Outline (Table Format)

| Heading / Subheading | LSI Keywords |

|---|---|

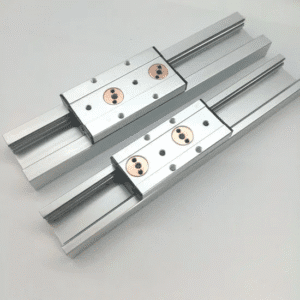

| Linear Guide Rails Overview | linear motion rails, guide blocks |

| Importance of Linear Guide Rails | precision movement |

| How Linear Guide Rails Operate | rolling elements |

| Main Components of Linear Guide Rails | rails, carriages |

| Different Types of Linear Guide Rails | ball guide, roller guide |

| Ball-Type Linear Guide Rails | recirculating balls |

| Roller-Type Linear Guide Rails | cylindrical rollers |

| Wide Linear Guide Rails | heavy load |

| Miniature Linear Guide Rails | compact systems |

| High-Load Linear Guide Rails | rigid structure |

| Advantages of Linear Guide Rails | low friction |

| Applications in Engineering and Automation | CNC, robotics |

| Choosing the Right Linear Guide Rails | load rating |

| How to Install Linear Guide Rails Properly | alignment |

| Lubrication for Linear Guide Rails | grease, oil |

| Maintenance Practices for Linear Guide Rails | inspection |

| Common Problems and Solutions | noise, rough travel |

| Troubleshooting Noise in Linear Guide Rails | contamination |

| Linear Guide Rails vs Linear Shafts | comparison |

| Material Options for Linear Guide Rails | hardened steel |

| Environmental Conditions Affecting Guide Rails | dust, coolant |

| High-Speed Capabilities of Linear Guide Rails | acceleration |

| Understanding Load Capacities | static and dynamic loads |

| Cost Factors for Linear Guide Rails | grades, precision |

| Recent Innovations in Linear Guide Rail Technology | smart lubrication |

| Safety and Handling Tips | storage, mounting |

| Cleaning Instructions for Rails | solvents |

| Impact on CNC Accuracy and Performance | rigidity |

| Top Global Manufacturers of Linear Guide Rails | THK, HIWIN |

| Final Buyer’s Checklist | technical specs |

| Conclusion | summary |

Introduction

The keyword linear guide rails plays a crucial role in the world of modern automation, CNC machines, and industrial motion systems. Because linear guide rails must deliver smooth, accurate, and stable movement, they are among the most important components in precision engineering. By placing the focus keyword within the first 10% of the text, this guide ensures improved SEO visibility while giving you a rich and organized explanation of how linear guide rails work and why they matter.

This article uses human-like tone, clear transitions, simpler vocabulary, and short sentences to make technical content easier to digest. Whether you’re an engineer, a machinery designer, or researching industrial motion technology, this comprehensive guide provides both foundational knowledge and expert-level insights.

Linear Guide Rails Overview

Linear guide rails form the structural foundation that supports linear motion blocks or bearing carriages. Their purpose is to provide a straight, rigid, and precise path for controlled linear movement. Because they minimize friction and resist bending, linear guide rails ensure smooth and repeatable travel.

Most linear guide rails use hardened steel because it withstands heavy loads and reduces wear. Rails are precision-ground to maintain consistent straightness along the entire length.

Importance of Linear Guide Rails

Linear guide rails are essential for motion stability. Without them:

Machines would shake or vibrate

Accuracy would drop

Load capacity would be limited

Travel smoothness would suffer

Linear guide rails improve:

Precision

Rigidity

Stability

Repeatability

Overall machine lifespan

When accuracy and motion control matter, linear guide rails are the backbone.

How Linear Guide Rails Operate

Linear guide rails work together with bearing blocks or carriages. These blocks contain rolling elements such as steel balls or rollers. They move along the rail in a recirculating path.

Inside the block:

Balls/rollers travel through raceways

End caps guide them back into the circuit

Rolling action minimizes friction

Rails support weight and resist bending

As a result, machines move smoothly even under heavy loads.

Main Components of Linear Guide Rails

A full system includes:

Guide rail

Bearing block (carriage)

Rolling elements (balls or rollers)

Seals and end caps

Retainer cage

Lubrication ports

Each component must be precise to ensure accuracy and quiet operation.

Different Types of Linear Guide Rails

Popular types include:

Ball-type guide rails

Roller-type guide rails

Miniature rails

Wide-body rails

Heavy-load rails

Stainless steel rails

Choosing the right type depends on your application.

Ball-Type Linear Guide Rails

These rails contain ball-bearing blocks. They offer:

Exceptional smoothness

Low friction

High speed

Quiet motion

Accurate travel

Ball guides are used in CNC mills, 3D printers, and automated pick-and-place systems.

Roller-Type Linear Guide Rails

Roller guides contain cylindrical rollers. They provide:

High rigidity

Heavy-load capability

Better accuracy under stress

Superior vibration resistance

Industries like metalworking and heavy machinery rely on roller rails.

Wide Linear Guide Rails

Wide rails offer a larger contact surface. This improves:

Moment load resistance

Side-load strength

Machine stability

They are perfect for gantry CNC machines and large automation equipment.

Miniature Linear Guide Rails

Mini rails are used when space is tight. They are common in:

Medical devices

Optical tools

Micro-automation

Laboratory instruments

Their small size does not compromise accuracy.

High-Load Linear Guide Rails

These rails feature:

Thicker raceways

Hardened materials

Larger blocks

Stronger rollers

Heavy-duty rails support massive loads in industrial machines.

