Outline for the Article on “Bearing Guide”

| Main Topic | Sub-Topics |

|---|---|

| Introduction to Bearing Guide | What is a bearing guide?, History of bearings, Importance in engineering |

| Fundamentals of Bearing Guide | Core purpose, Components, How bearing guides function |

| Types of Bearing Guides | Linear bearing guides, Roller bearing guides, Ball bearing guides, Plain bearing guides |

| Materials Used in Bearing Guides | Steel, Stainless steel, Polymer composites, Ceramic materials |

| Bearing Guide vs Standard Bearings | Differences, Advantages, When to use each |

| Applications of Bearing Guide | CNC machines, Aerospace, Robotics, Automotive, Medical devices |

| Benefits of Bearing Guide | Precision, Durability, Low friction, Versatility |

| Limitations of Bearing Guide | Cost considerations, Maintenance needs, Environmental factors |

| Installation of Bearing Guides | Tools required, Step-by-step process, Common mistakes |

| Maintenance and Care | Lubrication, Cleaning, Alignment checks |

| Innovations in Bearing Guides | Smart sensors, Nano-coatings, Self-lubricating systems |

| Choosing the Right Bearing Guide | Load capacity, Speed, Accuracy, Budget planning |

| Troubleshooting Common Issues | Noise problems, Excessive wear, Misalignment, Vibration |

| Bearing Guides in Robotics | Enhancing motion accuracy, Supporting automation, Precision in robotic arms |

| Bearing Guides in Aerospace | Lightweight materials, High-tolerance needs, Reliability under stress |

| Bearing Guides for DIY Projects | Maker projects, Home automation, Small CNC builds |

| Cost Factors in Bearing Guides | Industrial pricing, Budget options, Longevity vs. affordability |

| Environmental Impact | Recycling options, Sustainable materials, Eco-friendly lubrication |

| Future of Bearing Guides | AI-driven monitoring, Predictive maintenance, Magnetic levitation |

| Case Studies | Success in automotive, Medical innovations, Aerospace advancements |

| Standards and Certifications | ISO standards, Safety certifications, Industry benchmarks |

| Frequently Asked Questions | Addressing common concerns |

| Conclusion | Summary of importance, Future outlook |

| Suggested Inbound & Outbound Links | Internal and external linking recommendations |

Introduction to Bearing Guide

A bearing guide is a cornerstone of modern engineering, designed to ensure smooth, accurate, and efficient motion in mechanical systems. Whether in a small household appliance or a large industrial robot, bearing guides reduce friction, support loads, and enable precise movement.

The history of bearings dates back to ancient civilizations. The Egyptians used simple logs as rollers to move heavy stones, and Leonardo da Vinci later sketched early bearing concepts in his mechanical drawings. Over centuries, bearings evolved into highly sophisticated systems incorporating advanced materials and designs to meet the growing demands of industry.

Today, bearing guides are indispensable. From CNC machines that cut aircraft components to the robotic arms assembling cars, bearing guides make accurate, repeatable motion possible. Their importance lies not just in facilitating movement, but also in extending the lifespan of machines, reducing energy consumption, and ensuring product quality.

Bearing guides are more than just components—they are enablers of technological progress. Without them, the precision we see in aerospace, medicine, and robotics would simply not exist.

Fundamentals of Bearing Guide

A bearing guide is designed to reduce friction and provide controlled, stable movement, either rotational or linear, depending on its type. At its simplest, it is a component that supports and directs motion while carrying loads. What makes a bearing guide so important is its ability to deliver precision and reliability under demanding conditions.

Core Purpose

The main purpose of a bearing guide is to enable smooth and efficient motion. Without it, machines would face high friction, excessive heat, and rapid wear, all of which would shorten their lifespan and compromise accuracy.

Key Components

Bearing elements: Balls, rollers, or sliding surfaces that carry the load.

Raceways or tracks: Precision-ground surfaces where the rolling elements move.

Cage or housing: Holds the rolling elements in place and ensures uniform spacing.

Seals and lubrication system: Protects against contamination and reduces friction.

