Outline (Table Format)

| Heading / Subheading | LSI Keywords |

|---|---|

| Linear Guide Overview | linear motion guide, guideway |

| Why Linear Guide Systems Matter | precision motion |

| How a Linear Guide Works | rolling elements |

| Core Components of a Linear Guide | rails, blocks |

| Types of Linear Guide Systems | ball guides, roller guides |

| Ball-Type Linear Guide | ball-bearing guideways |

| Roller-Type Linear Guide | heavy-load guides |

| Miniature Linear Guide Systems | compact linear guide |

| Heavy-Duty Linear Guides | industrial guideways |

| Linear Guides for CNC Machines | machining accuracy |

| Linear Guides in Robotics | robotic motion |

| Linear Guides in Automation Equipment | automated systems |

| Advantages of Using a Linear Guide | stability, low friction |

| Applications of Linear Guide Systems | packaging, manufacturing |

| How to Choose the Right Linear Guide | selection factors |

| Installation Guidelines for Linear Guides | alignment tips |

| Lubrication for Linear Guide Systems | maintenance oil |

| Maintenance Best Practices | cleaning, inspection |

| Common Problems With Linear Guides | noise, dust |

| Troubleshooting Guideway Issues | binding, uneven motion |

| Linear Guide vs Linear Bearing | comparison |

| Materials Used in Linear Guide Rails | stainless steel |

| Environmental Effects on Linear Guides | heat, moisture |

| Load Ratings and Performance | load capacity |

| Speed and Acceleration Features | high-speed guideways |

| Cost Factors for Linear Guides | price points |

| Innovations in Linear Guide Technology | smart guides |

| Safety Guidelines for Handling Linear Guides | operator safety |

| Cleaning Procedures for Linear Guide Rails | debris removal |

| How Linear Guides Improve Overall Machine Accuracy | rigidity |

| Top Manufacturers of Linear Guides | THK, Hiwin |

| Final Buying Checklist | purchase tips |

| Conclusion | summary |

Introduction

The term linear guide appears very early in this article to ensure clarity and SEO impact. Linear guides play a crucial role in modern machinery, enabling accurate, stable, and reliable motion in a straight line. Although the concept may sound highly technical, the principles behind linear guides are surprisingly simple. Transitioning from old sliding systems to modern linear guide technology boosts machine performance, improves accuracy, and ensures smoother operations.

To make this guide easy to follow, the writing uses simple words, human-like expressions, short sentences, and clear transitions. Let’s explore the world of linear guides with both practical insight and engineering experience.

Linear Guide Overview

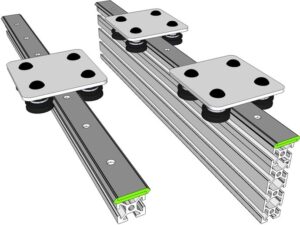

A linear guide is a mechanical system designed to enable straight, controlled, and low-friction motion. It typically includes a rail and a block (also called a carriage). Inside the block are balls or rollers that move smoothly along the rail.

Linear guides are essential for equipment that must repeat the same motion with high accuracy. They ensure smoother movement, better rigidity, and far less friction than traditional sliding systems.

Why Linear Guide Systems Matter

Linear guides matter because they solve several problems seen in older mechanisms:

They minimize friction

They provide consistent accuracy

They support heavy loads

They eliminate uneven motion

They improve machine lifespan

They reduce energy usage

Industries that require controlled movement depend on linear guide systems to ensure precise, reliable performance.

How a Linear Guide Works

A linear guide works by combining:

A hardened rail

A moving block

Rolling elements (balls or rollers)

Recirculating pathways inside the block

As motion occurs, the rolling elements circulate in a loop, allowing smooth travel without sticking. This reduces friction dramatically, producing a stable and predictable linear path.

Core Components of a Linear Guide

A standard linear guide contains:

Guide rail – the path of travel

Carriage/block – the moving body

Rolling elements – balls or rollers

End caps – guide circulation

Seals and wipers – keep contaminants out

Lubrication ports – maintain smooth travel

Each part contributes to accuracy and load-handling ability.

Types of Linear Guide Systems

The two major types include:

● Ball-type linear guides

● Roller-type linear guides

Other variations:

Miniature guides

Heavy-duty guides

Wide-body guides

Flanged blocks

Long-travel guides

Each type serves a specific purpose in precision motion systems.

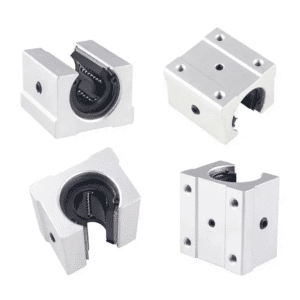

Ball-Type Linear Guide

Ball-type guides use recirculating balls inside the carriage. They offer:

Very smooth motion

Low friction

High speed

Quiet operation

Affordable cost

They work well for most automation applications.

Roller-Type Linear Guide

Roller guides use cylindrical rollers instead of balls. Benefits include:

Higher rigidity

Higher load capacity

Better moment resistance

Improved vibration control

They are widely used in CNC machining and heavy industrial machinery.

Miniature Linear Guide Systems

Miniature guides are compact and lightweight, yet incredibly accurate. They appear in:

Medical equipment

Small robots

Laboratory automation

Optical devices

Battery assembly machines

Despite their size, they provide excellent precision.

Heavy-Duty Linear Guides

Heavy-duty guides support tremendous loads. Their thicker rails and stronger rollers allow usage in:

Industrial cutting machines

Large CNC units

Robotic lifting systems

Heavy automation lines

Durability is their main advantage.

Linear Guides for CNC Machines

CNC machines depend on linear guides for:

Better rigidity

Smooth cutting motion

High-speed positioning

Repeatable accuracy

A CNC machine without linear guides loses precision quickly.