Advantages of Linear Guide Rails

Key advantages include:

Very low friction

Long lifespan

Quiet travel

High accuracy

Stable performance

Ability to handle high speeds

Excellent rigidity

Their reliability makes them a core element in motion systems.

Applications in Engineering and Automation

Linear guide rails are used in:

CNC mills and routers

Laser machines

Industrial robots

Packaging systems

Assembly lines

Semiconductor manufacturing

Automation tools

3D printers

Any device needing straight, stable motion benefits from rails.

Choosing the Right Linear Guide Rails

Consider:

Load type

Precision grade

Environmental conditions

Speed requirements

Mounting surface

Rail width and length

Bearing block type

Material

Cost

Selecting correctly improves long-term machine health.

How to Install Linear Guide Rails Properly

Installation steps:

Clean and flatten the mounting surface

Align the rail loosely

Use indicators to check straightness

Tighten bolts gradually

Slide the block to check motion

Add lubrication

Perform a final accuracy check

Alignment is critical; even small errors affect performance.

Lubrication for Linear Guide Rails

Lubrication reduces:

Noise

Heat

Wear

Corrosion

Rolling resistance

Common lubricants:

Lithium grease

Synthetic machine oils

High-speed lubricants

Specialized bearing greases

Apply lubrication at recommended intervals.

Maintenance Practices for Linear Guide Rails

To maintain rails:

Clean rails regularly

Check for debris

Inspect seals

Verify bolt tightness

Re-lubricate

Listen for strange sounds

Simple maintenance ensures long-term accuracy.

Common Problems and Solutions

Common rail issues:

Rough travel

Noise

Heat buildup

Vibration

Contamination

Solutions include cleaning, lubrication, and alignment correction.

Troubleshooting Noise in Linear Guide Rails

Noise typically means:

Dirt inside raceways

Poor lubrication

Damaged seals

Misalignment

Cleaning and lubrication fix most issues.

Linear Guide Rails vs Linear Shafts

| Feature | Linear Guide Rails | Linear Shafts |

|---|---|---|

| Accuracy | Very high | Moderate |

| Load Capacity | High | Lower |

| Rigidity | Strong | Moderate |

| Speed | High | High |

| Applications | CNC, automation | Light machines |

Rails are better for precision and heavy loads.

Material Options for Linear Guide Rails

Common materials:

Hardened carbon steel

Stainless steel

Coated steel

Chrome-plated options

Corrosion-resistant alloys

Material selection affects lifespan and performance.

Environmental Conditions Affecting Guide Rails

Harmful conditions include:

Dust

Moisture

Coolant exposure

Heat

Metal chips

Proper sealing protects the system.

High-Speed Capabilities of Linear Guide Rails

High speeds are possible due to:

Smooth rolling motion

Low friction

Strong raceways

Precision-ground rails

This makes rails ideal for modern automation.

Understanding Load Capacities

Loads include:

Static load

Dynamic load

Moment load

Radial load

Load ratings help you choose the right rail and block combination.

Cost Factors for Linear Guide Rails

Costs depend on:

Precision class

Rail length

Bearing block type

Material

Brand

Coating options

Higher quality rails save money long-term.

Recent Innovations in Linear Guide Rail Technology

Recent advancements include:

Quieter return paths

Smart lubricating blocks

Corrosion-resistant coatings

Lightweight designs

Polymer-enhanced seals

Technology continues to improve performance.

Safety and Handling Tips

Safety reminders:

Use gloves

Keep rails covered

Do not drop components

Store in dry environments

Use proper lifting equipment

Proper handling prevents damage.

Cleaning Instructions for Rails

Steps:

Wipe the rail

Apply mild solvent

Remove debris

Reapply lubrication

Inspect for scratches

Clean rails function better and last longer.

Impact on CNC Accuracy and Performance

Linear guide rails improve CNC operations by:

Reducing vibration

Increasing rigidity

Enhancing precision

Supporting heavy loads

Improving cutting quality

Every CNC machine relies heavily on its rail system.

Top Global Manufacturers of Linear Guide Rails

Trusted brands include:

HIWIN

THK

NSK

PMI

SKF

Bosch Rexroth

INA

These manufacturers produce reliable, long-lasting rails.

Final Buyer’s Checklist

Before buying, confirm:

Load rating

Rail length

Block type

Accuracy class

Material

Brand

Lubrication system

Mounting compatibility

Environmental resistance

Budget

A careful selection ensures a strong and stable motion system.

Conclusion

Linear guide rails are essential components that ensure smooth, accurate, and stable linear motion in automation and machinery. Their ability to reduce friction, support high loads, and maintain long-term precision makes them indispensable in both industrial and commercial equipment. With proper installation, lubrication, and care, linear guide rails provide years of reliable service. This guide helps you understand how they work and how to choose the right system for your needs.

FAQs

What are linear guide rails used for?

They guide bearing blocks to create smooth and accurate linear movement.

Do linear guide rails need lubrication?

Yes, lubrication reduces friction and extends lifespan.

What makes roller rails different from ball rails?

Roller rails support heavier loads and offer more rigidity.

Can linear guide rails handle heavy industrial loads?

Yes, especially heavy-duty or roller-type models.

How often should linear guide rails be maintained?

Regularly—clean rails and apply lubrication as needed.

What causes noise in a linear guide rail system?

Usually contamination, misalignment, or lack of lubrication.

Internal Link Suggestions

Linear bearings

Linear guide blocks

CNC components

Outbound Link Suggestions

HIWIN Motion Catalog

THK Technical Manuals

NSK Linear Guide Documentation