Comprehensive Outline

| Main Topics | Detailed Coverage |

|---|---|

| Bearing Assemblies Overview | Definition and industrial importance |

| Evolution of Bearing Assemblies | From single bearings to integrated systems |

| Bearing Assemblies Fundamentals | Motion and load-handling principles |

| Core Components of Bearing Assemblies | Bearings, housings, seals |

| Types of Bearing Assemblies | Ball, roller, linear assemblies |

| Materials Used in Bearing Assemblies | Steel, alloys, polymers |

| Heat Treatment and Surface Finishing | Durability and wear resistance |

| Load Capacity and Distribution | Radial, axial, and moment loads |

| Precision and Alignment | Accuracy and stability |

| Bearing Assemblies vs Individual Bearings | System-level advantages |

| Installation and Mounting Methods | Best practices |

| Lubrication Systems | Grease, oil, and sealed units |

| Maintenance and Service Life | Reliability management |

| Vibration and Noise Control | Smooth operation |

| Bearing Assemblies in CNC Machines | Precision machining support |

| Automation and Robotics Applications | Reliable motion systems |

| Heavy Industrial Machinery | Load-intensive environments |

| Medical and Precision Equipment | Clean and accurate motion |

| Selecting the Right Bearing Assemblies | Technical considerations |

| Common Selection Mistakes | Oversizing and misalignment |

| Cost Efficiency and ROI | Long-term value |

| YH Linear Bearing Assemblies | Brand strengths |

| Future Trends in Bearing Assemblies | Smart and integrated solutions |

Introduction

Behind every smoothly operating machine lies a carefully engineered motion system. At the heart of many of these systems are bearing assemblies. Rather than using a single bearing alone, modern machinery increasingly relies on complete bearing assemblies that integrate bearings, housings, seals, and lubrication into one reliable unit.

At YH Linear, extensive experience in linear motion and mechanical systems has shown that high-quality bearing assemblies can significantly reduce downtime, simplify installation, and improve long-term performance. This article explores what bearing assemblies are, how they work, where they are used, and why they are essential in today’s industrial environment.

Bearing Assemblies

Bearing assemblies are pre-engineered units that combine one or more bearings with supporting components such as housings, seals, and lubrication systems. Their purpose is to support rotating or linear motion while managing loads, reducing friction, and maintaining alignment.

Unlike standalone bearings, bearing assemblies are designed as complete systems. This integration improves reliability and simplifies installation. In many cases, bearing assemblies also reduce the risk of misalignment and premature failure.

For manufacturers seeking consistency and efficiency, bearing assemblies provide a dependable solution.

Evolution of Bearing Assembly Technology

In early mechanical designs, bearings were installed individually and aligned manually. This approach required skilled labor and frequent adjustment.

As machinery became more complex, the need for standardized and reliable solutions increased. Bearing assemblies emerged as a way to combine critical components into a single, optimized unit.

Advancements in materials, sealing technology, and manufacturing precision have further improved modern bearing assemblies. Today, they are essential in industries that demand accuracy and durability.

Fundamental Principles of Bearing Assemblies

The core principle of bearing assemblies is controlled motion with reduced friction. Bearings within the assembly support loads while allowing smooth rotation or linear movement.

Load distribution is carefully engineered. Radial, axial, and moment loads are absorbed and transferred evenly through the housing and bearing elements.

Alignment is another key principle. By integrating bearings with precisely machined housings, bearing assemblies maintain correct positioning and reduce stress on components.

Core Components of Bearing Assemblies

A typical bearing assembly includes the bearing itself, a housing, seals, and a lubrication system.

The bearing may be a ball bearing, roller bearing, or linear bearing depending on application requirements. The housing provides structural support and ensures proper alignment.

Seals protect internal components from contamination, while lubrication channels or sealed grease systems ensure smooth operation over time. At YH Linear, each component is selected and assembled with strict quality control.

Types of Bearing Assemblies

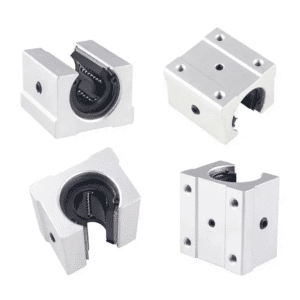

Bearing assemblies are available in many forms. Ball bearing assemblies are commonly used for moderate loads and high-speed applications.

