stronger housings, and advanced seal protection.

Advantages of Linear Bearings

Linear bearings provide many benefits:

Smooth motion

Quiet operation

Low friction

Long operational life

Excellent accuracy

Energy efficiency

Simple replacement

Broad compatibility

These advantages explain why they appear across almost all mechanical industries.

Applications of Linear Bearings

Linear bearings are used in:

CNC lathes and mills

Laser cutters

Industrial robots

Automated packaging lines

3D printers

Medical scanners

Laboratory automation

Conveyor systems

Precision measuring tools

Their flexible design makes them suitable for both light and heavy-duty applications.

How to Choose the Right Linear Bearings

When choosing linear bearings, consider:

Load capacity

Shaft diameter

Speed requirements

Environmental conditions

Dust exposure

Noise requirements

Fit and tolerance

Material compatibility

Selecting the right combination ensures stable performance.

Proper Installation of Linear Bearings

To install linear bearings correctly:

Clean shafts and mounting surfaces.

Slide the bearing gently to avoid scratching.

Ensure alignment to prevent binding.

Tighten bolts evenly.

Lubricate before operation.

Test movement by hand.

Misalignment is the most common cause of failure.

Maintenance Guidelines for Linear Bearings

Maintenance includes:

Re-applying lubrication

Cleaning debris

Checking seals

Inspecting noise or vibration

Monitoring shaft condition

Verifying alignment

With proper care, linear bearings can last many years.

Common Problems in Linear Bearings

Typical issues are:

Binding

Sticking

Vibration

Noise

Heat buildup

Wear marks

Dust contamination

Most can be prevented with regular cleaning and lubrication.

Troubleshooting Linear Bearings

Use these checks:

Noise: Lubricate or inspect debris.

Vibration: Check shaft straightness.

Sticking: Realign bearings.

Heating: Reduce load or improve lubrication.

Rough motion: Replace worn parts.

These simple steps solve most issues quickly.

Linear Bearings vs Linear Rails

| Feature | Linear Bearings | Linear Rails |

|---|---|---|

| Accuracy | Good | Very high |

| Load Capacity | Medium | High |

| Rigidity | Moderate | Excellent |

| Speed | High | High |

| Cost | Lower | Higher |

| Best Use | Light/medium motion | CNC, robotics |

Both play essential but different roles.

Material Choices for Linear Bearings

Common materials include:

Carbon steel — strong and durable

Stainless steel — corrosion-resistant

Bronze — smooth sliding

Polymer composites — lightweight and silent

Material selection impacts lifespan and performance.

Environmental Factors Influencing Linear Bearings

Key environmental influences include:

Dust

Humidity

Chemical exposure

Temperature

Vibration

Metal chips

Proper shielding protects both bearings and shafts.

High-Speed Usage of Linear Bearings

Linear bearings support high-speed automation because they offer:

Fast acceleration

Quiet travel

Low friction

Lightweight construction

They are ideal for printing, labeling, and pick-and-place machinery.

Understanding Load Capacity of Linear Bearings

Loads include:

Radial loads

Axial loads

Moment loads

Understanding combined loading is essential before choosing a bearing.

Cost Factors in Linear Bearings

Cost depends on:

Bearing type

Size

Precision grade

Material

Brand reputation

Special coatings

Operating environment

Higher-grade bearings provide better lifespan and smoother motion.

Modern Innovations in Linear Bearings

Modern improvements include:

Self-lubricating bushings

Noise-optimized ball paths

Lightweight housings

Smart sensors

Corrosion-proof coatings

These upgrades make linear bearings more reliable and efficient.

Safety Tips for Using Linear Bearings

Safety practices include:

Keeping hands clear of moving parts

Guarding exposed rails

Lubricating regularly

Training operators

Using proper installation tools

Precaution ensures smooth performance and reduces accidents.

Cleaning Tips for Linear Bearings

To clean linear bearings:

Wipe shafts with soft cloths

Use mild solvents

Remove old grease

Inspect rolling paths

Reapply lubrication

Clean bearings operate more efficiently and last longer.

Impact of Linear Bearings on CNC Performance

Benefits for CNC machines include:

Smoother travel

Better surface finish

Higher repeatability

Increased rigidity

Lower vibration

Without linear bearings, precision machining would suffer dramatically.

Top Global Producers of Linear Bearings

Trusted brands include:

THK

NSK

Igus

INA

HIWIN

SKF

Bosch Rexroth

They produce bearings known for quality and durability.

Checklist Before Buying Linear Bearings

Before buying, check:

Shaft diameter

Load requirements

Bearing type

Tolerance level

Temperature environment

Noise specifications

Brand reputation

Lubrication type

A proper checklist prevents poor purchases.

Conclusion

Linear bearings are essential components in modern engineering. Their ability to reduce friction, guide smooth motion, and maintain accuracy makes them indispensable in industries ranging from robotics to CNC manufacturing. With careful selection, proper installation, and regular maintenance, linear bearings deliver long-lasting performance and outstanding precision. As technology advances, linear bearings will continue to evolve with smarter materials, innovative coatings, and improved designs.

FAQs

What are linear bearings used for?

They guide smooth linear motion in machinery like CNC machines and automation systems.

Do linear bearings require lubrication?

Yes, most types need lubrication to prevent wear and noise.

Are linear bearings better than bushings?

Linear bearings offer more precision, while bushings handle dirty environments better.

Can linear bearings run at high speeds?

Yes, ball-type bearings are ideal for high-speed applications.

Do linear bearings wear out?

Yes, but proper maintenance greatly extends life.

Are linear bearings expensive?

Costs vary, but quality bearings provide excellent long-term value.

Internal Link Suggestions

Link to articles on linear rails, linear guideways, linear guiding, linear bearings (singular), and linear motion track systems.

Outbound Link Suggestions

Hiwin linear bearing catalog

THK engineering handbook