In the fields of manufacturing, automation, precision engineering, and robotics, the demand for smooth, accurate, and efficient linear motion has become paramount to ensuring product quality, operational reliability, and production efficiency. A linear sliding bearing—often referred to as a linear plain bearing or linear bushing—is a core component of linear motion systems, designed to enable controlled, low-friction sliding movement along a linear shaft or guide rail. It serves as the interface between the moving load and the fixed shaft/rail, supporting linear displacement while minimizing friction and wear. Unlike rolling linear bearings that use balls or rollers, linear sliding bearings rely on sliding contact (enhanced by low-friction materials or lubrication) to achieve motion, making them ideal for specific applications where simplicity, cost-effectiveness, or contamination resistance is prioritized. This article delves into the intricacies of linear sliding bearings, exploring their core structure, working principles, diverse types, wide-ranging applications, key selection factors, technological advancements, and essential maintenance practices.

1. What is a Linear Sliding Bearing? Definition and Core Concept

A linear sliding bearing is a precision mechanical component that facilitates smooth, constrained linear motion of a load along a fixed linear shaft, guide rail, or guideway. It operates on the principle of sliding friction (as opposed to rolling friction in ball or roller linear bearings), where the bearing’s inner surface glides directly against the outer surface of the shaft or rail. To minimize friction and wear, the bearing’s contact surface is typically lined with low-friction materials, coated with anti-friction films, or designed to retain lubricant. Linear sliding bearings are engineered to withstand radial loads (and in some cases axial or moment loads) while maintaining consistent performance over extended operational lifespans.

The fundamental premise of a linear sliding bearing is to provide a low-friction interface for linear motion while supporting the applied load and maintaining positional stability. Unlike rolling linear bearings, linear sliding bearings have no rolling elements, resulting in a simpler design, lower cost, and higher resistance to contamination (due to their solid contact surface). They are particularly well-suited for applications where high precision is not the primary requirement, or where the operating environment is prone to dust, debris, or moisture—conditions that can damage the rolling elements of ball/roller bearings. When paired with a compatible linear shaft or guide rail, the linear sliding bearing forms a complete linear motion system that is widely used across industries to replace less efficient sliding mechanisms (e.g., unlined bushings, metal-on-metal contact).

2. Core Structure of Linear Sliding Bearings

Linear sliding bearings have a relatively simple structure compared to rolling linear bearings, but their design is optimized to minimize friction, support loads, and ensure durability. While variations exist across different types of linear sliding bearings, the core structure remains consistent, consisting of the following key components:

2.1 Bearing Housing (Outer Sleeve)

The bearing housing—also known as the outer sleeve or outer race—is the outer structure of the linear sliding bearing and serves as the mounting point for the load. It is typically manufactured from high-strength materials such as carbon steel, stainless steel, aluminum alloy (for lightweight applications), or engineering plastics (for corrosion-resistant or low-noise applications). The housing is precision-machined to ensure tight tolerances, with an inner bore (cavity) designed to fit the linear shaft or rail. The outer surface of the housing often features mounting flats, threaded holes, or flanges to facilitate easy installation onto the moving load (e.g., machine tables, robotic arms, conveyor components).

2.2 Sliding Layer (Inner Liner)

The sliding layer—also referred to as the inner liner or bearing surface—is the most critical component of a linear sliding bearing, responsible for minimizing friction between the bearing and the shaft/rail. It is the part of the bearing that comes into direct contact with the fixed shaft or rail, and its material and design directly impact the bearing’s friction coefficient, wear resistance, and load capacity. Common materials used for sliding layers include: low-friction plastics (e.g., PTFE, POM, PA66), self-lubricating composites (e.g., PTFE mixed with graphite or bronze particles), porous bronze (impregnated with lubricant), and babbitt metal (for high-load applications). Some linear sliding bearings have a thin coating (e.g., DLC, TiN) on the sliding layer to further reduce friction and improve wear resistance.

2.3 Retaining Structure (If Applicable)

In some linear sliding bearings (e.g., split-type or composite bearings), a retaining structure is used to hold the sliding layer in place within the housing. This structure—often made from metal or rigid plastic—prevents the sliding layer from deforming or separating from the housing under load. For example, in porous bronze bearings, the bronze matrix acts as both the retaining structure and the sliding layer (when impregnated with lubricant). In plastic-lined bearings, the retaining structure may be a metal sleeve that supports the plastic liner, enhancing the bearing’s rigidity.

2.4 Seals and Wipers (Optional)

Many linear sliding bearings are equipped with optional seals or wipers, mounted on the ends of the housing, to prevent dust, debris, moisture, and other contaminants from entering the bearing’s inner bore. Seals also help retain lubricant within the bearing, reducing the need for frequent maintenance. Common seal types include lip seals, scraper seals, and felt wipers—each selected based on the severity of the operating environment. In clean environments, seals may be omitted to reduce friction and cost.

2.5 Lubrication Ports (Optional)

Some linear sliding bearings feature lubrication ports (located on the housing) to facilitate the application of lubricant (grease or oil). While self-lubricating bearings (e.g., PTFE-lined or porous bronze) do not require manual lubrication, lubricated bearings benefit from periodic lubrication to further reduce friction and wear. The lubrication port allows for easy access to the sliding layer, enabling the application of lubricant without disassembling the bearing.