How Bearing Guides Function

The functioning of a bearing guide depends on its design. In ball-bearing guides, spherical balls roll between tracks, providing point contact for low-friction motion. In roller guides, cylindrical rollers make line contact, distributing loads more effectively. Plain bearing guides, by contrast, rely on sliding contact with self-lubricating materials.

By reducing friction, bearing guides not only ensure smoother motion but also lower energy consumption. This efficiency translates into better machine performance and reduced operational costs across industries.

Types of Bearing Guides

Bearing guides are not one-size-fits-all solutions. Different types exist to meet the unique needs of diverse industries.

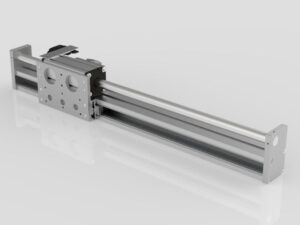

Linear Bearing Guides

These guides enable straight-line motion with high accuracy. They are widely used in CNC machines, 3D printers, and robotics. With rolling elements moving along guide rails, they offer excellent precision and repeatability.

Roller Bearing Guides

Using cylindrical rollers instead of balls, roller guides provide higher load capacity and rigidity. They are ideal for heavy-duty industrial machinery and applications requiring strong resistance to deformation.

Ball Bearing Guides

These are the most common type, featuring spherical balls that roll between two raceways. Their main advantage is low friction, making them suitable for applications requiring speed and efficiency rather than heavy load handling.

Plain Bearing Guides

Instead of rolling elements, plain guides rely on sliding surfaces, often made of self-lubricating polymers or bronze. They are cost-effective and quiet, frequently used in medical equipment and household devices.

Each type of bearing guide brings its own strengths. Engineers must select based on factors such as load requirements, operating speed, environmental conditions, and desired accuracy.

Materials Used in Bearing Guides

The performance and longevity of a bearing guide largely depend on the materials chosen in its construction. These materials determine durability, weight, corrosion resistance, and even cost.

Steel

Hardened steel is the standard material for many bearing guides. It provides exceptional strength and wear resistance, making it suitable for heavy loads and industrial use.

Stainless Steel

In corrosive environments—such as food processing plants, marine equipment, or medical devices—stainless steel is the go-to material. It combines strength with rust resistance.

Polymer Composites

For lightweight, quiet, and maintenance-free applications, polymer-based bearing guides are used. They are self-lubricating and corrosion-resistant, though not as strong as metal alternatives.

Ceramic Materials

Ceramic bearings are lightweight, harder than steel, and resistant to extreme heat. They are used in aerospace, robotics, and high-speed applications where performance and precision are critical.

Material choice often reflects a balance between performance and cost. For example, an aerospace project may require hybrid ceramic bearings for ultimate performance, while a budget-conscious automation system might choose steel or polymer-based guides.

Bearing Guide vs Standard Bearings

Though both terms—bearing guide and standard bearing—are often used interchangeably, they serve slightly different functions.

Standard Bearings

These typically support rotary motion, such as in wheels, motors, or turbines. Their job is to minimize friction between a rotating shaft and its housing.

Bearing Guides

These not only reduce friction but also direct or constrain movement along a path, whether linear or rotational. A bearing guide adds the element of “guidance,” ensuring precise and repeatable motion.

Key Differences

Guidance function: Bearing guides provide directional control, while standard bearings focus mainly on rotation.

Applications: Standard bearings are common in automotive wheels and engines, while bearing guides dominate CNC, robotics, and automation.

Load handling: Roller and linear guides often handle heavier loads due to their design.

In essence, all bearing guides are bearings, but not all bearings qualify as bearing guides. The distinction lies in the added function of controlled movement.

Applications of Bearing Guide

The versatility of a bearing guide makes it indispensable across industries. From precision instruments to massive industrial systems, bearing guides ensure smooth and reliable motion.

CNC Machines

In computer numerical control (CNC) machines, accuracy is everything. Bearing guides enable tool heads to move with micron-level precision, ensuring that parts are cut, drilled, or milled exactly to specification. Without them, modern machining centers would lose their reliability and efficiency.

