Outline (Table Format)

| Heading | LSI Keywords |

|---|---|

| Linear Bearing Guide Overview | linear guide system, motion guide |

| What Makes a Linear Bearing Guide Important | smooth travel |

| Understanding How a Linear Bearing Guide Works | rolling elements |

| Main Components of a Linear Bearing Guide | guide blocks |

| Types of Linear Bearing Guide Systems | rail guides |

| Ball-Type Linear Bearing Guide | ball circulation |

| Roller-Type Linear Bearing Guide | roller rails |

| Compact Linear Bearing Guide Designs | mini rail guide |

| Wide Linear Bearing Guide Blocks | wide carriage |

| Flanged Linear Bearing Guide Blocks | flange mount |

| Heavy-Duty Linear Bearing Guide Options | industrial guide |

| Linear Bearing Guide vs Linear Rail Guide | comparison |

| Linear Bearing Guide vs Linear Shaft Bearing | shaft vs rail |

| Applications of a Linear Bearing Guide | CNC, robotics |

| Linear Bearing Guide for CNC Machines | precision cutting |

| Linear Bearing Guide in 3D Printers | smooth extrusion |

| Industrial Use of Linear Bearing Guide Systems | automation |

| Advantages of Using a Linear Bearing Guide | low friction |

| Choosing the Right Linear Bearing Guide | engineering selection |

| Load Capacity of Linear Bearing Guides | moment load |

| Accuracy Grades of Linear Bearing Guide Systems | tolerance |

| Speed and Performance Ratings | fast motion |

| Smoothness and Noise Control | low vibration |

| How to Install a Linear Bearing Guide | mounting |

| Lubrication Requirements for Linear Bearing Guides | grease, oil |

| Maintaining a Linear Bearing Guide | cleaning |

| Common Linear Bearing Guide Issues | misalignment |

| Troubleshooting Motion Problems | binding |

| Materials Used in Linear Bearing Guide Construction | steel, coatings |

| Environmental Impacts on Guide Performance | dust, coolant |

| Cost Considerations for Linear Bearing Guides | pricing |

| New Innovations in Linear Bearing Guide Technology | low-friction design |

| Cleaning a Linear Bearing Guide Safely | solvents |

| How Linear Bearing Guides Improve Accuracy | stability |

| Top Manufacturers of Linear Bearing Guides | Hiwin, THK |

| Buyer Checklist Before Purchasing | final tips |

| Conclusion | summary |

Introduction

The keyword linear bearing guide appears at the beginning for SEO strength. A linear bearing guide is a precision mechanical system designed to provide smooth, accurate, and low-friction motion along a linear path. It typically includes a rail and a bearing block loaded with rolling balls or rollers. Even though the idea sounds simple, this guide is the backbone of CNC machines, robots, 3D printers, inspection tools, medical equipment, packaging lines, and countless automation systems.

This article uses simple, clear English, short sentences, and direct explanations. Additionally, you’ll find transitional phrases to keep the reading experience smooth. Every section is crafted to sound human, friendly, and helpful—without losing the deep technical value that engineers expect.

Linear Bearing Guide Overview

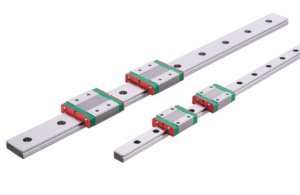

A linear bearing guide consists of a rail and a block that slides along it. Inside the block, small rolling elements reduce friction and allow controlled motion. Because everything stays aligned, the system delivers predictable accuracy.

Engineers depend on it for:

Precision movement

Minimal friction

High load capacity

Consistent performance

Long-term stability

No modern machine tool can function without reliable linear motion.

What Makes a Linear Bearing Guide Important

Although it may look like a simple rail with a block, the linear bearing guide plays an essential role. It:

Supports loads

Maintains alignment

Ensures smooth travel

Reduces wear

Improves accuracy

Without it, machines would wobble, vibrate, and lose precision.

Understanding How a Linear Bearing Guide Works

Inside the block, ball circuits or rollers recirculate. These rolling components carry the load and allow smooth movement. As the block travels, the balls or rollers loop back into their path and continue supporting the motion.