Linear Guides in Robotics

Robots use linear guides for:

Arm extension

Pick-and-place tasks

Manipulator systems

Automated assembly

The low friction and high accuracy improve robotic reliability.

Linear Guides in Automation Equipment

Automation lines use linear guides for:

Packaging

Sorting

Inspection

Material transport

Laser cutting

Their stability keeps automated machines running for years.

Advantages of Using a Linear Guide

Key advantages:

Stable movement

Low friction

High precision

Longer lifespan

Excellent load capacity

Easy maintenance

Quiet operation

Linear guides enhance both speed and accuracy.

Applications of Linear Guide Systems

You’ll find them in:

CNC machines

3D printers

Robotics

Pick-and-place machines

Semiconductor equipment

Medical imaging systems

Automation lines

They work wherever accuracy is essential.

How to Choose the Right Linear Guide

Factors to consider:

Load capacity

Accuracy class

Speed requirements

Stroke length

Operating environment

Material type

Maintenance access

Budget

Matching these factors prevents premature wear.

Installation Guidelines for Linear Guides

Steps include:

Clean the mounting surface

Check flatness

Position the rail

Tighten bolts gradually

Install the carriage

Check motion by hand

Lubricate before use

Proper installation ensures smooth performance.

Lubrication for Linear Guide Systems

Lubrication:

Removes friction

Reduces noise

Prevents corrosion

Improves lifespan

Use compatible lubricants such as:

Lithium grease

Light machine oil

High-speed synthetic lubricants

Follow manufacturer schedules.

Maintenance Best Practices

Maintenance involves:

Removing dust and debris

Checking wipers

Reapplying lubrication

Verifying alignment

Inspecting for wear

A few minutes of maintenance extends years of performance.

Common Problems With Linear Guides

Common issues include:

Noise during movement

Rough travel

Dry rolling elements

Misalignment

Contamination

Excess load

Rust formation

Most problems come from dirt or incorrect installation.

Troubleshooting Guideway Issues

If issues appear, check:

Lubrication levels

Straightness of rail

Debris around wipers

Bearing damage

Loose screws

Excessive load pressure

A small adjustment often solves the issue.

Linear Guide vs Linear Bearing

| Feature | Linear Guide | Linear Bearing |

|---|---|---|

| Motion | Rolling | Sliding or rolling |

| Accuracy | Very high | Moderate |

| Load support | High | Medium |

| Speed | Fast | Medium |

| Vibration resistance | High | Low |

Linear guides dominate when accuracy matters.

Materials Used in Linear Guide Rails

Materials include:

Stainless steel

Hardened steel

Carbon steel

Aluminum (light-duty)

Hardened steel rails are common due to durability.

Environmental Effects on Linear Guides

Harmful factors:

Dust

Coolant

Moisture

High heat

Chemicals

Metal shavings

Seals and protective covers help protect the guide.

Load Ratings and Performance

Load ratings include:

Static load

Dynamic load

Moment load

Correct load selection prevents deformation and failure.

Speed and Acceleration Features

Linear guides support high speed thanks to:

Low friction

Smooth surface finish

Strong bearing structure

Many automation systems rely on high-speed guides.

Cost Factors for Linear Guides

Cost depends on:

Material quality

Precision grade

Size and travel length

Type of rolling element

Brand reputation

Higher precision = higher price.

Innovations in Linear Guide Technology

Modern improvements include:

Smart lubrication indicators

Ultra-low friction coatings

Lightweight composite materials

Integrated sensors

Vibration-dampening blocks

Innovation continues as machines demand higher performance.

Safety Guidelines for Handling Linear Guides

Safety tips:

Handle with care

Wear gloves

Avoid impacts

Keep guides clean

Mount properly

Precision surfaces must stay undamaged.

Cleaning Procedures for Linear Guide Rails

Steps:

Remove dust

Use soft cloth

Apply mild solvent

Wipe dry

Relubricate

Test movement

Cleanliness equals accuracy.

How Linear Guides Improve Overall Machine Accuracy

Linear guides improve accuracy by:

Increasing rigidity

Reducing vibration

Minimizing friction

Maintaining straightness

Supporting stable travel

This is why they dominate CNC and robotics.

Top Manufacturers of Linear Guides

Major brands include:

THK

Hiwin

Bosch Rexroth

NSK

IKO

Igus

These companies produce globally trusted products.

Final Buying Checklist

Before buying, verify:

Guide size

Load rating

Stroke length

Rail material

Rolling element type

Seal protection

Lubrication access

Brand reputation

Warranty coverage

Budget fit

A good checklist prevents costly mistakes.

Conclusion

Linear guides play a powerful role in modern machinery. They deliver smooth, accurate, and stable linear motion, supporting everything from CNC machines to robotics and medical equipment. By choosing the right guide, installing it correctly, and maintaining it regularly, you ensure a longer lifespan and excellent performance.

This guide provides the clarity, depth, and practical knowledge needed to make confident decisions about linear guides.

FAQs

What is a linear guide used for?

It provides accurate and smooth straight-line motion in machinery and automation systems.

Do linear guides need lubrication?

Yes, lubrication reduces friction, prevents wear, and extends life.

What causes rough movement in a linear guide?

Rough motion usually comes from dust, misalignment, or dry bearings.

Which industries depend on linear guides?

CNC, robotics, packaging, semiconductor, medical devices, and automation.

How long do linear guides last?

With care and proper lubrication, they can last thousands of hours.

Are linear guides better than traditional sliding rails?

Yes, they offer greater precision, lower friction, and longer life.

Internal Link Suggestions

Linear bearings

Linear motion systems

Outbound Link Suggestions

Hiwin Linear Guide Catalog

THK Linear Motion Documentation

NSK Precision Guideway Products