Introduction

In modern mechanical engineering and industrial automation, smooth and controlled linear motion is essential for efficiency, accuracy, and durability. One important component that supports this requirement is the roll rail. Roll rails are widely used in applications where low friction, high load capacity, and smooth rolling motion are required.

Compared with traditional sliding guides, roll rails rely on rolling contact, which significantly reduces friction and wear. As a result, they are commonly found in material handling systems, industrial machinery, automation equipment, heavy-duty transport mechanisms, and precision motion systems.

This article provides a comprehensive explanation of roll rails, including their definition, structure, working principle, types, materials, advantages, applications, selection considerations, installation, and maintenance.

What Is a Roll Rail?

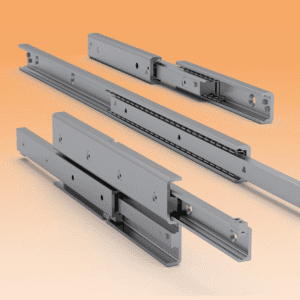

A roll rail is a linear guiding component designed to support and guide motion using rolling elements, such as rollers or wheels, instead of sliding surfaces. It typically works together with rollers, cam followers, or rolling carriages that move along the rail.

The main functions of a roll rail are:

To guide linear motion smoothly

To reduce friction and energy loss

To support heavy or dynamic loads

To ensure stable and repeatable movement

Roll rails are especially suitable for systems that require long travel distances, high load capacity, or continuous operation.

Key Components of a Roll Rail System

1. Roll Rail Profile

The main guiding track

Usually made of hardened steel or high-strength aluminum

Designed to provide a precise rolling surface

2. Rolling Elements

Rollers, wheels, or cam followers

Provide rolling contact instead of sliding contact

Reduce friction and wear

3. Carriage or Support Frame

Holds the rolling elements

Transfers load from the moving structure to the rail

4. Mounting Base

Fixes the roll rail securely to the machine structure

Ensures alignment and rigidity

5. Optional Covers and Seals

Protect the rail from dust, debris, and contamination

Extend service life

How a Roll Rail Works

Roll rails operate on the principle of rolling friction, which is significantly lower than sliding friction:

The roll rail is mounted on a rigid, flat surface.

Rollers or wheels are positioned to run along the rail profile.

As the load moves, the rollers rotate instead of sliding.

Friction and heat generation are minimized.

Smooth and efficient linear motion is achieved, even under heavy loads.

This design allows roll rail systems to handle high loads with minimal resistance, making them ideal for industrial environments.

Types of Roll Rails

1. V-Guide Roll Rails

V-shaped rail profile

Used with V-groove rollers

High self-centering capability and stability

2. Flat Roll Rails

Flat or slightly profiled rail surface

Used with cylindrical rollers or wheels

Simple design and flexible mounting

3. U-Profile Roll Rails

U-shaped cross-section

Rollers run inside the rail

Provides guidance and protection from contamination

4. Heavy-Duty Roll Rails

Designed for high loads and shock resistance

Thick rail profiles and large rollers

Used in industrial transport and material handling

5. Precision Roll Rails

Tight manufacturing tolerances

Smooth rolling surfaces

Used in applications requiring accurate positioning

Materials Used in Roll Rails

Hardened Carbon Steel – High load capacity and wear resistance

Stainless Steel – Corrosion resistance for harsh or humid environments

Aluminum Alloy – Lightweight, corrosion-resistant, easy to install

Surface Treatments – Induction hardening, chrome plating, anodizing

Material choice depends on load, environment, speed, and required service life.

Advantages of Roll Rails

Very Low Friction Compared to Sliding Guides

High Load Capacity

Smooth and Quiet Operation

Energy-Efficient Motion

Long Service Life with Minimal Wear

Suitable for Long Travel Distances

Flexible Design and Easy Integration

These benefits make roll rails ideal for continuous-duty and heavy-load systems.

Applications of Roll Rails

Roll rails are widely used in:

Material Handling Systems – Conveyors, transfer units

Industrial Automation – Linear transport modules

Machine Tools – Auxiliary axes and support systems

Warehouse and Logistics Equipment

Heavy Machinery and Fabrication Equipment

Packaging and Assembly Lines

Doors, Gates, and Industrial Sliding Systems

How to Choose the Right Roll Rail

When selecting a roll rail, consider the following factors:

Load Capacity – Static and dynamic loads

Travel Length – Required stroke and system size

Speed and Duty Cycle – Continuous or intermittent motion

Precision Requirements – Standard or precision-grade rails

Environmental Conditions – Dust, moisture, chemicals

Mounting Space and Alignment Tolerance

Maintenance Requirements

Proper selection ensures stable performance and long-term reliability.

Installation Best Practices

Ensure mounting surfaces are flat and rigid

Align rails accurately to prevent uneven roller wear

Secure rails using recommended fasteners and torque

Check roller preload and spacing

Perform test runs to confirm smooth motion

Correct installation is essential for performance and service life.

Maintenance and Care

Regular inspection of rail surfaces and rollers

Remove dust, debris, and contaminants

Lubricate rolling elements if required

Replace worn rollers promptly to protect the rail

Compared with sliding guides, roll rails generally require less maintenance.

Roll Rail vs. Linear Guide Rail

| Feature | Roll Rail | Linear Guide Rail |

|---|---|---|

| Friction | Very low | Low |

| Load Capacity | High | Medium to high |

| Precision | Medium to high | High |

| Travel Length | Very long | Limited by rail design |

| Maintenance | Low | Moderate |

Roll rails are often preferred for heavy loads and long travel, while linear guide rails are chosen for high-precision positioning.

Future Trends in Roll Rail Technology

Improved Wear-Resistant Coatings

Integrated Damping and Noise Reduction

Hybrid Roll and Guide Systems

Lightweight High-Strength Materials

Smart Monitoring for Industrial Automation

These developments support more efficient and durable motion systems.

Frequently Asked Questions (FAQs)

1. What is a roll rail used for?

Roll rails guide linear motion using rolling elements, reducing friction and supporting heavy loads.

2. Are roll rails suitable for precision applications?

Yes, precision roll rails can provide accurate guidance, though linear guides are better for ultra-high precision.

3. Do roll rails require lubrication?

Some systems do, depending on roller type and operating conditions.

4. Can roll rails handle long travel distances?

Yes, roll rails are ideal for long-stroke and continuous-motion applications.

5. What industries commonly use roll rails?

Material handling, automation, machinery manufacturing, logistics, and industrial transport systems.

Conclusion

A roll rail is a highly efficient solution for smooth, low-friction, and load-bearing linear motion. Its rolling-based design offers excellent durability, energy efficiency, and reliability, especially in heavy-duty and long-travel applications.

By selecting the appropriate roll rail type, ensuring proper installation, and performing routine inspections, manufacturers can achieve stable operation, reduced maintenance costs, and extended service life. As industrial automation continues to grow, roll rails will remain a key component in robust and efficient motion systems.