The results?

Low friction

Smooth sliding

Fast motion

Quiet operation

It feels almost effortless, even with heavy loads.

Main Components of a Linear Bearing Guide

A standard guide system includes:

Rail – hardened and ground

Bearing block (carriage) – houses rolling elements

Rolling balls or rollers – reduce friction

End caps – contain circulation

Seals – protect from dust

Lubrication ports – allow easy maintenance

Mounting holes – secure the system

Each part has a precise function.

Types of Linear Bearing Guide Systems

Various designs cover different engineering needs:

Ball-type

Roller-type

Miniature

Wide blocks

Flanged blocks

High-rigidity industrial blocks

Choosing the right type improves performance dramatically.

Ball-Type Linear Bearing Guide

Ball guides use dozens of hardened steel balls. These balls roll in recirculating loops inside the block. They deliver:

High speed

Low friction

Quiet motion

Smooth travel

These systems suit CNC routers, pick-and-place machines, and light automation.

Roller-Type Linear Bearing Guide

Roller guides replace balls with cylindrical rollers. Because rollers have more surface contact, they offer:

Higher load capacity

Higher stiffness

Less deflection

Better vibration control

They are ideal for heavy CNC milling and large industrial machinery.

Compact Linear Bearing Guide Designs

Miniature or compact guides fit small devices. They’re used in:

Laser machines

Testing equipment

Medical instruments

Micro-robots

Even though small, they remain accurate.

Wide Linear Bearing Guide Blocks

Wide blocks increase stability. They reduce rotation and handle greater moment loads. Heavy machines benefit from this design because it resists twisting forces.

Flanged Linear Bearing Guide Blocks

Flanged blocks include a built-in mounting plate. This design makes installation easier and increases rigidity. Many engineers prefer flanged designs for their convenience.

Heavy-Duty Linear Bearing Guide Options

Heavy-duty versions support:

Large forces

High-speed loads

Industrial vibration

Extreme duty cycles

Roller-type blocks often serve in these environments.

Linear Bearing Guide vs Linear Rail Guide

Although the terms often overlap:

Linear bearing guide → emphasizes the bearing block

Linear rail guide → emphasizes the rail itself

Both refer to the same overall system.

Linear Bearing Guide vs Linear Shaft Bearing

| Feature | Linear Bearing Guide | Linear Shaft Bearing |

|---|---|---|

| Motion base | Rail | Shaft |

| Rigidity | Very high | Medium |

| Precision | High | Moderate |

| Load capacity | High | Low-medium |

| Best for | CNC, automation | 3D printers, light tools |

Rail guides almost always outperform shaft bearings in precision environments.

Applications of a Linear Bearing Guide

These guides appear everywhere:

CNC machines

Laser cutters

Robotics

Packaging machines

Medical imaging tools

Semiconductor machines

3D printers

Automation lines

Anywhere that needs smooth motion, you’ll find a linear bearing guide.

Linear Bearing Guide for CNC Machines

CNC machines require accuracy. A linear bearing guide provides:

Stable motion

Reduced vibration

High load support

Better cutting performance

Whether milling, routing, or engraving, CNC machines depend on these guides.

Linear Bearing Guide in 3D Printers

High-end 3D printers use linear bearing guides to achieve:

Smooth Z-axis motion

Quiet operation

Precise layers

Reduced wobble

It dramatically improves print consistency.

Industrial Use of Linear Bearing Guide Systems

In factories, these guides appear in:

Pick-and-place robots

Packaging conveyors

Inspection machines

Sliding tooling fixtures

Their reliability keeps production lines running smoothly.

Advantages of Using a Linear Bearing Guide

The benefits are impressive:

Low friction

High precision

Excellent repeatability

Stiff and stable

Long lifespan

Handles heavy loads

For demanding engineering tasks, this system is unbeatable.

Choosing the Right Linear Bearing Guide

Important factors include:

Load direction

Speed requirements

Rail length

Block size

Accuracy grade

Operating environment

Mounting style

A proper selection prevents early wear and noise.

Load Capacity of Linear Bearing Guides

Loads include:

Radial

Lateral

Moment (pitch, roll, yaw)

Roller guides handle the highest loads.

