Introduction

Linear slides are essential components in machinery, providing precise and controlled linear motion. From CNC machines and 3D printers to automation systems and robotics, linear slides ensure moving parts operate smoothly and accurately.

While high-end linear slides deliver high precision, rigidity, and long service life, they often come with a significant cost. For budget-conscious projects, DIY machines, or light-duty applications, cheap linear slides offer a cost-effective alternative without compromising basic functionality.

This article explores what cheap linear slides are, how they work, their types, advantages, limitations, applications, and tips for selecting and maintaining them.

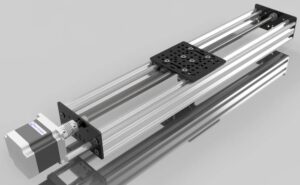

What Is a Cheap Linear Slide?

A cheap linear slide is a linear motion component designed to offer smooth motion at a lower cost. Unlike premium slides:

Materials may be less robust (mild steel, aluminum)

Manufacturing tolerances may be lower

Load capacity and rigidity are reduced

Despite being inexpensive, cheap linear slides provide sufficient linear motion for light-duty applications, making them ideal for hobby projects, small CNC machines, 3D printers, and prototyping systems.

How Does a Cheap Linear Slide Work?

Cheap linear slides operate using basic linear motion principles:

Base Rail – Provides the path for motion

Slide or Carriage – Moves along the rail

Low-Friction Elements – Balls, rollers, or polymer bushings reduce friction

Load Distribution – Bearings or bushings help spread the load

The primary difference from premium linear slides is reduced precision, lower load capacity, and simplified materials or design.

Types of Cheap Linear Slides

Even in budget-friendly options, several types are available:

1. Round Shaft Linear Slides

Cylindrical steel shafts with bushings or bearings

Affordable and simple to install

Moderate load capacity and smoothness

Applications: 3D printers, light CNC machines, DIY automation

2. Ball Bearing Linear Slides

Use recirculating steel balls or simple ball bushings

Smooth motion with moderate precision

Budget versions may have simplified housings

Applications: Light industrial automation, small assembly systems, hobby CNC

3. Miniature Linear Slides

Compact size for limited space applications

Lightweight and low-cost

Moderate load-bearing capacity

Applications: Electronics manufacturing, laboratory equipment, precision prototyping

4. Profiled Linear Slides (Budget)

Rectangular or square rails with a simple carriage

Less rigid than premium versions

Sufficient for low-load tasks

Applications: Light-duty CNC, conveyors, DIY projects, educational kits

Materials Commonly Used in Cheap Linear Slides

Mild Steel: Cost-effective, moderate wear resistance

Aluminum Alloy: Lightweight, inexpensive, easy to machine

Polymer Bushings or Bearings: Reduce friction at low cost

Basic Surface Coatings: Minimal hardening or plating

Material choice impacts durability, load capacity, and smoothness of motion.

Advantages of Cheap Linear Slides

Cost-Effective: Ideal for budget-conscious users

Lightweight and Compact: Suitable for small machines

Sufficient Performance for Light Tasks: Smooth linear motion and moderate precision

Easy to Replace: Low cost reduces maintenance expenses

Limitations of Cheap Linear Slides

Lower Precision: Not suitable for high-accuracy machining

Reduced Load Capacity: Cannot handle heavy loads or shock

Limited Rigidity: May flex under stress

Shorter Lifespan: Materials and manufacturing trade-offs

Frequent Maintenance Needed: Lubrication and inspection required

Understanding these limitations ensures cheap linear slides are used in appropriate applications.

Applications of Cheap Linear Slides

Cheap linear slides are widely used in light-duty and cost-sensitive applications:

3D Printers: Affordable motion guidance for axes

DIY CNC Machines: Low-cost linear motion solution

Light Automation Systems: Pick-and-place, labeling, or small conveyors

Laboratory Equipment: Low-load positioning tasks

Educational Kits and Prototyping: Teaching, research, and experimentation

They provide adequate linear motion without the expense of premium slides.

Cheap Linear Slides vs. Premium Linear Slides

| Feature | Cheap Linear Slide | Premium Linear Slide |

|---|---|---|

| Cost | Low | High |

| Precision | Moderate | High |

| Load Capacity | Light–Medium | Medium–Heavy |

| Rigidity | Moderate | High |

| Lifespan | Shorter | Long |

| Maintenance | Frequent | Low |

Cheap linear slides are ideal for budget projects, while premium slides suit industrial-grade applications.

Tips for Choosing Cheap Linear Slides

Determine Load Requirements: Avoid overloading budget slides

Check Shaft or Rail Quality: Slightly hardened steel or coated surfaces improves durability

Consider Travel Length and Mounting: Ensure compatibility with your machine

Assess Lubrication Needs: Many cheap slides require regular greasing

Understand Precision Needs: Adequate for rough positioning, not high-precision machining

Maintenance Tips for Cheap Linear Slides

Clean rails and bearings regularly to remove dust and debris

Lubricate frequently to reduce friction and wear

Inspect slides for wobble, looseness, or uneven motion

Replace components early to maintain smooth motion

Proper care can extend the lifespan of inexpensive slides significantly.

Frequently Asked Questions (FAQs)

1. Can cheap linear slides be used in CNC machines?

Yes, for light-duty or hobby CNC machines, DIY setups, and 3D printers. They are not recommended for industrial machining.

2. Do cheap linear slides support heavy loads?

No, their load capacity is limited. Heavy-duty or premium slides are required for large loads.

3. Are cheap linear slides durable?

They have a shorter lifespan than premium slides but are sufficient for budget-conscious, light-duty applications.

4. Do cheap linear slides require lubrication?

Yes, regular lubrication is necessary to maintain smooth motion and prevent wear.

5. Where are cheap linear slides commonly used?

They are used in 3D printers, DIY CNC machines, light automation systems, laboratory equipment, and educational or prototyping setups.

Conclusion

Cheap linear slides provide a cost-effective solution for linear motion systems, making them ideal for light-duty machinery, DIY projects, prototyping, and educational applications. While they cannot match premium slides in precision, rigidity, or load capacity, proper selection and maintenance ensure smooth, reliable motion for many budget-conscious applications.

Understanding load limits, precision requirements, and maintenance needs is key to maximizing performance and longevity of cheap linear slides.