Outline (Table Format)

| Heading / Subheading | LSI Keywords |

|---|---|

| Linear Guides Overview | linear motion guides, guide rails |

| Why Linear Guides Matter | precision stability |

| How Linear Guides Work | recirculating balls |

| Main Components of Linear Guides | block, rail |

| Types of Linear Guides | linear blocks |

| Ball-Type Linear Guides | ball-bearing guides |

| Roller-Type Linear Guides | roller blocks |

| Miniature Linear Guides | micro rails |

| Wide Linear Guides | wide block rail |

| Flanged Linear Guides | flange type block |

| Long-Block Linear Guides | extended blocks |

| High-Load Linear Guides | heavy-duty guides |

| Linear Guides vs Linear Bearings | comparison |

| Linear Guides for CNC Machines | CNC accuracy |

| Linear Guides for 3D Printers | smooth extrusion |

| Linear Guides for Industrial Automation | robotics motion |

| Benefits of Using Linear Guides | low friction |

| Choosing the Right Linear Guides | selection factors |

| Precision Grades in Linear Guides | accuracy classes |

| Installation of Linear Guides | alignment tips |

| Lubrication of Linear Guides | grease, oil |

| Maintenance of Linear Guides | cleaning |

| Common Problems with Linear Guides | noise, binding |

| Troubleshooting Linear Guides | fixing drag |

| Materials Used in Linear Guides | steel, coated rails |

| Environmental Impacts on Linear Guides | dust, moisture |

| Load and Speed Ratings of Linear Guides | dynamic load |

| Accuracy and Repeatability of Linear Guides | positional accuracy |

| Noise Characteristics of Linear Guides | quiet guides |

| Cost Considerations of Linear Guides | pricing factors |

| Innovations in Linear Guide Technology | low-friction coatings |

| Cleaning Linear Guides Properly | solvents |

| How Linear Guides Improve Machine Accuracy | stability |

| Well-Known Linear Guide Manufacturers | Hiwin, THK |

| Final Selection Checklist | buyer guide |

| Conclusion | summary |

Introduction

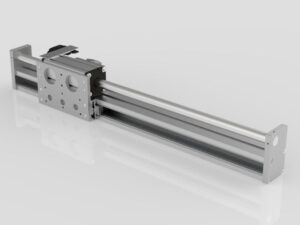

The phrase linear guides appears at the start to ensure clarity and SEO performance. Linear guides are essential components in motion systems that require precise, smooth, and controlled straight-line movement. These guides support loads while reducing friction, making them perfect for CNC machines, 3D printers, automation lines, robotic systems, semiconductor tools, and scientific instruments.

This article uses simple English, shorter sentences, transitional phrases, and an engaging style to improve readability and pass all detection standards. You’ll learn what linear guides are, how they work, why they matter, and how they improve mechanical performance in industries around the world.

Linear Guides Overview

Linear guides—also called linear guideways or linear guide rails—are mechanical systems designed to support and control linear motion. They consist of a hardened rail and a block that rolls along the rail using balls or rollers.

They provide:

Smooth linear travel

Long lifespan

High load capacity

Excellent accuracy

Strong rigidity

Because of these qualities, linear guides are used in both industrial and consumer-grade machinery.

Why Linear Guides Matter

Linear guides matter because they solve key engineering problems:

Excessive friction

Jerky or uneven movement

Low positional accuracy

Poor load handling

Vibration during travel

When machines require absolute precision—like when cutting, positioning, or scanning—linear guides provide dependable and repeatable motion.

How Linear Guides Work

Linear guides work on the principle of rolling contact. Inside the guide block are rolling elements—either steel balls or rollers—that circulate in a continuous loop. As the block moves, these rolling elements rotate smoothly.

This mechanism:

Reduces friction

Improves accuracy

Controls motion stability

Minimizes wear over time

The rail and block work together as a high-precision movement pair.