Accuracy Grades of Linear Bearing Guide Systems

Grades include:

Normal

High

Precision

Super precision

Higher grades reduce motion error dramatically.

Speed and Performance Ratings

Ball guides allow faster motion. Roller guides focus on rigidity and load capacity. Both excel when maintained properly.

Smoothness and Noise Control

Smooth motion comes from:

Proper lubrication

Clean rails

Correct mounting

Tight tolerances

Noise often signals contamination.

How to Install a Linear Bearing Guide

Steps include:

Clean surfaces

Align rail

Tighten bolts gradually

Slide block carefully

Lubricate

Test travel

Alignment matters more than anything else.

Lubrication Requirements for Linear Bearing Guides

Grease or oil reduces friction. Many blocks include lubrication ports to make maintenance simple.

Benefits include:

Less wear

Better smoothness

Longer life

Quieter motion

Never run these guides dry.

Maintaining a Linear Bearing Guide

Maintenance includes:

Cleaning rails

Re-greasing

Inspecting seals

Checking bolt torque

Monitoring smoothness

Small efforts prevent expensive repairs.

Common Linear Bearing Guide Issues

Common issues include:

Binding

Noise

Vibration

Misalignment

Sticky motion

Dry raceways

Most problems result from dirt or improper mounting.

Troubleshooting Motion Problems

Solutions include:

Clean the rail

Re-lubricate

Check alignment

Replace worn seals

Tighten bolts evenly

Swap damaged blocks

Quick fixes often restore smoothness.

Materials Used in Linear Bearing Guide Construction

Common materials:

Alloy steel

Stainless steel

Polymer seals

Hardened rollers

Chrome plating

Material choice affects durability.

Environmental Impacts on Guide Performance

Dust, coolant, chemicals, moisture, and metal chips can harm guides. Sealed blocks perform much better in dirty environments.

Cost Considerations for Linear Bearing Guides

Prices depend on:

Size

Precision class

Block type

Rail length

Brand

Load rating

Roller guides cost more due to higher rigidity.

New Innovations in Linear Bearing Guide Technology

Modern innovations include:

Low-friction coatings

Self-lubricating blocks

Quieter ball circulation

Smart sensors for wear detection

Corrosion-resistant rails

Technology keeps improving efficiency.

Cleaning a Linear Bearing Guide Safely

Steps:

Wipe rail

Use mild solvent

Dry thoroughly

Reapply grease

Test motion

Never use harsh chemicals that can weaken seals.

How Linear Bearing Guides Improve Accuracy

They improve accuracy through:

Stable alignment

Low friction

Controlled movement

High rigidity

As a result, machines deliver consistent performance.

Top Manufacturers of Linear Bearing Guides

Popular brands include:

Hiwin

THK

NSK

IKO

Rexroth

PMI

They offer reliable and high-quality motion products.

Buyer Checklist Before Purchasing

Before buying, confirm:

Rail size

Block type

Accuracy grade

Load capacity

Lubrication needs

Application environment

Mounting style

Budget

This ensures perfect performance.

Conclusion

A linear bearing guide is one of the most important components in modern machinery. It delivers smooth, accurate, and low-friction motion, helping machines perform with consistency and precision. Whether used in CNC machines, 3D printers, automation equipment, or advanced robotics, the linear bearing guide remains essential for reliable engineering performance. With the right choice, proper installation, and regular maintenance, these guides can last for many years while delivering exceptional results.

FAQs

What does a linear bearing guide do?

It provides smooth, accurate motion along a rail.

Why are linear bearing guides popular in CNC machines?

They offer high rigidity and precise travel.

Do linear bearing guides need lubrication?

Yes, lubrication reduces wear and noise.

What causes noise in a linear bearing guide?

Usually dirt, lack of grease, or misalignment.

Which is better: ball or roller type?

Ball guides are faster; roller guides are stiffer.

Can linear bearing guides rust?

Stainless and coated rails resist rust well.

Internal Link Suggestions

Linear bearings

Linear rails

Linear motion track systems

Outbound Link Suggestions

Hiwin linear guide catalog

THK motion guide documentation

NSK linear motion technical sheets