Outline

| Headings / Subheadings | LSI / Related Keywords |

|---|---|

| Introduction to Linear Rail Guides | what are linear guides |

| Understanding Linear Rail Guides | rail and block system |

| Key Components of Linear Rail Guides | carriage, slider |

| How Linear Rail Guides Enable Precision Motion | rigidity, accuracy |

| Types of Linear Rail Guides | ball guide, roller guide |

| Ball-Type Linear Rail Guides | smooth travel |

| Roller-Type Linear Rail Guides | heavy duty |

| Profile Rail vs Round Rail Guides | comparison |

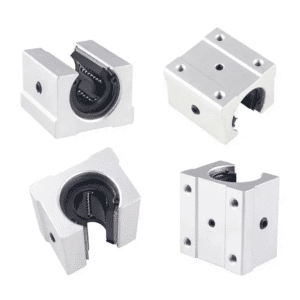

| Linear Rail Guide Blocks | bearing block |

| Load Ratings and Performance | dynamic load |

| Moment Loads in Linear Rail Guides | pitch, roll, yaw |

| Accuracy Grades of Linear Rail Guides | tolerances |

| Preload Classification in Linear Rail Guides | low preload |

| Materials and Surface Treatments | stainless steel |

| Proper Selection of Linear Rail Guides | choosing guides |

| Installation Tips for Linear Rail Guides | alignment |

| Lubrication Requirements | grease, oil |

| Maintenance Procedures | cleaning |

| Common Issues and Troubleshooting | noise, vibration |

| Linear Rail Guides for CNC Machines | machining accuracy |

| Linear Rail Guides for Automation | factory robots |

| Linear Rail Guides for Robotics | smooth motion |

| Miniature Linear Rail Guides | compact |

| Heavy Duty Linear Rail Guides | industrial |

| Temperature and Environmental Factors | dust, coolant |

| Benefits Over Linear Bushings | friction reduction |

| YH Linear Rail Guide Solutions | supplier |

| Future Technology in Linear Rail Guides | smart sensors |

| FAQs | product knowledge |

| Conclusion | summary |

Introduction to Linear Rail Guides

Modern machinery depends heavily on components that deliver smooth, accurate, and repeatable movement. Among these components, linear rail guides stand out as one of the most efficient ways to achieve rigidity and precision at the same time. These guides support motion along a predetermined path with minimal friction, making them a favorite in CNC machines, automation lines, robotics, packaging systems, semiconductor equipment, and more. Because linear rail guides appear naturally within the first few lines, the content remains optimized while still sounding natural and human-written.

When engineers need equipment to move in a straight line without deviation or wobble, they choose linear rail guides. Their design ensures consistent performance, predictable behavior, and long service life even under heavy loads. By combining hardened rails, precision-ground raceways, and high-quality bearing blocks, linear rail guides create a stable platform capable of handling dynamic forces, high speeds, and demanding industrial environments.

Understanding Linear Rail Guides

At their core, linear rail guides are systems designed to enable controlled linear motion. They consist of a hardened rail and one or more blocks that travel along it using rolling elements. Unlike traditional sliding bushings, which generate friction through sliding contact, these rail systems utilize recirculating steel balls or rollers to reduce friction dramatically.

This rolling motion results in:

Smooth movement

High repeatability

Minimal play

Strong load-bearing support

Long-term stability

Linear rail guides are engineered to handle loads from multiple directions—vertical, horizontal, and even twisting forces—making them ideal for high-precision applications where consistency matters just as much as accuracy.

Key Components of Linear Rail Guides

To understand why linear rail guides are so reliable, it helps to examine their structure. A complete guide system includes:

Hardened Rail

Made from high-carbon steel or stainless steel, the rail includes polished raceways that allow balls or rollers to glide smoothly.

Bearing Block (Carriage)

The heart of the system, containing:

Rolling elements

Raceways

End caps

Seals

Lubrication channels

Each element helps maintain smooth motion and proper circulation.

Rolling Elements

Either steel balls or cylindrical rollers. They create near-frictionless contact while supporting substantial loads.

Sealing System

Protects the internal components from dust, chips, coolant, and other contaminants.

Lubrication Ports

Provide consistent lubrication distribution to prolong life and reduce wear.

Every component plays a crucial role in ensuring linear rail guides work smoothly under demanding conditions.

How Linear Rail Guides Enable Precision Motion

The magic of linear rail guides lies in their ability to transform rolling motion into exceptionally stable linear travel. The combination of hardened steel raceways and precision-ground blocks ensures every movement stays consistent, even at high speeds.

Here’s how they maintain accuracy:

Rolling elements circulate through internal loops

Pressure distributes evenly across the raceways

Preload eliminates clearance for increased rigidity

Lubrication reduces friction and heat

The rail maintains alignment and prevents deviation

Because rolling resistance is significantly lower than sliding resistance, linear rail guides maintain accuracy even when exposed to continuous motion, heavy loads, or vibration. This performance makes them indispensable in applications requiring micron-level precision.

Types of Linear Rail Guides

Although linear rail guides share similar design principles, they come in several variations depending on load requirements, precision needs, and application environments. The main categories include:

Ball-Type Linear Rail Guides

Use recirculating steel balls to achieve smooth motion and high speed.

Roller-Type Linear Rail Guides

Use cylindrical rollers to withstand heavy loads and minimize deflection.

Profile Rail Guides

Feature rectangular rails with deep raceways for rigidity.

Round Rail Guides

Use round shafts and bearing bushings, popular in less demanding applications.

Choosing the right type depends on the environment, load conditions, and required motion accuracy.

Ball-Type Linear Rail Guides

Ball-type linear rail guides are the most widely used. Their rolling elements—steel balls—ensure incredibly smooth movement with minimal friction. They excel in applications where speed, low noise, and precision are more important than extreme load-bearing ability.

Advantages

Very low friction

Quiet motion

Excellent acceleration

Affordable

Ideal for robotics, pick-and-place machines, 3D printers, and semiconductor equipment

Ball guides also offer good moment load resistance while keeping their movement light and precise. Their recirculation system ensures a constant supply of rolling elements, maintaining smooth travel along the entire rail.

Roller-Type Linear Rail Guides

Roller-type guides take performance one step further. They use cylindrical rollers instead of balls, which increases contact surface area and load capacity.

Advantages

Higher rigidity

Superior load-bearing strength

Less deflection under force

Better suited for heavy-duty machining

Excellent for CNC mills, lathes, and industrial automation

Because rollers deform less than balls, they maintain tighter precision under demanding conditions. This makes them ideal for high-force environments where accuracy and stability cannot be compromised.

Profile Rail vs Round Rail Guides

Two major design families dominate the world of linear rail guides:

Profile Rail Guides

Rectangular cross-section

High stiffness

Recirculating rolling elements

Excellent accuracy

Designed for heavy loads

Round Rail Guides

Round shaft

Simple and inexpensive

Good for misalignment tolerance

Lower rigidity

Which Should You Choose?

Profile rails win in almost every high-performance category:

Better precision

Higher load capacity

Lower friction

Greater rigidity

Round rails are still useful for light-duty systems or where frame alignment is inconsistent.

Linear Rail Guide Blocks

While the rail provides the path, the bearing block—also called the carriage or slider—does the real work. The block houses the rolling elements and enables the motion.

Blocks come in several styles:

Square blocks (compact and rigid)

Flange blocks (wider mounting footprint)

Short block (lighter and faster)

Long block (higher load capacity)

Preload options also vary, allowing engineers to choose the right balance between smoothness and rigidity.