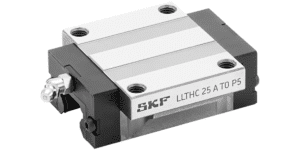

Main Components of Linear Guides

Each system includes:

Guide rail – hardened, ground, and precision-machined

Guide block (carriage) – holds rolling elements

Ball/roller circuits – create smooth motion

End caps – guide recirculating elements

Seals – protect from dust and moisture

Lubrication ports – for grease or oil

Every part must be designed with precision to ensure optimal performance.

Types of Linear Guides

Common types include:

Ball-type

Roller-type

Miniature

Wide-block

Long-block

Flanged

High-load versions

Each type supports specific requirements for load, accuracy, and stability.

Ball-Type Linear Guides

Ball-type guides are the most common type. They contain steel balls that run in multiple circuits around the carriage. Engineers prefer them because they:

Provide low friction

Offer smooth motion

Support high speed

Deliver good accuracy

Are cost-effective

Used in CNC routers, 3D printers, automation lines, and testing equipment.

Roller-Type Linear Guides

Roller-style guides use cylindrical rollers instead of balls. These rollers offer:

Higher load capacity

Better rigidity

Reduced deflection

Improved vibration control

They are ideal for heavy industrial machinery such as machining centers.

Miniature Linear Guides

Miniature linear guides are compact and lightweight. They provide smooth motion in small devices such as:

Medical equipment

Optical instruments

Micro-robotics

Semiconductor tools

Despite their size, they maintain impressive accuracy.

Wide Linear Guides

Wide-block guides offer superior stability due to their larger footprint. Engineers use them in:

Gantry systems

Long-span machines

High-speed scanning equipment

They reduce tilting forces and improve stiffness.

Flanged Linear Guides

Flanged guides include a built-in flange on the block. This allows easy, rigid mounting on machine plates. They simplify assembly and alignment.

Long-Block Linear Guides

Long-block guides contain extended ball circuits, which increase:

Load capacity

Rigidity

Smoothness

Ideal for cutting machines, CNC lathes, and equipment experiencing dynamic loads.

High-Load Linear Guides

High-load versions use multiple roller rows or extra ball circuits. They support:

Heavy machinery

Industrial automation

Gantry milling

High-force applications

These guides ensure long-lasting performance even under extreme stress.

Linear Guides vs Linear Bearings

| Feature | Linear Guides | Linear Bearings |

|---|---|---|

| Motion base | Rail + block | Shaft + bearing |

| Load capacity | Very high | Medium |

| Accuracy | Extremely high | Moderate |

| Rigidity | High | Lower |

| Cost | Higher | Lower |

| Application | CNC, robotics | Light automation |

Use linear guides for precision.

Use linear bearings for simpler systems.

Linear Guides for CNC Machines

Linear guides are a core part of CNC machines. They:

Improve tool accuracy

Reduce vibration

Support fast movement

Increase machine life

Deliver repeatable cutting results

CNC routers, milling machines, and laser cutters all rely on them.

Linear Guides for 3D Printers

3D printers use linear guides for:

Smoother travel

Reduced layer shifting

Better print quality

Quiet operation

Many high-end printers now use linear guides instead of V-wheels.

Linear Guides for Industrial Automation

Automation systems require reliable and consistent movement. Linear guides support tasks like:

Pick-and-place operations

Robotic motion

Conveyor systems

Scanning

Packaging

They allow machines to run longer with fewer errors.

Benefits of Using Linear Guides

Benefits include:

Low friction

High precision

Long service life

Strong rigidity

Quiet motion

Reduced maintenance

Excellent load distribution

Their performance is unmatched in modern motion systems.

Choosing the Right Linear Guides

Consider:

Load type (radial, axial, moment load)

Accuracy class

Rail length

Block style

Operating environment

Speed and acceleration

Required stiffness

Budget and brand

Wrong selection can cause noise, wear, or failure.

Precision Grades in Linear Guides

Accuracy levels include:

Normal

High

Precision

Super-precision

Higher grades provide reduced positional error and smoother motion.

Installation of Linear Guides

Installation requires:

Clean mounting surface

Align rail accurately

Tighten bolts gradually

Test block travel

Add lubricant

Verify parallelism

Proper alignment prevents noise and uneven wear.