Aerospace Industry

Bearing guides play a critical role in aerospace applications, where safety and performance are non-negotiable. From controlling navigation instruments to ensuring smooth movement in wing flaps or satellite components, bearing guides withstand extreme loads, temperatures, and stresses.

Robotics

Robotic systems rely heavily on bearing guides to execute repeatable, accurate motions. Whether assembling microchips, welding automotive frames, or performing delicate medical procedures, robots depend on bearing guides to achieve precision and consistency.

Automotive Manufacturing

In vehicle assembly lines, bearing guides enable smooth and efficient movement of robotic arms, conveyor systems, and testing machinery. They also appear in the vehicles themselves, particularly in steering and suspension systems.

Medical Devices

In MRI machines, surgical robots, and diagnostic equipment, bearing guides are essential. Here, they must deliver silent, vibration-free operation while meeting strict hygiene standards. Polymer and stainless-steel bearing guides are commonly used in this field.

The adaptability of bearing guides is what makes them so valuable. From heavy machinery to delicate instruments, they prove their worth in both durability and precision.

Benefits of Bearing Guide

The widespread use of bearing guides is no accident—they offer numerous benefits that enhance machine performance and reduce operating costs.

Precision and Accuracy

Bearing guides allow machines to achieve consistent, repeatable motion. This is critical in sectors like aerospace and medical imaging, where a fraction of a millimeter can make a major difference.

Durability and Long Life

Built from high-quality materials such as hardened steel, stainless steel, or ceramics, bearing guides are designed to withstand heavy loads and harsh conditions. With proper maintenance, they can last for years.

Low Friction

By reducing the resistance between moving parts, bearing guides improve efficiency and reduce energy consumption. This not only saves costs but also prevents heat buildup that could damage components.

Versatility

From lightweight polymer bearings for clean medical environments to heavy-duty roller guides for industrial systems, bearing guides cover a wide range of needs. Their adaptability ensures they fit seamlessly into countless applications.

Reduced Downtime

With smoother motion and reliable performance, bearing guides minimize wear and tear. This reduces unexpected breakdowns and keeps production systems running longer with less maintenance.

All these benefits combine to make bearing guides an irreplaceable part of modern mechanical systems, helping industries achieve the balance of efficiency, precision, and cost-effectiveness.

Limitations of Bearing Guide

Despite their many advantages, bearing guides also come with limitations that engineers must consider when designing or selecting them.

Cost Considerations

High-performance bearing guides, especially those made of ceramic or hybrid materials, can be expensive. While they deliver superior performance, the cost may be prohibitive for budget-sensitive projects.

Maintenance Needs

Most bearing guides require regular lubrication and cleaning to perform at their best. If neglected, friction increases, leading to premature wear and system failure.

Environmental Sensitivity

Dust, dirt, moisture, and chemicals can significantly reduce a bearing guide’s efficiency. Special seals or coatings may be required in challenging environments, adding to the overall cost.

Installation Challenges

Proper installation is critical. Misalignment or over-tightening during installation can damage the bearing guide, reduce its lifespan, and compromise precision.

By acknowledging these limitations upfront, engineers can take preventive measures—choosing the right type, using protective covers, and implementing proper maintenance schedules.

Installation of Bearing Guides

Installing a bearing guide correctly is just as important as choosing the right one. Poor installation can result in misalignment, excessive wear, and costly downtime.

Tools Required

Torque wrench

Alignment gauge

Clean workspace and lint-free cloths

Lubrication oil or grease

Step-by-Step Process

Preparation – Clean the guide rail and work area to prevent contamination.

Positioning – Carefully place the bearing guide onto the rail, ensuring it slides smoothly without forcing.

Securing – Use the recommended torque to tighten bolts evenly. Over-tightening can distort the housing.

Alignment Check – Move the carriage manually to ensure smooth, resistance-free travel.

Lubrication – Apply the appropriate lubricant based on manufacturer specifications.

Common Mistakes to Avoid

Skipping lubrication or using the wrong type.

Allowing dust or debris during installation.

Uneven tightening of bolts, leading to misalignment.

Proper installation ensures that the bearing guide operates at peak performance and lasts longer, saving both time and money in the long run.