3. Core Working Principles of Linear Sliding Bearings

Linear sliding bearings operate on the principle of sliding friction, where the bearing’s inner sliding layer glides directly against the surface of a fixed linear shaft or rail. The key to their performance is minimizing the friction between these two contact surfaces, which is achieved through three primary mechanisms: low-friction materials, lubrication, and surface engineering. Unlike rolling linear bearings, which convert sliding friction to rolling friction, linear sliding bearings optimize sliding friction to achieve smooth, efficient motion.

3.1 Sliding Friction Optimization

The primary working principle of a linear sliding bearing is the optimization of sliding friction between the bearing’s sliding layer and the shaft/rail. Friction occurs when two surfaces move relative to each other, and it is influenced by the material properties of the surfaces, the applied load, the surface finish, and the presence of lubricant. Linear sliding bearings minimize friction by using sliding layers made from materials with inherently low coefficients of friction (e.g., PTFE, which has a coefficient of friction as low as 0.04). Additionally, the sliding layer and shaft/rail are precision-machined to achieve a smooth surface finish, reducing the contact area between the two surfaces and further lowering friction.

When a load is applied to the bearing housing, the sliding layer distributes the load evenly across the contact surface with the shaft/rail. As the housing moves linearly along the shaft/rail, the sliding layer glides smoothly, with minimal friction and wear. The load-carrying capacity of the bearing depends on the area of the contact surface, the material strength of the sliding layer, and the friction coefficient—larger contact areas and stronger materials enable higher load capacities.

3.2 Lubrication-Assisted Sliding (Lubricated Bearings)

Many linear sliding bearings rely on lubrication to further reduce friction and wear. Lubricant (grease or oil) is applied between the sliding layer and the shaft/rail, forming a thin film that separates the two surfaces. This film eliminates direct metal-to-metal (or plastic-to-metal) contact, reducing friction to very low levels and preventing premature wear. The lubricant also acts as a coolant, dissipating heat generated by friction, and as a protective barrier against corrosion.

Lubricated linear sliding bearings are commonly used in high-load, high-speed applications where self-lubricating materials may not provide sufficient wear resistance. The frequency of lubrication depends on the operating speed, load, and environmental conditions—high-speed or heavy-load applications require more frequent lubrication to maintain the lubricant film.

3.3 Self-Lubricating Sliding (Self-Lubricating Bearings)

Self-lubricating linear sliding bearings eliminate the need for manual lubrication by incorporating lubricant into the sliding layer itself. This is achieved through two primary methods: porous materials (e.g., porous bronze) that are impregnated with lubricant, or composite materials (e.g., PTFE mixed with graphite, molybdenum disulfide, or bronze particles) that have inherent lubricating properties. As the bearing moves, the lubricant is gradually released from the sliding layer onto the contact surface, forming a thin lubricating film that minimizes friction and wear.

Self-lubricating linear sliding bearings are ideal for applications where manual lubrication is difficult (e.g., hard-to-reach components), or where lubricant contamination is a concern (e.g., food processing, medical devices). They also reduce maintenance requirements and downtime, making them suitable for high-volume industrial applications.

4. Common Types of Linear Sliding Bearings: Classification and Key Features

Linear sliding bearings are classified based on their design, sliding layer material, lubrication method, and application. Below are the most widely used types, along with their unique characteristics, advantages, and limitations:

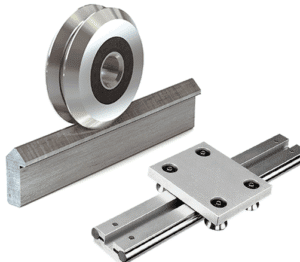

4.1 Plain Linear Bushings (Cylindrical Sliding Bearings)

Plain linear bushings—also known as cylindrical linear sliding bearings—are the most common type, designed to fit around a cylindrical linear shaft. They have a simple cylindrical design, with a housing and an inner sliding layer that glides along the shaft. Plain linear bushings are available in two main variants: solid bushings (one-piece design) and split bushings (two-piece design, for easy installation without removing the shaft).

Key features: Simple design, low cost, and easy installation. They are available in a wide range of sizes, from small miniature bushings (for precision instruments) to large industrial bushings (for heavy machinery). Plain linear bushings are suitable for light to moderate radial loads and low to moderate speeds. They can be lubricated or self-lubricating, depending on the application. Solid bushings offer higher rigidity, while split bushings provide convenience for maintenance and replacement.

Limitations: Limited to radial loads (cannot withstand significant axial or moment loads). They have higher friction than rolling linear bearings, making them unsuitable for high-speed applications. They also require precise alignment between the bushing and shaft to avoid uneven wear.

4.2 Porous Bronze Linear Bearings

Porous bronze linear bearings are a type of self-lubricating linear sliding bearing, made from porous bronze alloy (e.g., CuSn10, CuPb10Sn10) that is impregnated with lubricating oil. The porous structure of the bronze allows the oil to be stored within the material, and as the bearing moves, the oil is released onto the contact surface through capillary action, forming a lubricating film.

wang, tingting