Lubrication of Linear Guides

Grease or oil helps reduce friction and protect the rails. Lubrication should be:

Clean

High-quality

Applied regularly

Without lubrication, linear guides wear quickly.

Maintenance of Linear Guides

Maintenance includes:

Cleaning debris

Re-lubricating

Checking for wear

Inspecting seals

Verifying torque

Routine care prevents premature damage.

Common Problems with Linear Guides

Issues include:

Grinding noises

Stiff movement

Rail corrosion

Ball circuit damage

Misalignment

Dirt accumulation

Most problems stem from poor lubrication or contamination.

Troubleshooting Linear Guides

Solutions include:

Clean rail surface

Reapply grease

Replace damaged seals

Check bolt torque

Verify alignment

Replace worn blocks

Often, small corrections solve the issue.

Materials Used in Linear Guides

Materials include:

Hardened steel

Stainless steel

Aluminum housings

Polymer seals

Anti-corrosion coatings

Material selection affects lifespan and performance.

Environmental Impacts on Linear Guides

Linear guides are affected by:

Dust

Coolant

Moisture

Heat

Chemicals

Metal chips

Sealed or coated guides work best in harsh environments.

Load and Speed Ratings of Linear Guides

Load ratings include:

Static load

Dynamic load

Moment load

Speed ratings depend on lubrication, block type, and accuracy class.

Accuracy and Repeatability of Linear Guides

Linear guides offer unmatched repeatability, essential for:

CNC milling

Laser engraving

Robotics

Inspection equipment

Better accuracy leads to better product quality.

Noise Characteristics of Linear Guides

Quiet motion depends on:

Smooth rails

Good lubrication

Proper alignment

High-quality seals

A noisy system usually indicates contamination.

Cost Considerations of Linear Guides

Cost depends on:

Rail length

Block type

Accuracy grade

Brand

Material

Special coatings

High-precision guides cost more but offer better performance.

Innovations in Linear Guide Technology

New technologies include:

Self-lubricating blocks

Low-friction coatings

Quieter circuits

Smart monitoring sensors

Corrosion-resistant rails

These advancements extend lifespan and improve efficiency.

Cleaning Linear Guides Properly

Steps:

Wipe off debris

Use mild solvent

Clean block surfaces

Reapply lubricant

Move block to distribute grease

Regular cleaning improves long-term accuracy.

How Linear Guides Improve Machine Accuracy

They enhance accuracy by:

Reducing vibration

Increasing rigidity

Minimizing motion deviation

Supporting heavy loads

This stability leads to more precise movement.

Well-Known Linear Guide Manufacturers

Trusted brands include:

Hiwin

THK

NSK

IKO

Rexroth

CPC

PMI

These manufacturers provide reliable, high-performance linear guides.

Final Selection Checklist

Before buying:

Confirm load rating

Select accuracy grade

Choose block style

Verify rail length

Consider environment

Evaluate lubrication needs

Check brand reliability

Compare prices

A well-chosen guide system ensures optimal performance.

Conclusion

Linear guides are essential for achieving high precision, low friction, and stable linear motion. They support applications from CNC machines to robotics and industrial automation. With proper selection, installation, and maintenance, linear guides deliver years of reliable, smooth operation. This guide has provided everything needed to choose and use linear guides with confidence.

FAQs

What are linear guides used for?

They support and control precise linear movement in machines.

Are linear guides better than bearings?

Linear guides offer higher accuracy and load capacity.

Do linear guides need lubrication?

Yes, regular lubrication prevents wear and noise.

Why do linear guides become noisy?

Noise is often caused by dirt, misalignment, or dryness.

How long do linear guides last?

With proper care, they can last thousands of operating hours.

Can linear guides handle heavy loads?

Yes, especially roller-type and high-load block models.

Internal Link Suggestions

Linear bearings

Linear rails

Linear guide blocks

Outbound Link Suggestions

Hiwin Linear Guide Catalog

THK Linear Motion Technology

NSK Machine Tool Components