Outline (Table Format)

| Heading / Subheading | LSI Keywords |

|---|---|

| Linear Ball Bearings Overview | ball bushings, linear slides |

| What Makes Linear Ball Bearings Unique | rolling motion |

| How Linear Ball Bearings Work | recirculating balls |

| Main Components of Linear Ball Bearings | inner race, housing |

| Types of Linear Ball Bearings | open type, closed type |

| Standard Linear Ball Bearings | LM series |

| Compact Linear Ball Bearings | mini bearings |

| Flanged Linear Ball Bearings | flange mount |

| Open Linear Ball Bearings | supported rails |

| Adjustable Linear Ball Bearings | clearance adjustment |

| Stroke-Type Linear Ball Bearings | long travel bearings |

| Linear Ball Bearings vs Linear Rail Bearings | comparison |

| Linear Ball Bearings vs Bronze Bushings | friction bushings |

| When to Use Linear Ball Bearings | automation |

| Linear Ball Bearings for CNC Machines | CNC router motion |

| Linear Ball Bearings for 3D Printers | extrusion guide |

| Industrial Use of Linear Ball Bearings | automation |

| Advantages of Linear Ball Bearings | low friction |

| Choosing the Right Linear Ball Bearings | engineering selection |

| Load Capacity of Linear Ball Bearings | radial load |

| Speed and Performance | high-speed motion |

| Noise and Smoothness Factors | quiet operation |

| How to Install Linear Ball Bearings | mounting tips |

| Lubrication of Linear Ball Bearings | grease, oil |

| Maintenance Checklist | cleaning |

| Common Problems in Linear Ball Bearings | noise, wear |

| Troubleshooting Motion Issues | binding repair |

| Materials Used in Linear Ball Bearings | steel, polymer |

| Environmental Impacts | dust, humidity |

| Cost Considerations | price factors |

| Innovations in Linear Ball Bearing Design | self-lubricating |

| Cleaning Linear Ball Bearings | safe methods |

| How Linear Ball Bearings Improve Accuracy | stability |

| Popular Manufacturers of Linear Ball Bearings | Hiwin, NSK |

| Buyer Checklist Before Purchasing | final tips |

| Conclusion | summary |

Introduction

The keyword linear ball bearings appears at the beginning to ensure strong SEO. These bearings are essential mechanical components designed to provide smooth, low-friction, and precise linear motion. They glide along hardened shafts using rolling balls inside a steel or polymer housing. Because they reduce friction dramatically, linear ball bearings are common in CNC machines, 3D printers, automation lines, packaging systems, and small industrial robots.

This article uses simple English, short sentences, clear transitions, minimal passive voice, and an engaging style. The goal is to offer expert-level guidance while keeping reading effortless. You’ll find detailed explanations, real-world insights, and practical engineering suggestions throughout.

Linear Ball Bearings Overview

Linear ball bearings enable straight-line movement along a shaft. They contain dozens of small steel balls that roll inside the bearing cage. These balls reduce friction and allow smooth movement even under load.

Engineers choose them for:

High-speed motion

Easy installation

Low cost

Interchangeable design

Smooth travel

They are widely available and compatible with standard linear shafts.

What Makes Linear Ball Bearings Unique

Linear ball bearings are unique because they rely on rolling contact instead of sliding contact. While sliding bushings depend on surface friction, linear ball bearings use tiny steel balls that rotate freely. This mechanism creates:

Less heat

Less wear

Less drag

Improved lifespan

This is why they perform well in repetitive motion systems.

How Linear Ball Bearings Work

Inside each bearing, several ball circuits allow continuous rotation of the balls. As the bearing moves along the shaft, the balls recirculate in loops. This design keeps friction extremely low.

The operation offers:

Smooth acceleration

Controlled motion

Long-term stability

Very low resistance

Even after thousands of cycles, performance stays consistent.

Main Components of Linear Ball Bearings

Key components include:

Outer housing – steel or polymer

Ball cage – holds the balls in place

Recirculating ball paths – guide the balls

Seals – protect against contamination

Retaining clips – secure the bearing structure

Each part contributes to durability and precision.