Roller bearing assemblies offer higher load capacity and rigidity. Linear bearing assemblies guide straight-line motion in automation and machinery.

Each type serves a specific purpose, and selecting the right assembly ensures optimal performance and service life.

Materials and Surface Treatments

Material selection directly affects bearing assembly durability. High-strength alloy steels are widely used for their load capacity and wear resistance.

Surface treatments such as heat treatment, coating, or plating enhance hardness and corrosion resistance. These treatments are especially important in harsh industrial environments.

YH Linear bearing assemblies are designed with materials that balance strength, toughness, and longevity.

Load Capacity and Distribution

Bearing assemblies are engineered to handle complex load conditions. Radial loads act perpendicular to the shaft or motion path, while axial loads act along the axis.

Moment loads introduce torque that must be absorbed without deformation. Proper bearing assembly design ensures these forces are distributed evenly, preventing localized stress.

Correct load calculation is essential. YH Linear provides technical support to help customers choose assemblies that match their operating conditions.

Precision, Stability, and Alignment

Precision is a major advantage of bearing assemblies. Integrated housings ensure consistent alignment, reducing vibration and wear.

Stable alignment improves motion accuracy and extends service life. In precision machinery, this stability directly impacts product quality.

Bearing assemblies also reduce installation errors, providing predictable performance from the start.

Bearing Assemblies vs Individual Bearings

Compared to individual bearings, bearing assemblies offer easier installation and higher reliability. Components are pre-aligned and tested as a system.

This reduces assembly time and minimizes the risk of improper installation. Maintenance is also simplified, as complete units can be replaced when needed.

For many applications, bearing assemblies provide a more efficient and dependable solution.

Installation and Lubrication Practices

Proper installation ensures bearing assembly performance. Mounting surfaces must be flat and rigid.

Lubrication may be supplied through grease fittings, oil systems, or sealed-for-life designs. Consistent lubrication reduces friction and prevents corrosion.

Following recommended practices ensures smooth operation and long service life.

Applications of Bearing Assemblies

Bearing assemblies are used across countless industries. In CNC machines, they support spindles and linear motion systems.

Automation and robotics rely on bearing assemblies for smooth, repeatable movement. Heavy industrial machinery depends on them for load-bearing stability.

Medical and precision equipment benefit from their quiet and accurate operation. Their versatility makes bearing assemblies indispensable.

YH Linear Bearing Assemblies

YH Linear provides high-quality bearing assemblies designed for precision, durability, and reliability. Each assembly reflects deep industry knowledge and strict manufacturing standards.

By combining advanced engineering with responsive technical support, YH Linear delivers bearing assemblies that perform consistently in demanding applications.

Choosing YH Linear means choosing confidence and long-term value.

Future Trends in Bearing Assemblies

Future bearing assemblies will feature greater integration and intelligence. Sensors may be embedded to monitor temperature, load, and wear.

Improved materials and sealing technologies will further extend service life. As automation advances, bearing assemblies will continue to evolve.

YH Linear remains committed to innovation and continuous improvement.

FAQs

What are bearing assemblies used for?

They support and guide motion while managing loads and reducing friction.

How do bearing assemblies differ from individual bearings?

They integrate bearings with housings and seals for easier installation and higher reliability.

Are bearing assemblies suitable for heavy loads?

Yes, roller-type bearing assemblies handle heavy loads effectively.

Do bearing assemblies require maintenance?

Yes, proper lubrication and inspection extend service life.

Can bearing assemblies reduce vibration?

Yes, integrated alignment improves stability and reduces vibration.

Why choose YH Linear bearing assemblies?

YH Linear offers quality manufacturing, engineering expertise, and dependable performance.

Conclusion

Bearing assemblies are essential components in modern machinery, providing reliable motion, accurate alignment, and long service life. Their integrated design simplifies installation and enhances performance across industries.

With proven expertise and a commitment to quality, YH Linear continues to support manufacturers worldwide with dependable bearing assembly solutions. Selecting the right bearing assemblies today ensures efficiency, precision, and reliability for the future.

Suggested Internal Links

YH Linear bearing assembly product pages

YH Linear linear motion system solutions

Suggested Outbound Links

Industrial bearing standards organizations

Machinery design and maintenance resources