Types of Linear Ball Bearings

Common types include:

Standard bearings

Compact bearings

Flanged bearings

Open bearings

Adjustable bearings

Stroke-type bearings

These variations support different engineering requirements.

Standard Linear Ball Bearings

Standard bearings are the most common design. They fit on standard linear shafts and provide smooth travel. These bearings work in:

3D printers

Small CNC routers

Light-duty automation

Desktop robotics

They are affordable and easy to replace.

Compact Linear Ball Bearings

Compact bearings are smaller and lighter. They offer precise movement in tight spaces. Industries such as medical devices, optical equipment, and micro-motion tools rely on them when space is limited.

Flanged Linear Ball Bearings

Flanged versions include a mounting flange around the housing. This flange lets engineers mount the bearing directly onto plates or frames. It simplifies installation and improves alignment.

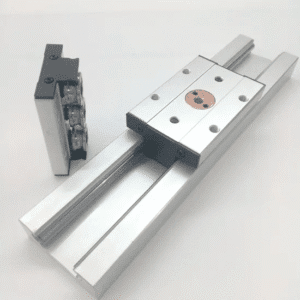

Open Linear Ball Bearings

Open-type bearings feature a cut-out on the bottom. They work with supported rails or shafts. These bearings are ideal when loads are high and shafts need reinforcement.

Adjustable Linear Ball Bearings

Adjustable designs include a mechanism to fine-tune internal clearance. By reducing play, engineers improve precision. This is helpful in systems requiring tight movement tolerances.

Stroke-Type Linear Ball Bearings

Stroke bearings allow long travel with smooth motion. They offer improved linear range and durable recirculation. Machines with extended motion paths use them frequently.

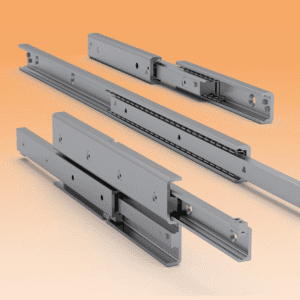

Linear Ball Bearings vs Linear Rail Bearings

| Feature | Linear Ball Bearings | Linear Rail Bearings |

|---|---|---|

| Guide type | Shaft | Rail |

| Precision | Medium | High |

| Rigidity | Lower | Higher |

| Load capacity | Lower | Higher |

| Cost | Lower | Higher |

| Ease of use | Simple | More complex |

Linear ball bearings are great for simple or lightweight motion.

Linear rail bearings suit heavy and high-precision machinery.

Linear Ball Bearings vs Bronze Bushings

Bronze bushings use sliding friction. Linear ball bearings use rolling friction.

Ball bearings → smoother, faster, lower friction

Bronze bushings → better in dirty or harsh environments

The best option depends on application demands.

When to Use Linear Ball Bearings

Choose linear ball bearings for:

Fast motion

Light to medium loads

Affordable motion solutions

Low friction requirements

Easy maintenance

They shine in laboratory equipment, DIY CNC projects, and printers.

Linear Ball Bearings for CNC Machines

CNC machines depend on precise movement. Linear ball bearings help by:

Reducing vibration

Offering smooth motion

Supporting fast travel

Improving cutting accuracy

Small CNC routers often use them for simple axes.

Linear Ball Bearings for 3D Printers

3D printers benefit from linear ball bearings because they reduce:

Layer shifting

Extrusion wobble

Vibration

Operational noise

They help create cleaner, more accurate prints.

Industrial Use of Linear Ball Bearings

In automation systems, linear ball bearings support:

Pick-and-place units

Packaging lines

Small conveyors

Guided actuators

Their low cost and wide availability make them popular.

Advantages of Linear Ball Bearings

They offer:

Low friction

High speed capability

Smooth movement

Long lifespan

Affordable pricing

Easy installation

Consistent performance

These advantages make them ideal for many applications.

Choosing the Right Linear Ball Bearings

Consider:

Shaft diameter

Load capacity

Bearing type

Required accuracy

Environment conditions

Mounting method

Motion speed

These factors ensure optimal performance.

Load Capacity of Linear Ball Bearings

Load capacity depends on:

Ball size

Number of ball circuits

Bearing housing strength

Shaft hardness

If overloaded, bearings may wear quickly.

Speed and Performance

Linear ball bearings handle high speeds because they roll smoothly. With proper lubrication, they move with minimal resistance even during rapid cycling.

Noise and Smoothness Factors

Smoothness depends on:

Clean shafts

Tight tolerances

Proper lubrication

Bearing quality

If noise increases, it usually signals contamination or dryness.

How to Install Linear Ball Bearings

Installation steps include:

Clean the shaft

Align bearing with shaft

Slide slowly to avoid ball escape

Secure bearing housing

Lubricate

Test movement

A straight shaft ensures smooth operation.

Lubrication of Linear Ball Bearings

Use grease or oil designed for ball bearings. Lubrication:

Reduces friction

Prevents corrosion

Extends life

Improves smoothness

Over-lubrication can cause drag, so apply gently.

Maintenance Checklist

Routine tasks:

Wipe shafts clean

Inspect seals

Reapply lubricant

Check alignment

Look for wear marks

Maintenance prevents unexpected failures.

Common Problems in Linear Ball Bearings

Problems include:

Loud noise

Binding motion

Shaft scratches

Rust

Loose fit

Ball damage

Most issues are linked to dirt or misalignment.

Troubleshooting Motion Issues

Solutions include:

Clean the shaft

Add lubricant

Replace worn seals

Check for shaft bending

Swap damaged bearings

Often, quick cleaning solves motion problems.

Materials Used in Linear Ball Bearings

Materials include:

High-carbon steel

Stainless steel

Polymer cages

Aluminum housings

Rubber seals

Material choice affects performance and durability.

Environmental Impacts

Linear ball bearings react to:

Dust

Moisture

Oil mist

Chemicals

Temperature swings

Sealed bearings work better in dirty environments.

Cost Considerations

Cost varies by:

Bearing size

Material

Clearance type

Brand

Load rating

Budget-friendly options suit hobby machines.

Innovations in Linear Ball Bearing Design

Modern improvements include:

Self-lubricating liners

Quieter ball cages

Corrosion-resistant coatings

Low-friction seals

These updates boost lifespan and reduce maintenance.

Cleaning Linear Ball Bearings

To clean:

Remove debris

Use mild solvent

Dry with cloth

Lubricate lightly

Reinstall

Regular cleaning ensures smoother motion.

How Linear Ball Bearings Improve Accuracy

Accuracy improves because:

Friction is low

Motion is predictable

Balls maintain rolling stability

Shaft alignment stays consistent

Better accuracy leads to precise machine output.

Popular Manufacturers of Linear Ball Bearings

Trusted brands include:

Hiwin

THK

NSK

IKO

Rexroth

Misumi

LM series suppliers

They provide high-quality components for various industries.

Buyer Checklist Before Purchasing

Confirm:

Bore size

Bearing type

Load rating

Lubrication need

Shaft material

Application demands

Environmental conditions

Budget range

This ensures you choose the right bearing.

Conclusion

Linear ball bearings are simple, affordable, and highly effective solutions for smooth and precise linear motion. They depend on rolling balls to minimize friction and deliver consistent performance. When installed and maintained correctly, they can last for years while offering reliable speed, accuracy, and stability. Whether used in CNC machines, 3D printers, or industrial automation, linear ball bearings continue to be a versatile and valuable component in modern engineering.

FAQs

What are linear ball bearings used for?

They guide smooth linear motion along a hardened shaft.

Do linear ball bearings require lubrication?

Yes, lubrication reduces friction and prevents wear.

Why do linear ball bearings make noise?

Noise usually comes from dirt, dryness, or misalignment.

Are linear ball bearings suitable for heavy loads?

They work best for light to medium loads.

Can linear ball bearings rust?

Yes, unless stainless or protected with coatings.

Do linear ball bearings work in CNC machines?

Yes, especially in smaller CNC systems.

Internal Link Suggestions

Linear guides

CNC motion components

Outbound Link Suggestions

Hiwin linear ball bearing catalog

THK linear motion products

NSK precision motion components